Schiff base derivative and preparation method thereof

A technology for Schiff bases and derivatives, applied in the field of Schiff base derivatives and their preparation, can solve the problems of using organic solvents for Schiff base derivatives, and achieve easy availability of equipment and raw materials, easy operation and control, and solubility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

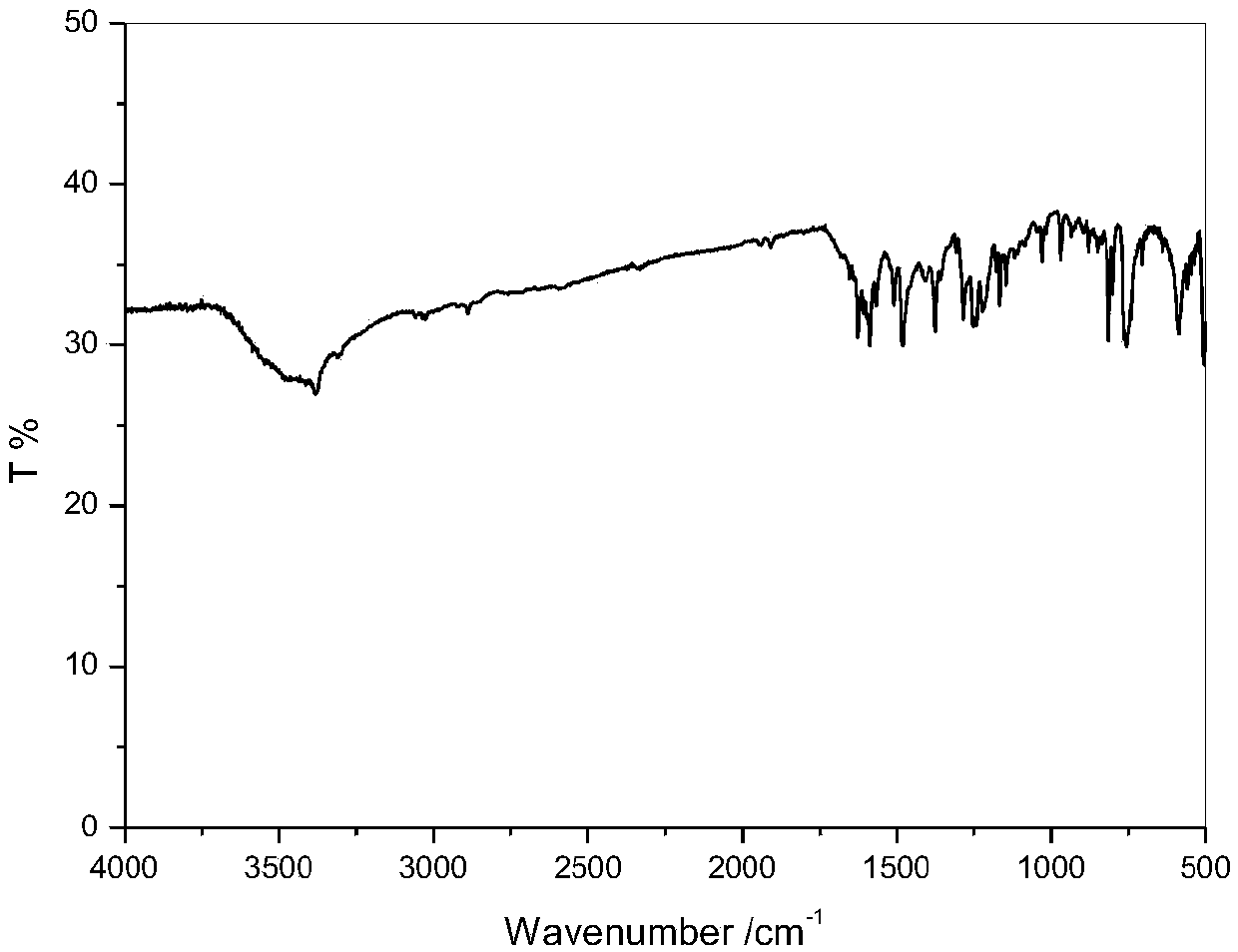

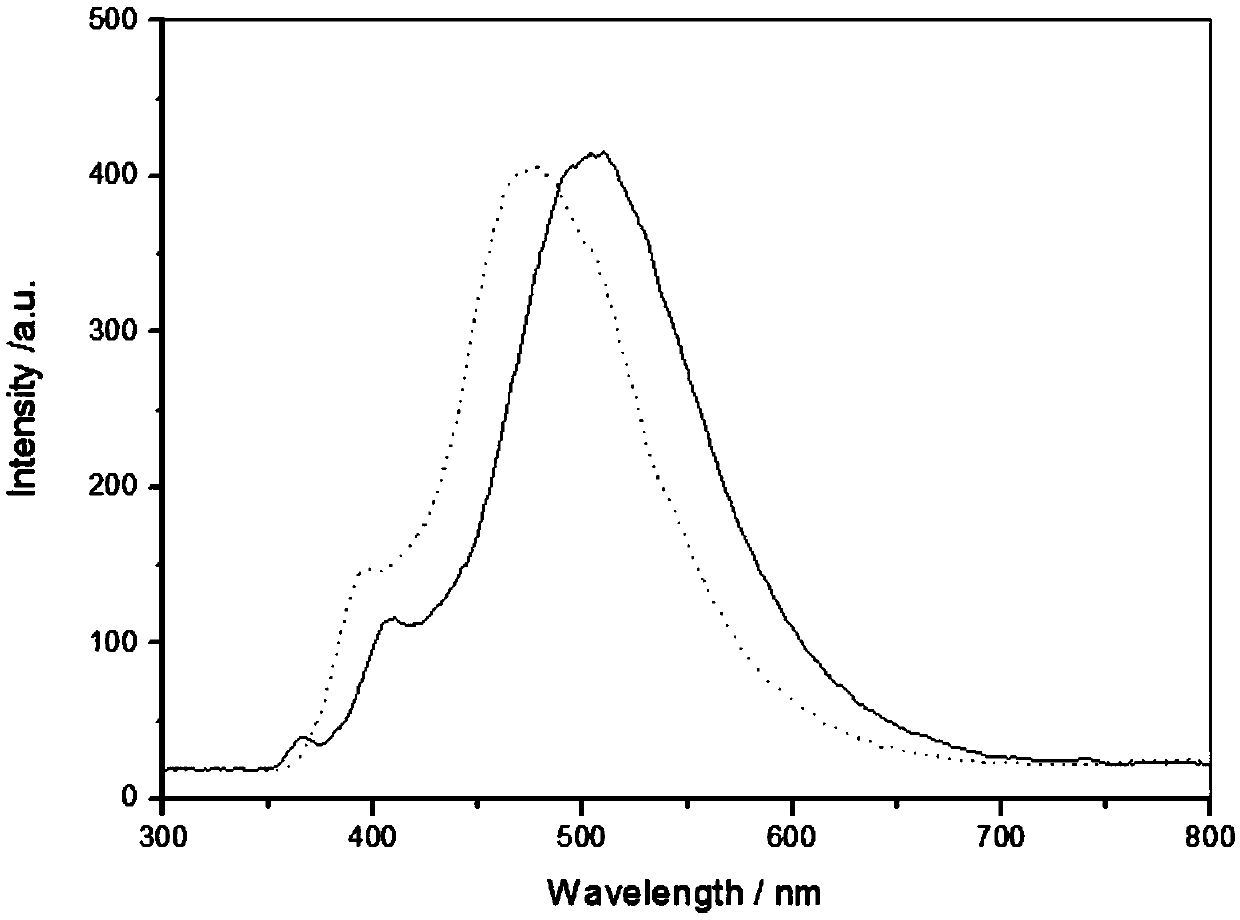

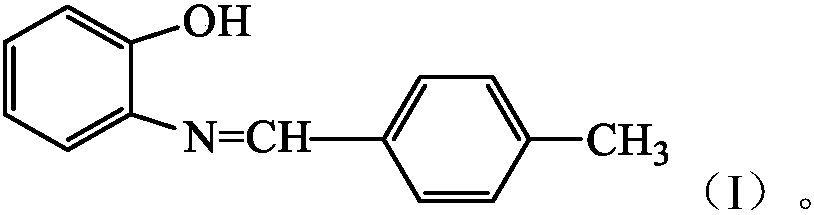

[0027] In a 25mL hydrothermal reactor, add 15mL of water (filling degree is 60%), then add 1mmol of o-aminophenol and 1mmol of p-tolualdehyde, and react at 150°C for 180 minutes. After the reaction, the reactor was cooled to room temperature, and the reaction product was filtered, dried, recrystallized, and dried in sequence to obtain the target product. The solvent used for recrystallization in this example was ethyl acetate.

Embodiment 2

[0029] In a 50 mL hydrothermal reaction kettle, add 25 mL of water (filling degree is 50%), then add 2 mmol of o-aminophenol and 2 mmol of p-tolualdehyde, and react at 120° C. for 240 minutes. After the reaction, the reactor was cooled to room temperature, and the reaction product was filtered, dried, recrystallized, and dried in sequence to obtain the target product. The solvent used for recrystallization in this example was 95% ethanol.

Embodiment 3

[0031] In a 50 mL hydrothermal reactor, add 20 mL of water (filling degree is 40%), then add 1 mmol of o-aminophenol and 1.5 mmol of p-tolualdehyde, and react at 100° C. for 300 minutes. After the reaction, the reactor was cooled to room temperature, and the reaction product was filtered, dried, recrystallized, and dried in sequence to obtain the target product. The solvent used for recrystallization in this example was ethyl acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com