Liquid crystal display element and method for manufacturing same

A technology for liquid crystal display elements and liquid crystal layers, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of reduced transmittance, different response speeds of liquid crystal molecules, and insufficient response speeds, and achieve good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

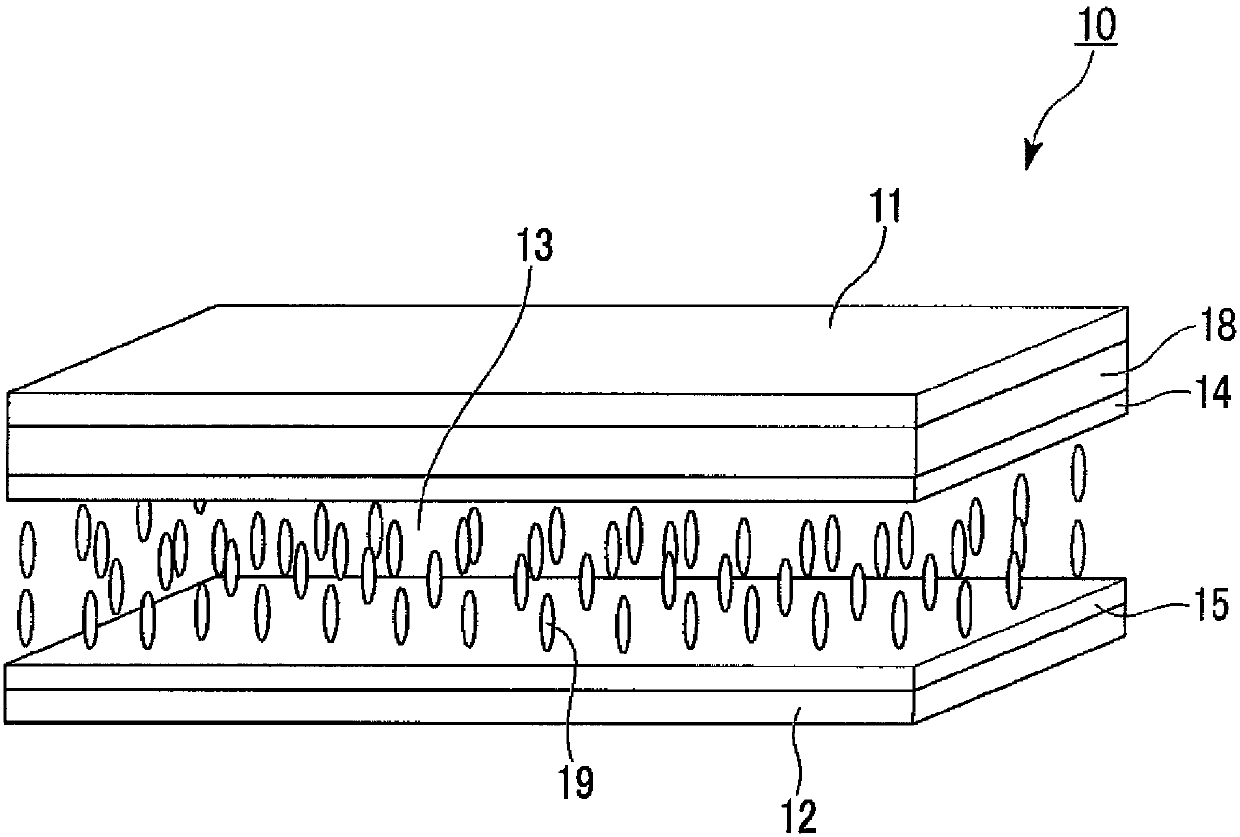

[0308] Fabricate a first substrate (common electrode substrate) and a second substrate (pixel electrode substrate), the first substrate (common electrode substrate) has a transparent electrode layer and a color filter layer made of transparent common electrodes, the second substrate (Pixel electrode substrate) includes a pixel electrode layer having a transparent pixel electrode driven by an active element. Liquid crystal composition LC-1 containing a compound selected from the general formula (I) and a compound selected from the general formula (II) was prepared. The constituent compounds and the contained ratios are as follows.

[0309] [chem 38]

[0310]

[0311] For the liquid crystal composition LC-1 98.08wt%, add 1.5wt% of the polymerizable compound shown below,

[0312] [chem 39]

[0313]

[0314] Add 0.32wt% of the polymerizable compound shown below,

[0315] [chemical 40]

[0316]

[0317] And add 0.1wt% photopolymerization initiator Igacure651, and diss...

