Composite proton exchange membrane and preparation method thereof

A proton exchange membrane, mixed liquid technology, applied in fuel cells, electrochemical generators, electrical components, etc., can solve the problems of high methanol permeability, low proton conductivity, difficult preparation costs, etc. Simple, reduce the effect of descending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

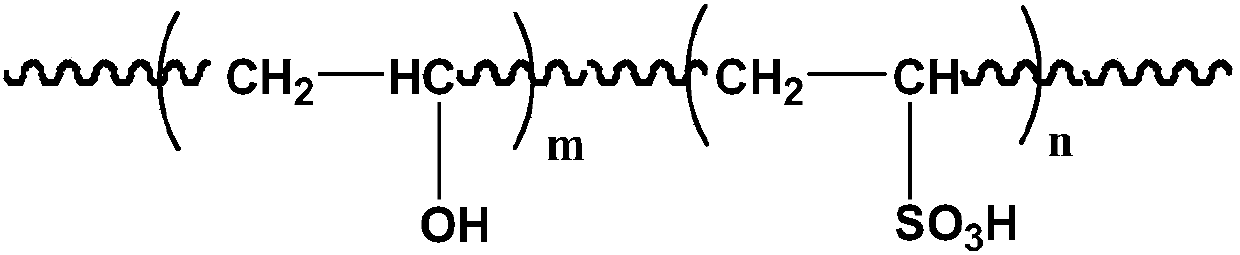

[0031] (1) Sulfonation: Add 90mL deionized water and 10g polyvinyl alcohol (PVA) into a 500mL three-neck flask, stir at 60°C for 2h, raise the temperature to 90°C and continue stirring until the PVA is completely dissolved. Afterwards, the PVA solution was placed in an ice bath to cool down, and when the temperature was cooled to 0°C, 2 mL of concentrated sulfuric acid was added dropwise to the system, and mechanically stirred for about 2 h under ice bath conditions. Then add 100mL deionized water to the system for dilution. It was then poured into 1000 mL of acetone for precipitation, washed several times, and then vacuum-dried at 40° C. for 8 h to obtain a sulfonated polyvinyl alcohol (SPVA) solid with a sulfonation degree of 10%.

[0032] (2) Preparation of yellowed polyvinyl alcohol solution: dissolving SPVA in deionized water to obtain an SPVA aqueous solution with a mass percentage of SPVA of 10%.

[0033] (3) Preparation of polyamic acid solution: Add PAA of the same q...

