Natural gas foam stabilizer system and preparation method thereof

A technology of foam stabilizer and natural gas, which is applied in the field of natural gas foam stabilizer system and its preparation, and can solve the problems of few reports on the stability of natural gas foam system, the reduction of foam volume and stability, and the weakening of nano-SiO adsorption, etc. problem, to avoid poor anti-rock adsorption ability, good foam stability, and good foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A natural gas foam stabilizer system composed of the following components by mass percentage: nano SiO 2 The particle dispersion is 22.7%, the fatty alcohol polyoxyethylene ether sodium sulfate with an EO number of 3 0.006%, the rest is mineralized water, the mineralized water is made of NaCl, and the total salinity is 100000mg·L -1 .

[0032] The preparation method is as follows: NaCl is added to water and stirred uniformly at room temperature to prepare mineralized water, and 0.1g of fatty alcohol polyoxyethylene ether sodium sulfate with EO number of 3 is dissolved in 1665.9g of mineralized water and stirred evenly to obtain 0.006% EO number 3 fatty alcohol polyoxyethylene ether sodium sulfate aqueous solution, take 15.46g from it, and gradually add 4.54g nano SiO 2 The particle dispersion is evenly mixed to obtain a natural gas foam stabilizer system suitable for high temperature and high salt environments.

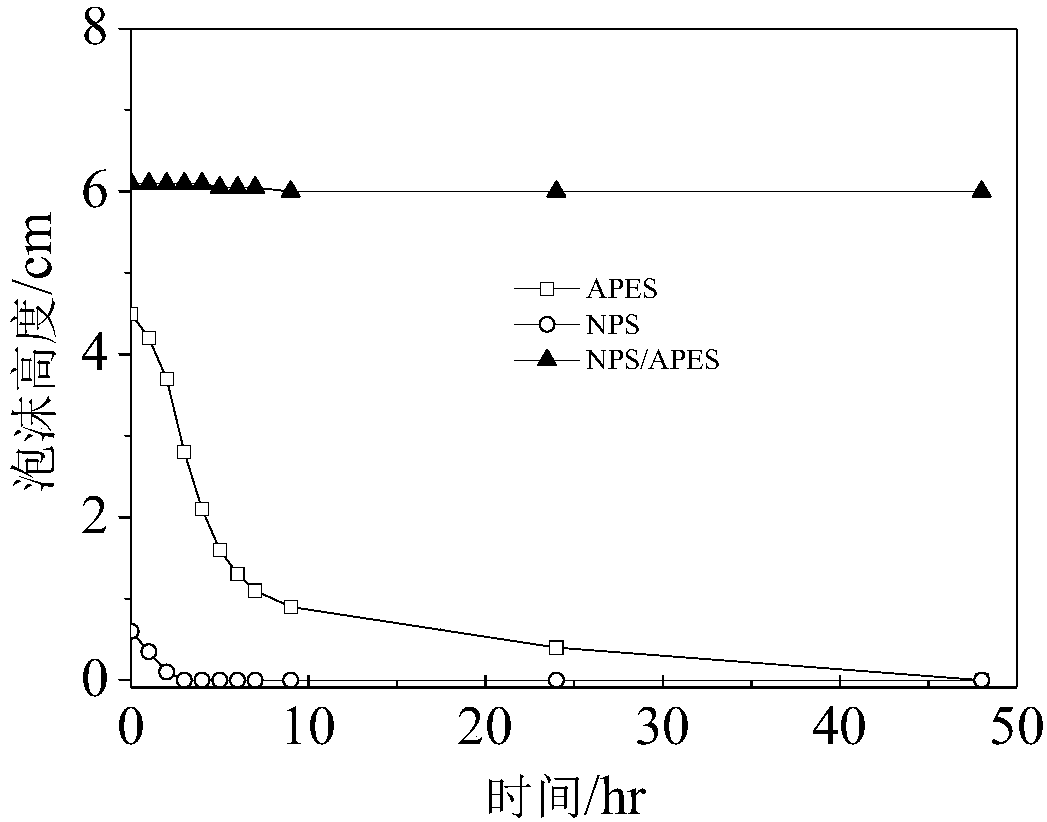

[0033] Foam property evaluation test, such as figure 1 As shown...

