Preparation method of high-coercivity manganese gallium magnetic powder

A high coercive force, permanent magnet powder technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems that it is difficult to obtain high magnetic energy product and magnetic anisotropy, and achieve short milling time and high Effects of remanence and high coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: prepare high coercive force Mn according to the following specific steps 3 Ga magnetic powder:

[0020] Step 1: After weighing 99% pure Mn and 99.5% pure Ga in proportion, obtain Mn under Ar atmosphere by using suspension smelting technology 3 Ga ingot;

[0021] Step two, the Mn obtained in step one 3 The Ga ingot was annealed at 500°C for 45 minutes in an Ar atmosphere to obtain a tetragonal alloy ingot;

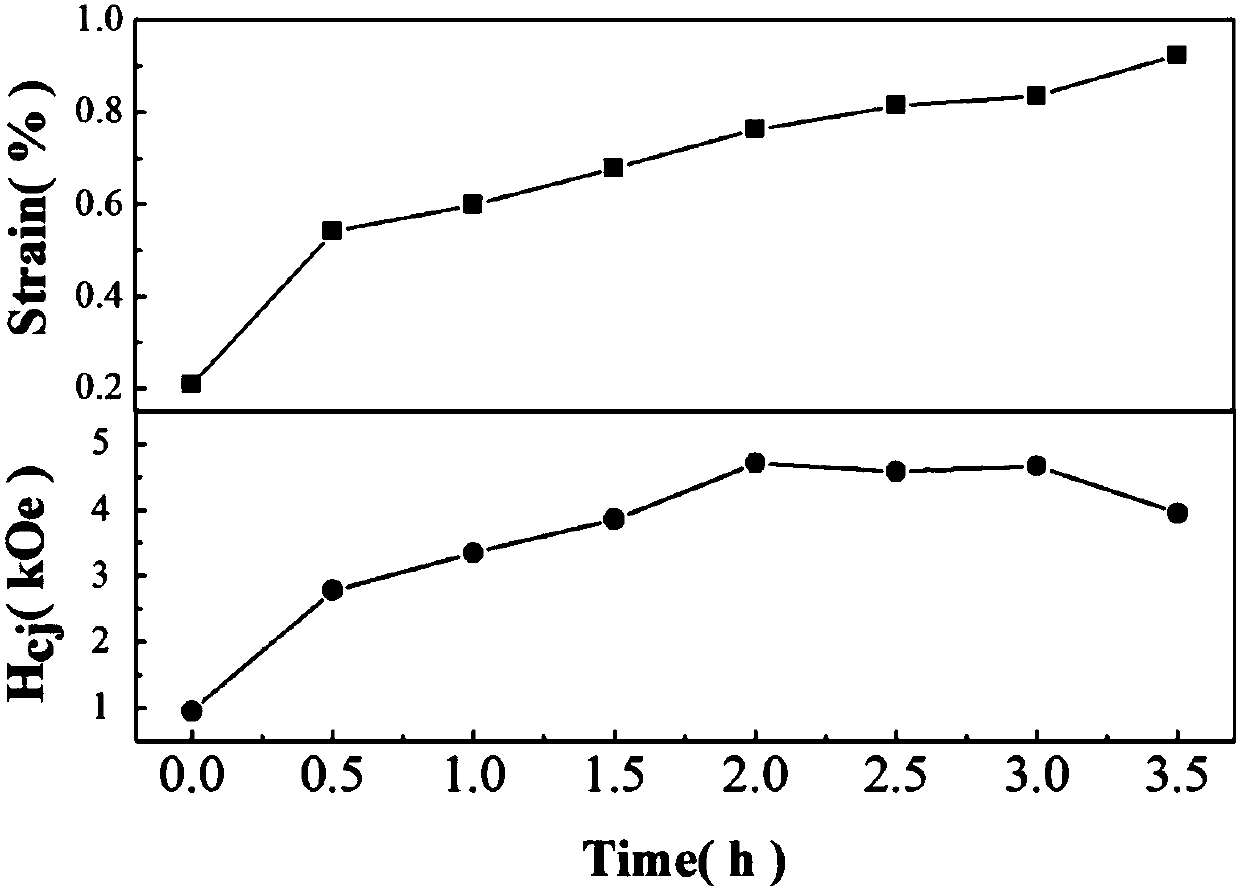

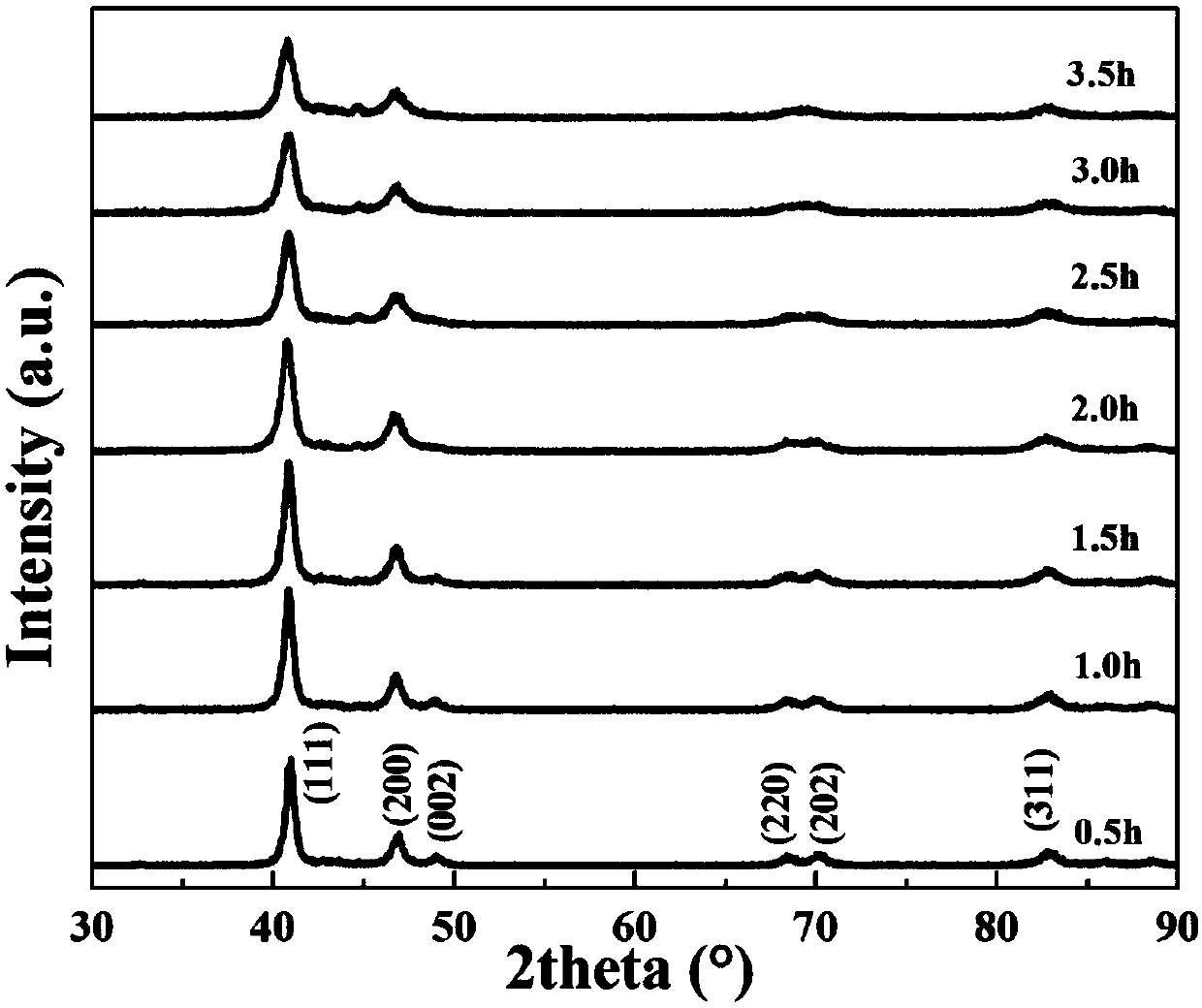

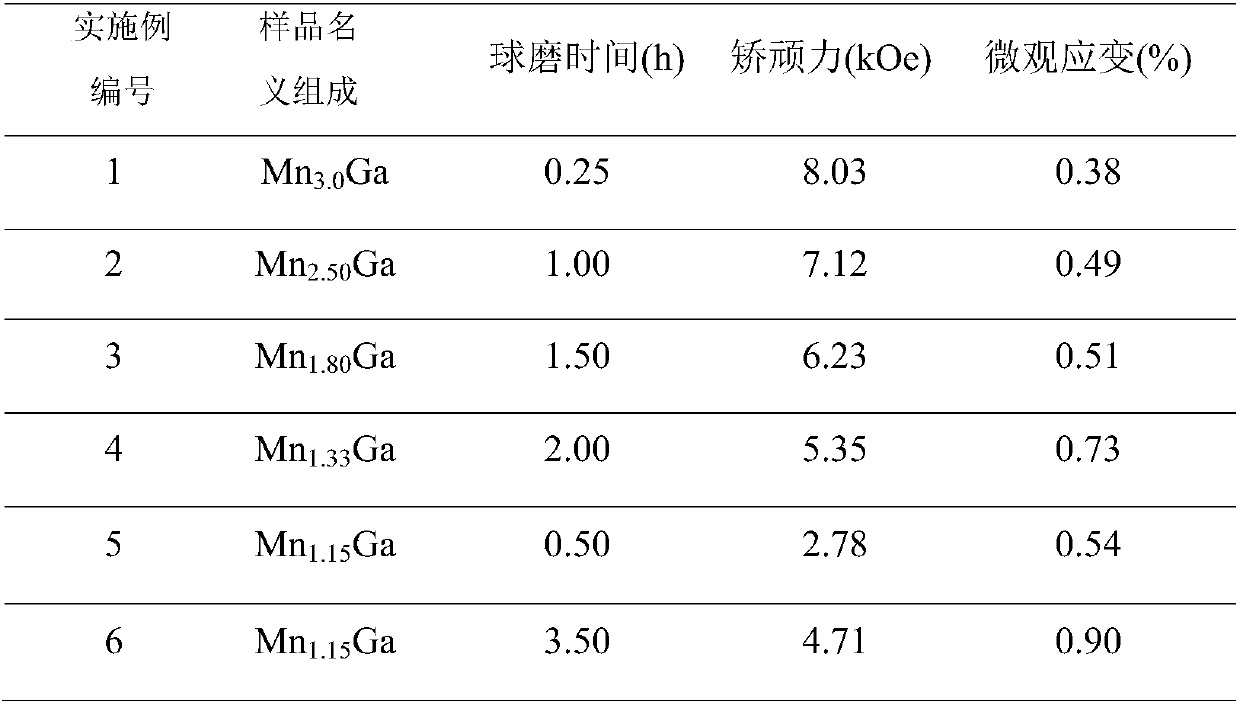

[0022] Step 3: Remove the oxide scale from the annealed ingot obtained in Step 2 and then coarsely crush it. Use a ball mill voltage of 50V, the ball-to-material ratio is 