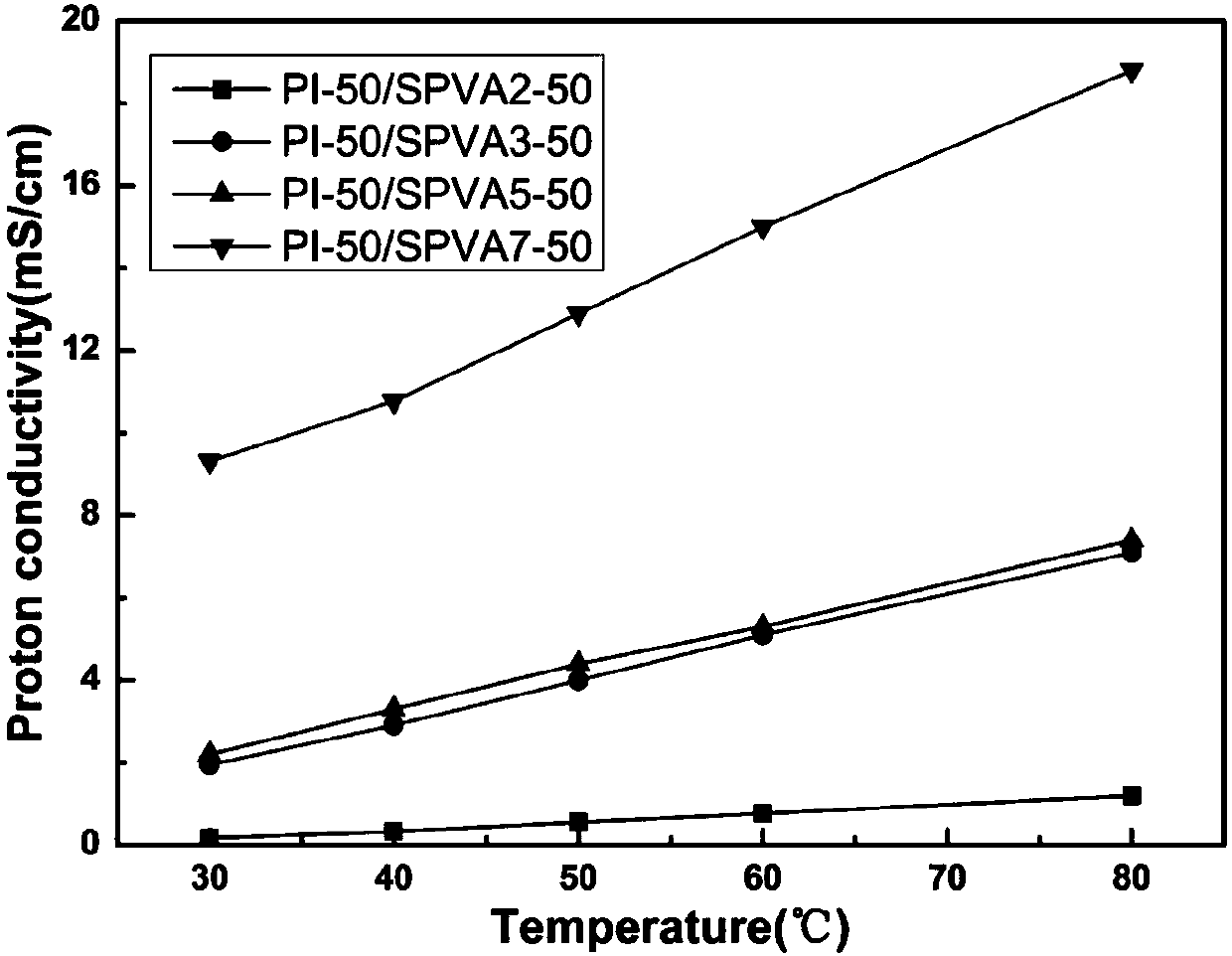

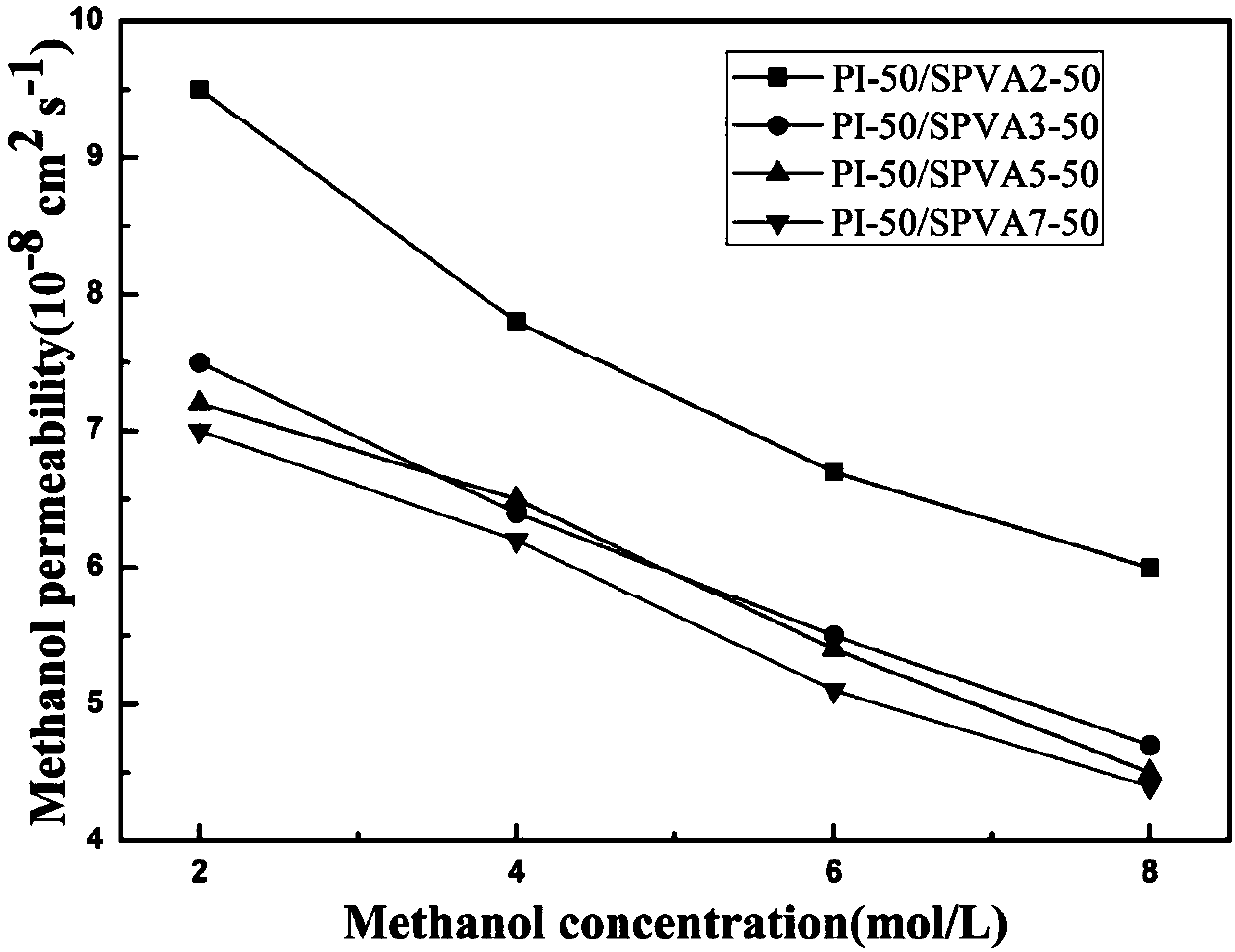

Embodiment 2

[0036] The concentrated sulfuric acid consumption that adds in the step (1) is 3mL, and all the other are with example 1. The proton conductivity of the proton exchange membrane is 7.1mS / cm, and the methanol permeability is 0.75×10 -7 cm 2 / s.

Embodiment 3

[0038] The concentrated sulfuric acid consumption that adds in the step (1) is 5mL, and all the other are with example 1. The proton conductivity of the proton exchange membrane is 7.4mS / cm, and the methanol permeability is 0.67×10 -7 cm 2 / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic conductivity | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com