Hydroxyl oxidize iron-nickel-iron hydrotalcite integrated oxygen evolution electrode and preparation method and application thereof

A technology of iron oxyhydroxide and oxygen evolution electrode, which is applied in the direction of electrodes, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., and can solve the problems that cannot be overcome by catalysts and affect the long-term operation life of the full electrolytic cell, corrosion etc. to achieve good catalytic activity and stability, good performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] preparation:

[0034] (1) Mixing of precursor solution: with 0.261g nickel nitrate, 0.5g iron nitrate as raw material, 0.2g urea as alkali source; 1.5g polyethylene glycol as surfactant; 0.2g ammonium fluoride as complexing agent; Dissolve in 40mL deionized water and stir for 30min;

[0035] (2) Hydrothermal reaction: Transfer the solution of (1) to a 50mL hydrothermal reaction kettle with a nickel foam base, and conduct a hydrothermal reaction at 120°C in a blast drying oven for 5 hours. The hydrothermal kettle is cooled with the furnace to prepare Get dark green nickel foam. Washing with deionized water for 3 to 5 times, and drying in vacuum at 60°C for 8 hours to prepare an integrated oxygen evolution electrode of iron oxyhydroxide / nickel-iron hydrotalcite (FeOOH / NiFe LDHs).

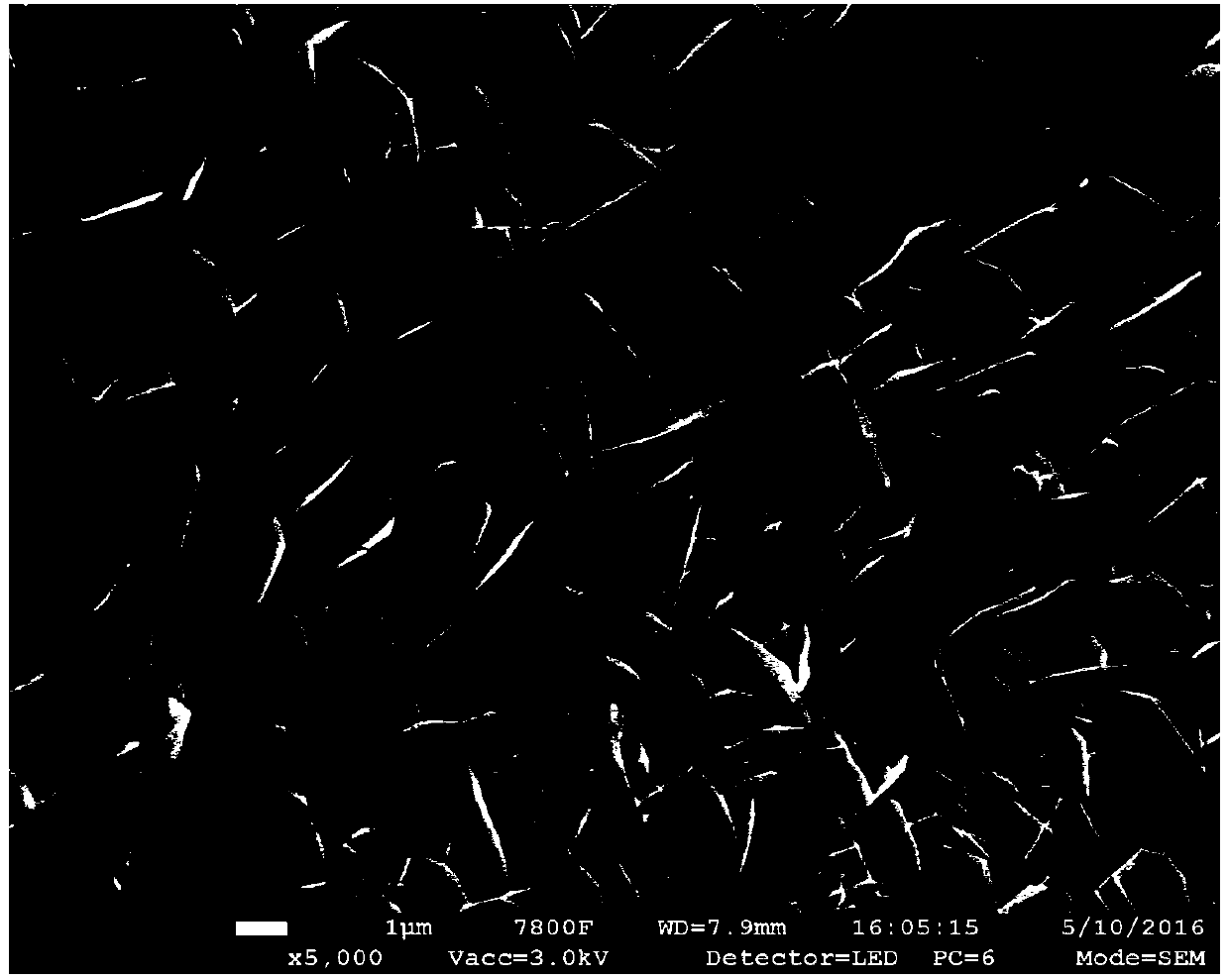

[0036] Depend on figure 1 It can be seen that the integrated electrode with uniform size, good dispersion, 0.5-8 μm high, 10-50 nm thick vertical and intersecting nanosheet layers loaded on ...

Embodiment 2

[0039] The iron hydroxide integrated electrode was prepared according to the same preparation steps as in Example 1, the amount of nickel nitrate in the precursor was 0.7 g, and the test conditions were the same as in Example 1.