Embodiment 2

[0325] In the same experiment as in Example 1, 98.5 wt% of the liquid crystal composition LC-1 was added with 1.0 wt% of the polymerizable compound shown below,

[0326] [chem 41]

[0327]

[0328] Add 0.4wt% of the polymerizable compound shown below,

[0329] [chem 42]

[0330]

[0331] Furthermore, 0.1 wt % of photopolymerization initiator Igacure 651 was added and uniformly dissolved to prepare the polymerizable liquid crystal composition CLC-1a.

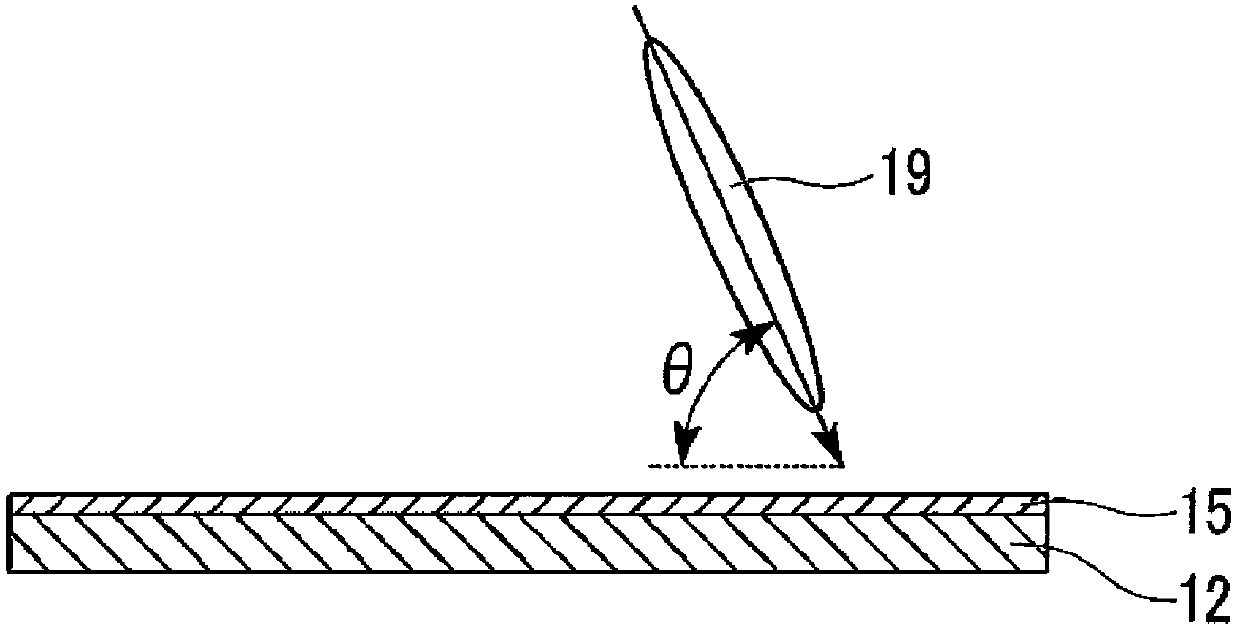

[0332]After the polymerizable liquid crystal composition CLC-1a was sandwiched between the common electrode substrate and the pixel electrode substrate not having an alignment film layer, the sealing material was cured to form a liquid crystal composition layer. At this time, a spacer having a thickness of 3.2 μm was used to make the thickness of the liquid crystal composition layer 3.2 μm. Ultraviolet rays are irradiated to the obtained liquid crystal display in a state where a voltage is applied to cure the polymerizab...

Embodiment 3

[0345] In the same experiment as in Example 1, the liquid crystal composition used was changed to liquid crystal composition LC-2 containing the compound selected from the general formula (I) and the compound selected from the general formula (II). The constituent compounds and the contained ratios are as follows.

[0346] [chem 43]

[0347]

[0348] For the liquid crystal composition LC-2 97.7wt%, add 1.8wt% of the polymerizable compound shown below,

[0349] [chem 44]

[0350]

[0351] Add 0.4wt% of the polymerizable compound shown below,

[0352] [chem 45]

[0353]

[0354] Furthermore, 0.1 wt % of photopolymerization initiator Igacure 651 was added and uniformly dissolved to prepare a polymerizable liquid crystal composition CLC-2.

[0355] After the polymerizable liquid crystal composition CLC-2 was sandwiched between the common electrode substrate and the pixel electrode substrate not having an alignment film layer, the sealing material was cured to form a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com