Method for improving purity of vancomycin hydrochloride through ion exchange resin

The technology of vancomycin hydrochloride and ion exchange resin is applied in the field of improving the purity of vancomycin hydrochloride by using ion exchange resin, which can solve the problems of difficult large-scale application, complicated process and low purity, and achieves large processing capacity and simple production process. , the effect of the simple regeneration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

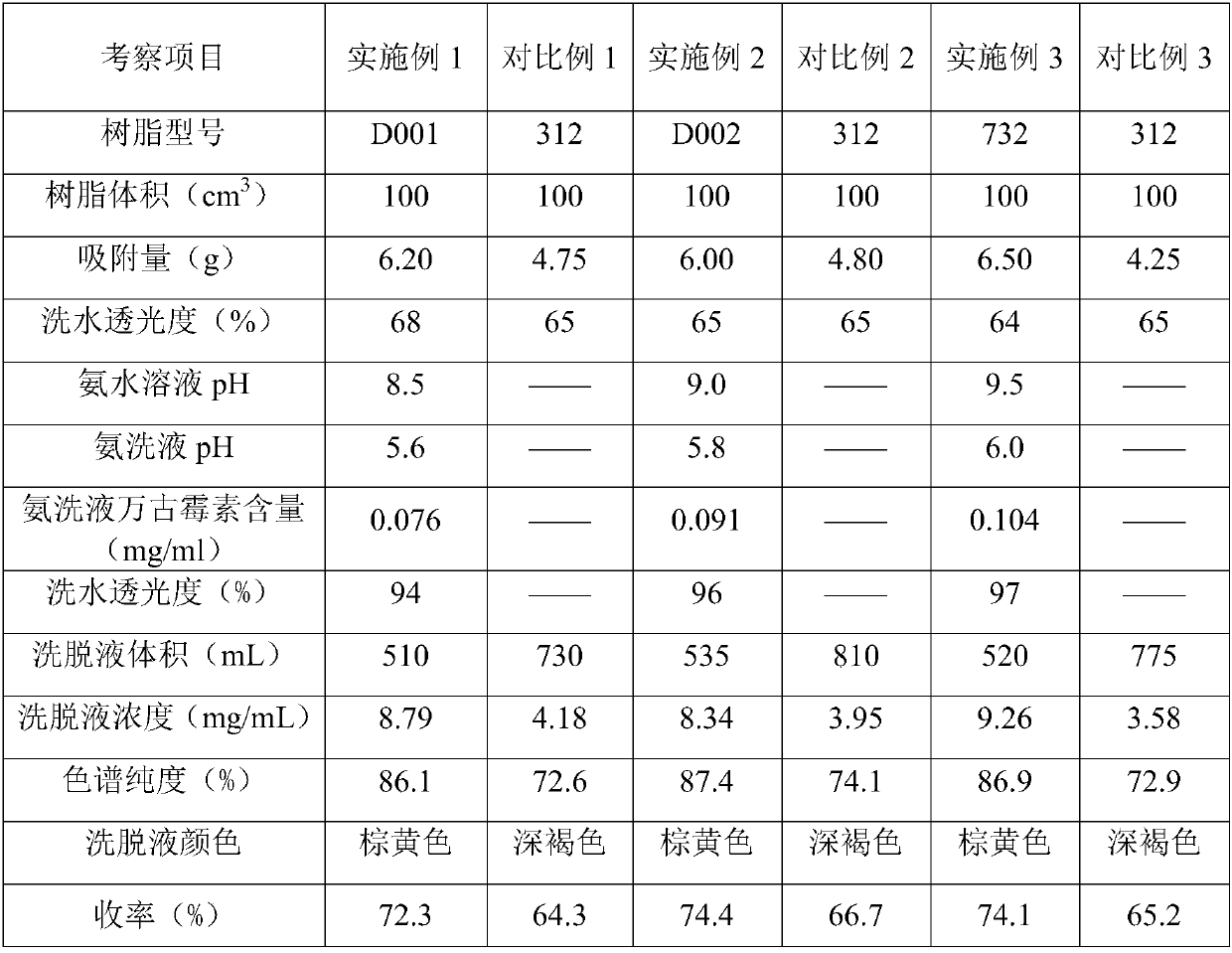

Embodiment 1

[0020] The selected macroporous strongly acidic cation exchange resin is D001, and the volume of the resin is 100cm 3 , first ensure that the resin is converted into a strong acid salt, and then pass the filtered vancomycin fermentation broth into the resin tank for adsorption. The vancomycin content in the fermentation broth is 3.2mg / mL. When the export unit of the resin tank reaches more than 90% of the import unit, it is determined that the main tank is saturated. When the adsorption is saturated, the resin is washed with deionized water until the outlet water sample is clear, and then backwashed until the transmittance of the resin outlet water sample is 68%. Prepare an ammonia solution with a pH of 8.5 in the alkali cleaning circulation tank, and pass it through the resin column for circular washing. When the pH of the solution in the circulating tank is 5.6, backwash with deionized water until the water sample transmittance at the resin outlet 94%. Then use 3 mol / L amm...

Embodiment 2

[0022] The selected macroporous strongly acidic cation exchange resin is D002, and the resin volume is 100cm 3 , first ensure that the resin is converted into a strong acid salt, and then pass the filtered vancomycin fermentation broth into the resin tank for adsorption. The vancomycin content in the fermentation broth is 3.2mg / mL. When the export unit of the resin tank reaches more than 90% of the import unit, it is determined that the main tank is saturated. When the adsorption is saturated, the resin is positively washed with deionized water until the outlet water sample is clear, and then backwashed until the light transmittance of the resin outlet water sample is 65%. Prepare an ammonia solution with a pH of 9.0 in the alkali cleaning circulation tank, and pass it through the resin column for circular washing. When the pH of the solution in the circulating tank is 5.8, backwash with deionized water until the water sample at the resin outlet is transparent. 96%. Then use...

Embodiment 3

[0024] The selected macroporous strongly acidic cation exchange resin is 732, and the resin volume is 100cm 3 , first ensure that the resin is converted into a strong acid salt, and then pass the filtered vancomycin fermentation broth into the resin tank for adsorption. The vancomycin content in the fermentation broth is 3.2mg / mL. When the export unit of the resin tank reaches more than 90% of the import unit, it is determined that the main tank is saturated. When the adsorption is saturated, the resin is positively washed with deionized water until the outlet water sample is clear, and then backwashed until the light transmittance of the resin outlet water sample is 64%. Prepare an ammonia solution with a pH of 9.5 in the alkali cleaning circulation tank, and pass it through the resin column for circular washing. When the pH of the solution in the circulating tank is 6.0, backwash with deionized water until the water sample at the resin outlet is transparent. 97%. Then use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com