Heat-preservation and decoration integrated plate

A technology for thermal insulation boards and decorative boards, which is applied in covering/lining, construction, building structure, etc., can solve the problems of organic thermal insulation materials failing to meet the requirements of fire resistance, poor thermal insulation performance and waterproof performance, and single function, and achieve thermal insulation. Good effect, excellent thermal insulation, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

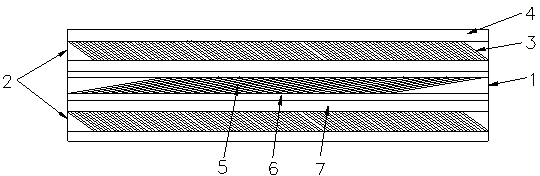

[0017] In this embodiment, the insulating material components in the insulating material layer 7 include 10 parts by weight of modified graphite, 3 parts of airgel, 1 part of accelerator, 3 parts of methylcellulose, 5 parts of silicon micropowder, zeolite powder 3 parts, 1 part of hollow glass microspheres, 2 parts of expanded perlite, 3 parts of sodium silicate.

[0018] In this embodiment, the 4 components of the decorative layer include 10 parts by weight of hot-melt resin, 10 parts of silicone acrylic emulsion, 4 parts of inorganic thickener, 2 parts of flexible plant fiber, 1 part of titanium dioxide, and a foaming agent. 3 parts, diatomaceous earth 5 parts, ultraviolet absorber 2 parts.

[0019] In this embodiment, the board body 3 is a polystyrene-polyplastic board.

Embodiment 2

[0021] In this embodiment, the insulating material components in the insulating material layer 7 include 20 parts by weight of modified graphite, 12 parts of airgel, 4 parts of accelerator, 6 parts of methyl cellulose, 12 parts of silicon micropowder, zeolite powder 8 parts, hollow glass microspheres 4 parts, expanded perlite 6 parts, sodium silicate 9 parts.

[0022] In this embodiment, the 4 components of the finishing layer include 20 parts by weight of hot-melt resin, 20 parts of silicone acrylic emulsion, 16 parts of inorganic thickener, 8 parts of flexible plant fiber, 8 parts of titanium dioxide, foaming agent 8 parts, diatomaceous earth 12 parts, ultraviolet absorber 8 parts.

[0023] In this embodiment, the board body 3 is a polyurethane foam board.

Embodiment 3

[0025] In this embodiment, the insulating material components in the insulating material layer 7 include 12 parts by weight of modified graphite, 4 parts of airgel, 2 parts of accelerator, 4 parts of methylcellulose, 6 parts of silicon micropowder, zeolite powder 4 parts, hollow glass microspheres 2 parts, expanded perlite 3 parts, sodium silicate 4 parts.

[0026] In this embodiment, the 4 components of the finishing layer include 12 parts by weight of hot-melt resin, 12 parts of silicon acrylic emulsion, 6 parts of inorganic thickener, 3 parts of flexible plant fiber, 2 parts of titanium dioxide, and foaming agent 4 parts, diatomaceous earth 6 parts, ultraviolet absorber 3 parts.

[0027] In this embodiment, the board body 3 is a phenolic board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com