Ultra-high temperature-resistant water-based drilling fluid

A water-based drilling fluid and ultra-high temperature technology, applied in the field of drilling fluid, can solve the problems of poor stability of high-temperature drilling fluid and weakened comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

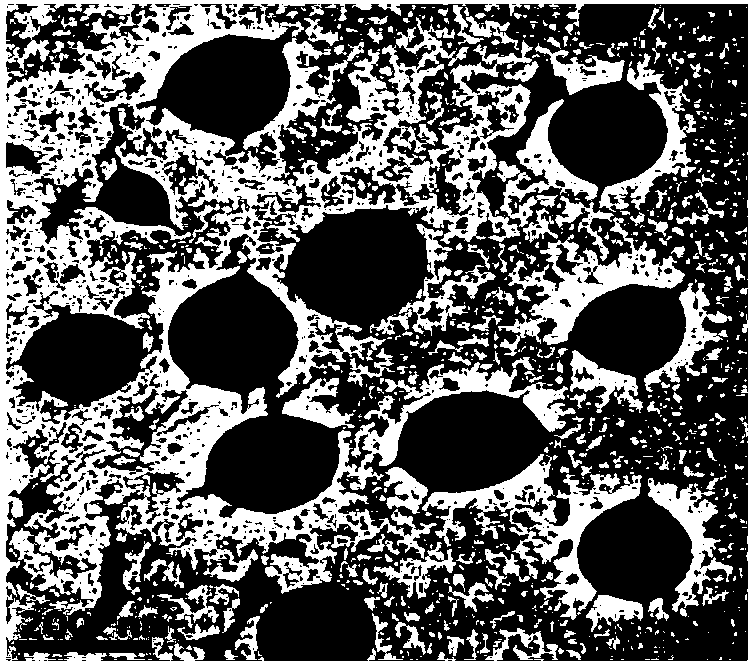

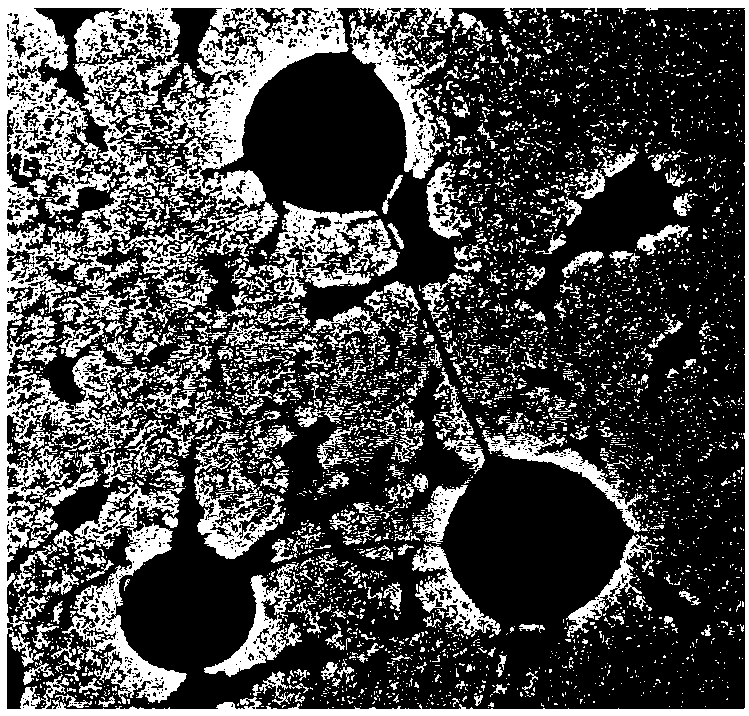

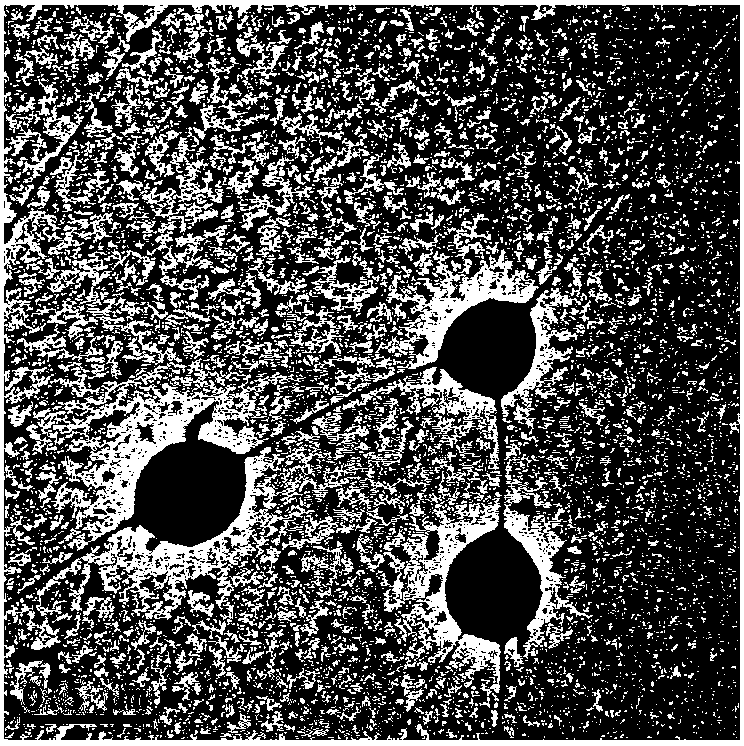

Image

Examples

preparation example Construction

[0053] In the present invention, the preparation method of the rheological stabilizer preferably comprises the following steps:

[0054] The oil phase and the water phase are mixed and subjected to primary heat treatment to obtain an oil-water mixture;

[0055] mixing the oil-water mixture and the initiator for secondary heat treatment to obtain a mixture including the initiator;

[0056] The mixture including the initiator and the crosslinking agent are mixed to carry out a polymerization reaction to obtain a rheological stabilizer.

[0057] In the invention, the oil phase and the water phase are mixed and subjected to primary heat treatment to obtain the oil-water mixture. In the present invention, the temperature of the primary heat treatment is preferably 40-50°C, more preferably 42-48°C, most preferably 44-46°C; the time of the primary heat treatment is preferably 1-3 hours , specifically can be 1 hour, 2 hours or 3 hours. In the present invention, the first-stage heat...

Embodiment 1

[0071] Mix 12.5 g of Span 80, 10 g of oleic acid diethanolamide and 2.5 g of fumed silicon dioxide to obtain an emulsifier, and mix 500 g of white oil and 25 g of the emulsifier to obtain an oil phase.