Embodiment 2

[0035] A natural gas foam stabilizer system composed of the following components by mass percentage: nano SiO 2 The particle dispersion is 22.7%, the fatty alcohol polyoxyethylene ether sodium sulfate with an EO number of 3 is 0.006%, and the rest is mineralized water, which is composed of CaCl 2 It is formulated with a total salinity of 100000mg·L -1 .

[0036] The preparation method is as follows: CaCl 2 Add into water and stir evenly to prepare mineralized water, take 0.1g of fatty alcohol polyoxyethylene ether sodium sulfate with EO number of 3, dissolve in 1665.9g of mineralized water, stir evenly to obtain 0.006% of fatty alcohol polyoxyethylene with EO number of 3 Ether sodium sulfate aqueous solution, take 15.46g from it, gradually add 4.54g nano SiO 2 The particle dispersion is evenly mixed to obtain a natural gas foam stabilizer system suitable for high temperature and high salt environments.

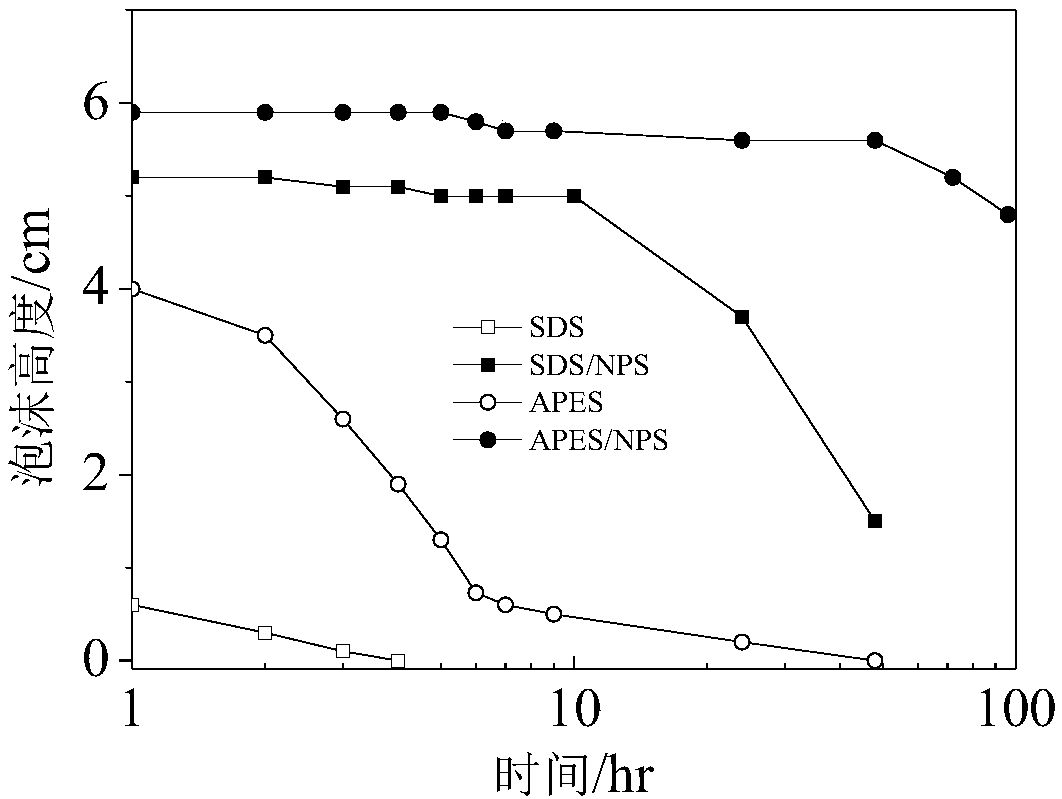

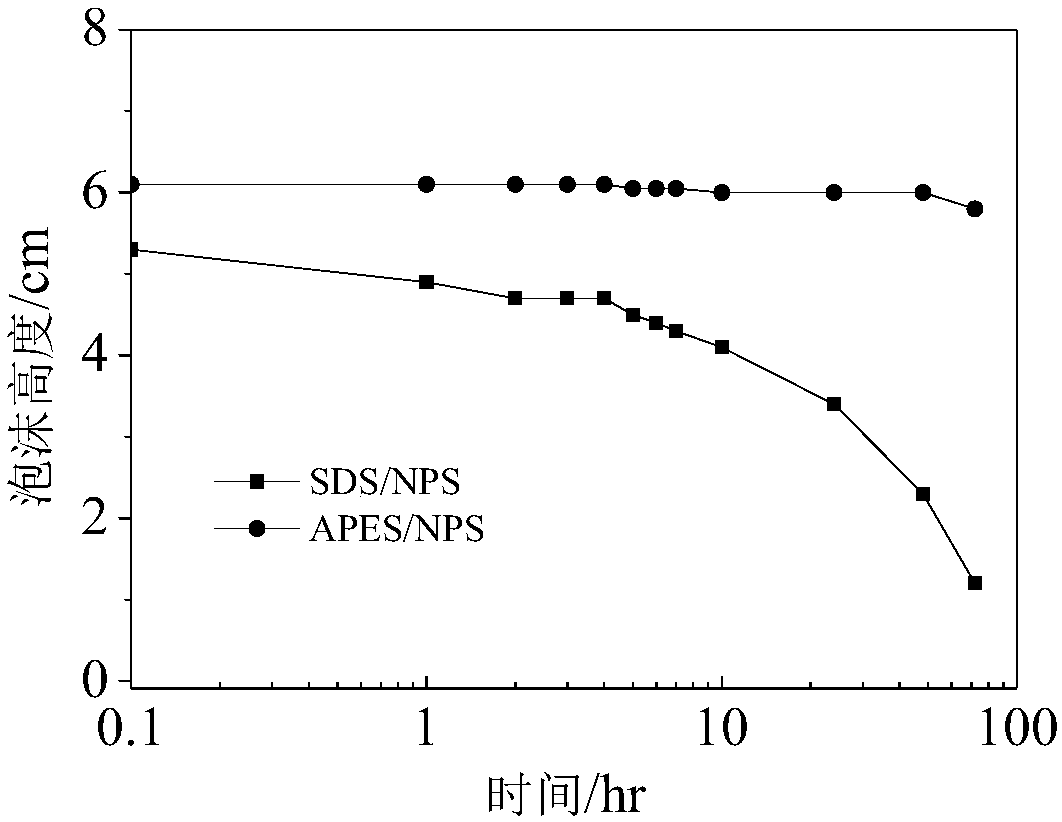

[0037] Foam property evaluation test, in CaCl 2 Prepared 100000mg·L -1 In the m...

Embodiment 3

[0039] A natural gas foam stabilizer system composed of the following components by mass percentage: nano SiO 2 The particle dispersion is 56.8%, the fatty alcohol polyoxyethylene ether sodium sulfate with an EO number of 3 is 0.012%, and the rest is mineralized water. The mineralized water is prepared from NaCl, with a total salinity of 100000 mg.L -1 .

[0040] The preparation method is as follows: NaCl is added to water and stirred uniformly at room temperature to prepare mineralized water, and 0.2g of fatty alcohol polyoxyethylene ether sodium sulfate with EO number of 3 is dissolved in 1665.8g of mineralized water and stirred evenly to obtain 0.012% EO. 3 fatty alcohol polyoxyethylene ether sodium sulfate aqueous solution, take 8.64g from it, and gradually add 11.36g nano-SiO 2 The particle dispersion is evenly mixed to obtain a natural gas foam stabilizer system suitable for high temperature and high salt environments.

[0041] Foam property evaluation test, 100000mg·L prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com