Nanowire p-n heterojunction and preparation method thereof

A nanowire and heterojunction technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as expensive equipment, difficulty in obtaining templates, and difficulty in preparing high-purity samples, achieving rapid preparation and overcoming difficulties in obtaining , Preparation of economical and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a nanowire p-n heterojunction, comprising the following steps:

[0027] Mixing p-type quantum dots with conductive polymers and benzene organic solvents to obtain a mixed solution doped with p-type quantum dots;

[0028] Mixing n-type quantum dots with conductive polymers and benzene organic solvents to obtain a mixed solution doped with n-type quantum dots;

[0029] Pulling the mixed solution doped with p-type quantum dots to obtain p-type nanowires;

[0030] Pulling the mixed solution doped with n-type quantum dots to obtain n-type nanowires;

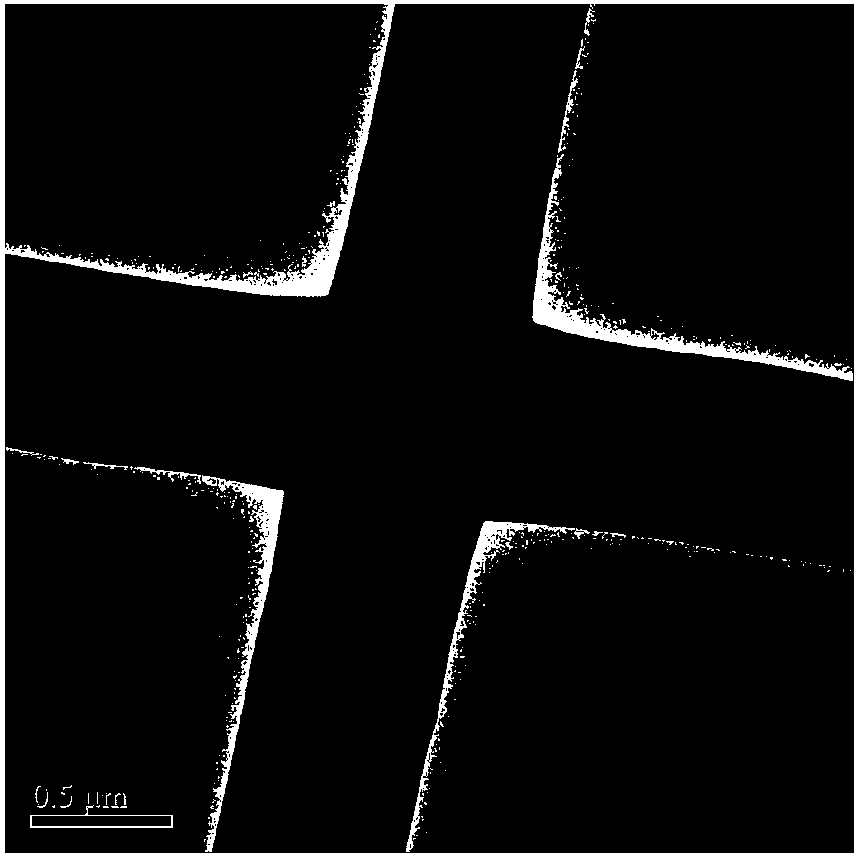

[0031] Under an optical microscope, the p-type nanowire and the n-type nanowire are micro-manipulated to obtain a cross structure, which is a nanowire p-n heterojunction.

[0032] The invention mixes p-type quantum dots with conductive polymers and benzene organic solvents to obtain a mixed solution doped with p-type quantum dots. In the present invention, the p-type quantum dots...

Embodiment 1

[0052] Dissolve 880mg of polyaniline in 1mL of xylene solvent to form a homogeneous polyaniline xylene solution.

[0053] Add 450 μL of p-type / n-type CdSe-ZnS core-shell quantum dot xylene solution (concentration: 2 μmol / L) into 1 mL of prepared polyaniline xylene solution, stir at room temperature for 2 hours, and then sonicate for 40 minutes , to obtain a mixed solution doped with p or n type quantum dots.