18:1 by weight, and the balls used are made of stainless steel. Three kinds of Φ10mm, the ball milling medium is 120# aviation gasoline, and the ball milling time is 0.25h. Mn after ball milling 3 The microscopic strain and coercive force of Ga magnetic powder are 0.38 and 8.03kOe, respectively.

Embodiment 2

[0023] Embodiment 2: prepare high coercive force Mn according to the following specific steps 2.50 Ga magnetic powder:

[0024] Step 1: After weighing 99% pure Mn and 99.5% pure Ga in proportion, obtain Mn under Ar atmosphere by using suspension smelting technology 2.50 Ga ingot;

[0025] Step two, the Mn obtained in step one 2.50 The Ga ingot was annealed at 500°C for 1 day in an Ar atmosphere to obtain a tetragonal alloy ingot;

[0026] Step 3: Remove the oxide skin from the annealed ingot obtained in Step 2 and then coarsely crush it. Use a ball mill voltage of 50V, the ball-to-material ratio is 20:1 by weight, and the balls used are made of stainless steel. The ball size is Φ6mm, Φ8mm, Three kinds of Φ10mm, the ball milling medium is 120# aviation gasoline, the ball milling time is 1h, the Mn after ball milling 2.50 The microscopic strain and coercive force of Ga magnetic powder are 0.49 and 7.12kOe, respectively.

Embodiment 3

[0027] Embodiment 3: prepare high coercive force Mn according to the following specific steps 1.80 Ga magnetic powder:

[0028] Step 1: After weighing 99% pure Mn and 99.9% pure Ga in proportion, obtain Mn by suspension melting technology under Ar atmosphere 1.80 Ga ingot;

[0029] Step two, the Mn obtained in step one 1.80 The Ga ingot was annealed at 610°C for 7 days in an Ar atmosphere to obtain a tetragonal alloy ingot;

[0030]Step 3: Remove the oxide skin from the annealed ingot obtained in Step 2 and then perform coarse crushing. Use a ball mill voltage of 50V, the ball-to-material ratio is 21:1 by weight, and the balls used are made of stainless steel. Three kinds of Φ10mm, the ball milling medium is 120# aviation gasoline, the ball milling time is 1.5h, the Mn after ball milling 1.80 The microscopic strain and coercive force of Ga magnetic powder are 0.51 and 6.23kOe, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com