[0072] 196.875 g of 2-acrylamido-2-methylpropanesulfonic acid, 262.5 g of N,N-diethylacrylamide, 131.25 g of methacrylic acid and 65.625 g of acrylamide were mixed to obtain an aqueous phase.

[0073] 32.8125 g of ammonium persulfate and 32.8125 g of sodium persulfate were mixed to obtain an initiator.

[0074] Weigh 65.625 g of diacetone acrylamide as a crosslinking agent.

[0075] Mix the oil phase and the water phase, heat treatment at 40°C for 1.5 hours to obtain an oil-water mixture;

[0076] mixing the oil-water mixture and the initiator, and heating at 60°C for 2 hours to obtain a mixture including the initiator;

[0077] The mixture including the initiator and the crosslinking agent were mixed, and polymerized at 50° C. for 5 hours to obtain a rheological stabilizer....

Embodiment 2

[0079] Mix 8 g of Span 80 and 12 g of oleic acid diethanolamide to obtain an emulsifier, and mix 500 g of white oil and 20 g of the emulsifier to obtain an oil phase.

[0080] 148.56 g of 2-acrylamido-2-methylpropanesulfonic acid, 148.56 g of N,N-diethylacrylamide, 148.56 g of methacrylic acid, and 148.56 g of acrylamide were mixed to obtain an aqueous phase.

[0081] Weigh 18.57g of benzoyl peroxide as initiator.

[0082] 9.29 g of methylenebisacrylamide and 9.29 g of N-hydroxyethylacrylamide were mixed to obtain a crosslinking agent.

[0083] Mix the oil phase and the water phase, heat treatment at 40°C for 1.5 hours to obtain an oil-water mixture;

[0084] mixing the oil-water mixture and the initiator, and heating at 80°C for 2 hours to obtain a mixture including the initiator;

[0085] The mixture including the initiator and the crosslinking agent were mixed, and polymerized at 50° C. for 5 hours to obtain a rheological stabilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com