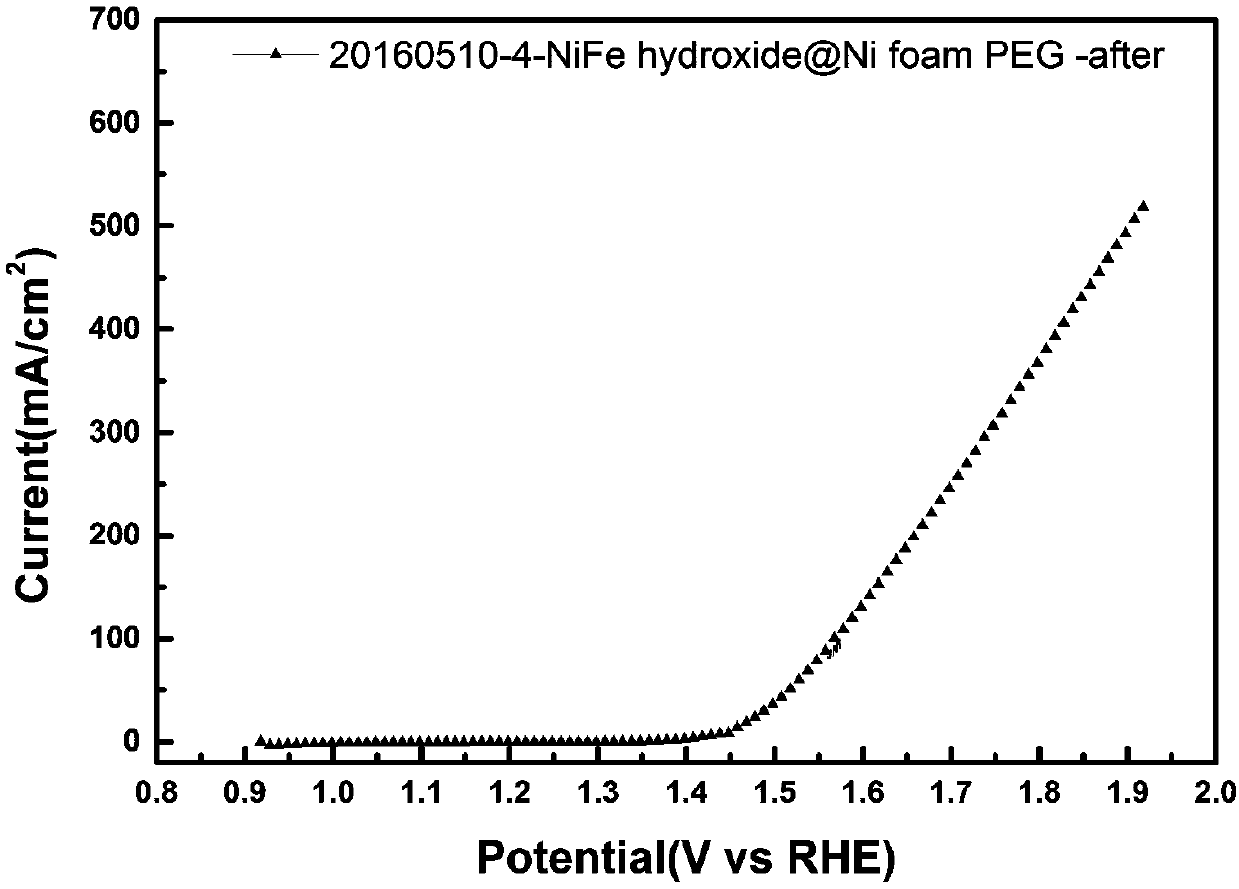

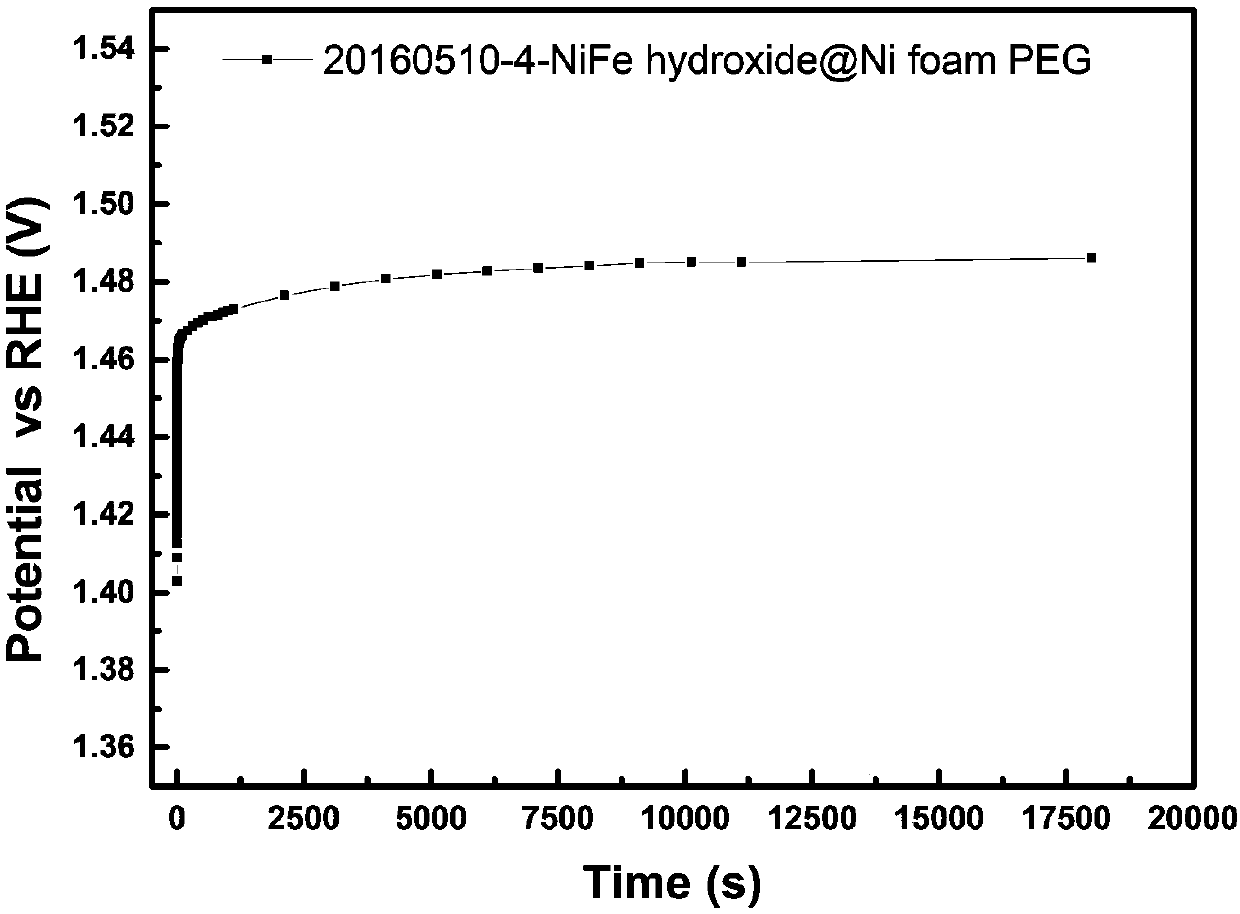

[0040] Half-cell test: The half-cell system uses 1M KOH solution saturated with oxygen as the electrolyte, and the integrated electrode performs LSV scanning, such as figure 2 , 3 shown. The integrated electrode prepared by this method is 100mA / cm in 1M KOH electrolyte solution 2 The potential under the electrolysis current density is 1.594V (vs.RHE).

Embodiment 3

[0042] The nickel hydroxide integrated electrode was prepared according to the same preparation steps as in Example 1, the amount of nickel nitrate in the precursor was 0.8 g, and the test conditions were the same as in Example 1.

[0043] Half-cell test: The half-cell system uses 1M KOH solution saturated with oxygen as the electrolyte, and the integrated electrode performs LSV scanning, such as figure 2 , 3 shown. The integrated electrode prepared by this method is 100mA / cm in 1M KOH electrolyte solution 2 The potential at the electrolysis current density is 1.678V (vs.RHE).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com