High-performance structural adhesive for reinforcement project with water environment and preparation method of high-performance structural adhesive

A high-performance, adhesive technology, applied in the field of chemical building materials, can solve the problems that cannot meet the application requirements of hydraulic building reinforcement engineering, poor bonding performance of structural adhesives, etc., to reduce adverse effects, improve hydrophobicity, and good toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

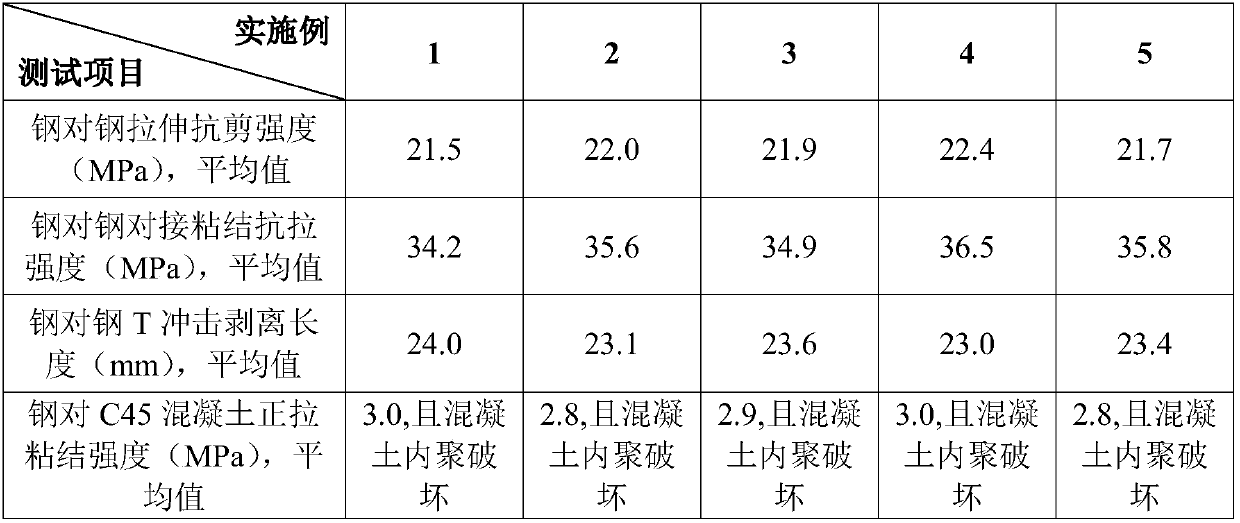

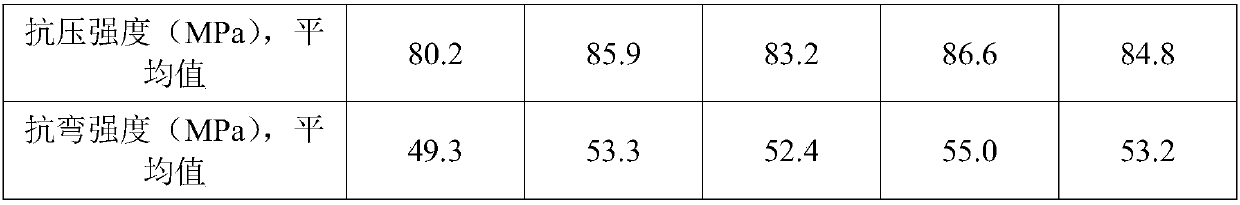

Embodiment 1

[0035] The high-performance structural adhesive for water environment reinforcement engineering is composed of A and B components, and the mass ratio is A component: B component = 2:1. After the components A and B are accurately weighed according to the mass ratio, they are stirred and mixed evenly to obtain the present invention.

[0036] The formula of the A component in parts by mass is: 60 parts of nano-silica graft modified epoxy resin, 10 parts of epoxy reactive diluent, 30 parts of elastic modifier, 1 part of water-absorbing resin, defoaming resin 0.1 part of dispersant, 0.1 part of dispersant, 120 parts of active silica powder, 5 parts of cement, 5 parts of calcium sulfate whiskers, 3 parts of organic montmorillonite, 4 parts of thixotropic agent;

[0037] The formula of the B component in parts by mass is: 30 parts of phenalkamine curing agent, 70 parts of polyamide curing agent, 4 parts of curing accelerator, 4 parts of coupling agent; 0.1 part of defoamer, 0.1 part ...

Embodiment 2

[0043] The high-performance structural adhesive for water environment reinforcement engineering is composed of two components, A and B, and the mass ratio is component A: component B = 3:1; after weighing components A and B accurately according to the mass ratio, Stir and mix evenly to obtain the present invention.

[0044] The formula of the A component in terms of parts by mass is: 80 parts of nano-silica grafted modified epoxy resin, 0 parts of epoxy active diluent, 10 parts of elastic modifier, 2 parts of water-absorbing resin, defoaming resin 0.2 parts of dispersant, 0.2 parts of dispersant, 180 parts of active silica powder, 10 parts of cement, 15 parts of calcium sulfate whiskers, 8 parts of organic montmorillonite, and 1 part of thixotropic agent;

[0045] The formula of the B component in parts by mass is: 70 parts of phenalkamine curing agent, 30 parts of polyamide curing agent, 0 part of curing accelerator, 7 parts of coupling agent; 0.2 parts of defoaming agent, 0....

Embodiment 3

[0051] The high-performance structural adhesive for water environment reinforcement engineering is composed of two components, A and B, and the mass ratio is component A: component B = 3:1; after weighing components A and B accurately according to the mass ratio, Stir and mix evenly to obtain the present invention.

[0052] The formula of the A component in parts by mass is: 70 parts of nano-silica grafted modified epoxy resin, 5 parts of epoxy reactive diluent, 20 parts of elastic modifier, 1.5 parts of water-absorbing resin, defoaming resin 0.15 parts of agent, 0.15 parts of dispersant, 150 parts of active silica powder, 8 parts of cement, 10 parts of calcium sulfate whiskers, 5 parts of organic montmorillonite, 2 parts of thixotropic agent;

[0053] The formula of the B component in parts by mass is: 50 parts of phenalkamine curing agent, 50 parts of polyamide curing agent, 3 parts of curing accelerator, 5 parts of coupling agent; 0.15 parts of defoaming agent, 0.15 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com