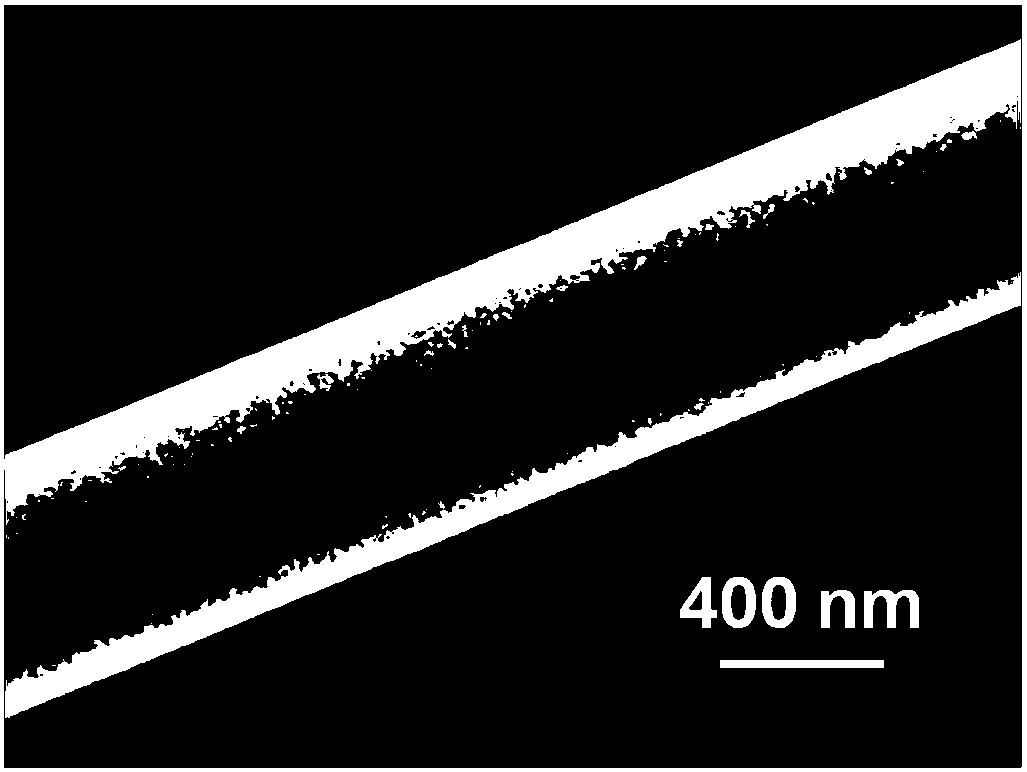

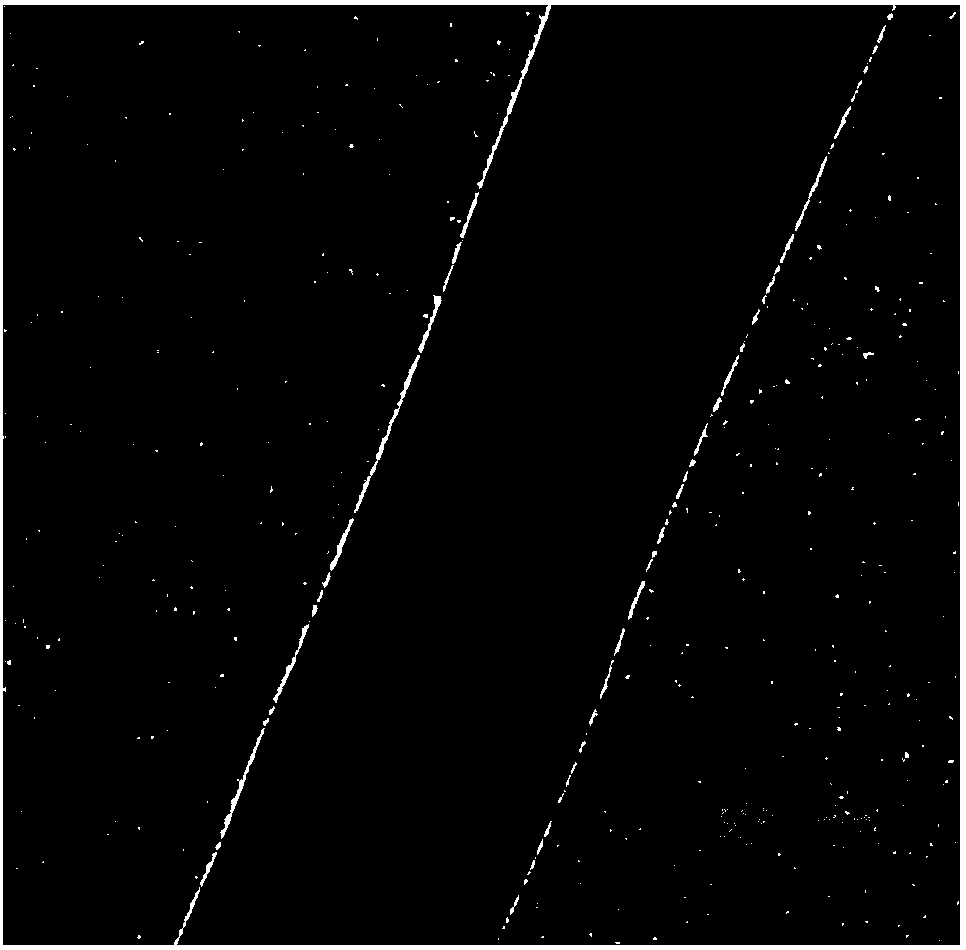

[0054] Immerse the glass fiber optic cone (tip diameter 10 microns) in the mixed solution of p or n-type quantum dots for 1 second, and pull the glass fiber optic cone at 0.1m / s, so that the polyaniline between the light cone tip and the solution can be obtained. Nanowires (doped with quantum dots). With the rapid evaporation of the xylene solution, a quantum dot-doped polyaniline nanowire is pulled out to obtain p-type nanowires and n-type nanowires.

[0055] Under an optical microscope (magnification 50, numerical aperture 0.7), firstly fix a p-type nanowire, and the...

Embodiment 2

[0059] Dissolve 620mg of polyaniline in 0.7mL of xylene solvent to form a homogeneous polyaniline xylene solution.

[0060] Add 250 μL p-type / n-type CdSe-ZnS core-shell quantum dot xylene solution (concentration: 4 μmol / L) into 0.7 mL polyaniline xylene solution, stir at room temperature for 2 hours, and then sonicate for 40 Minutes, a mixed solution doped with p or n type quantum dots is obtained.

[0061] Immerse the glass fiber cone (30 microns in tip diameter) in the mixed solution of p or n-type quantum dots for 4 seconds, and pull the glass fiber cone at 3m / s, so that the polyaniline nanometer between the tip of the light cone and the solution can be obtained. wire (with quantum dots doped in it). With the rapid evaporation of the xylene solution, a quantum dot-doped polyaniline nanowire is pulled out to obtain p-type nanowires and n-type nanowires.

[0062] Under an optical microscope (magnification 50, numerical aperture 0.7), first fix an n-type nanowire, and then u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com