A kind of preparation method of lignin-based high specific surface area carbon material

A high specific surface area, lignin-based technology, which is applied in the field of preparation of lignin-based high specific surface area carbon materials, can solve the problems of high energy consumption and environmental pollution, and achieve the goals of reducing energy consumption, avoiding environmental pollution, and increasing added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

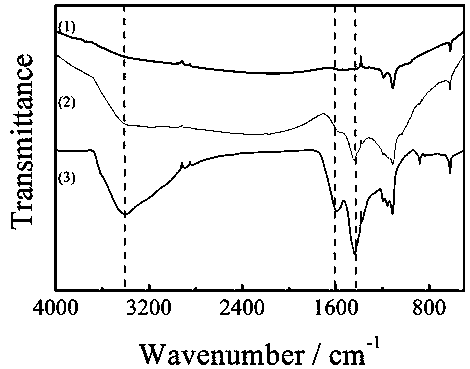

[0020] The lignin was dissolved in water to prepare a lignin aqueous solution with a concentration of 20 mg / mL. The lignin solution was quickly frozen in liquid nitrogen and freeze-dried to prepare lignin aerogels. Put the lignin airgel in a tube furnace, carbonize it in an argon atmosphere at 1000°C for 1 hour, and prepare a microscopic sheet-like carbon material after cooling, with a specific surface area of 100m 2 / g, the chemical composition is basically carbon.

Embodiment 2

[0022] Dissolve lignin in water to prepare a lignin aqueous solution with a concentration of 5 mg / mL, freeze the lignin solution at -20°C in a refrigerator, and freeze-dry to prepare lignin aerogels. Put the lignin airgel in a tube furnace, carbonize it in an argon atmosphere at 1000°C for 1 hour, and prepare a microscopic sheet-like carbon material after cooling, with a specific surface area of 205m 2 / g, the chemical composition is basically carbon.

Embodiment 3

[0024] The lignin was dissolved in water to prepare a lignin aqueous solution with a concentration of 1 mg / mL, and the lignin solution was quickly frozen in liquid nitrogen and freeze-dried to prepare lignin aerogels. The lignin airgel was placed in a tube furnace and carbonized in an argon atmosphere at 1000 °C for 1 hour. After cooling, a carbon material with a microscopic fiber structure was prepared. The specific surface area of the product was 705 m 2 / g, the chemical composition is basically carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com