Self-powered sensor for monitoring flow rate of pipeline flow based on vortex-induced vibration

A technology of vortex-induced vibration and pipeline flow, which is applied in the direction of fluid velocity measurement, velocity/acceleration/shock measurement, instruments, etc. It can solve the problems of promotion and application limitations, limited service life, unfavorable miniaturization, etc., and achieve strong compatibility and scalability , no electromagnetic interference, the structure can be miniaturized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

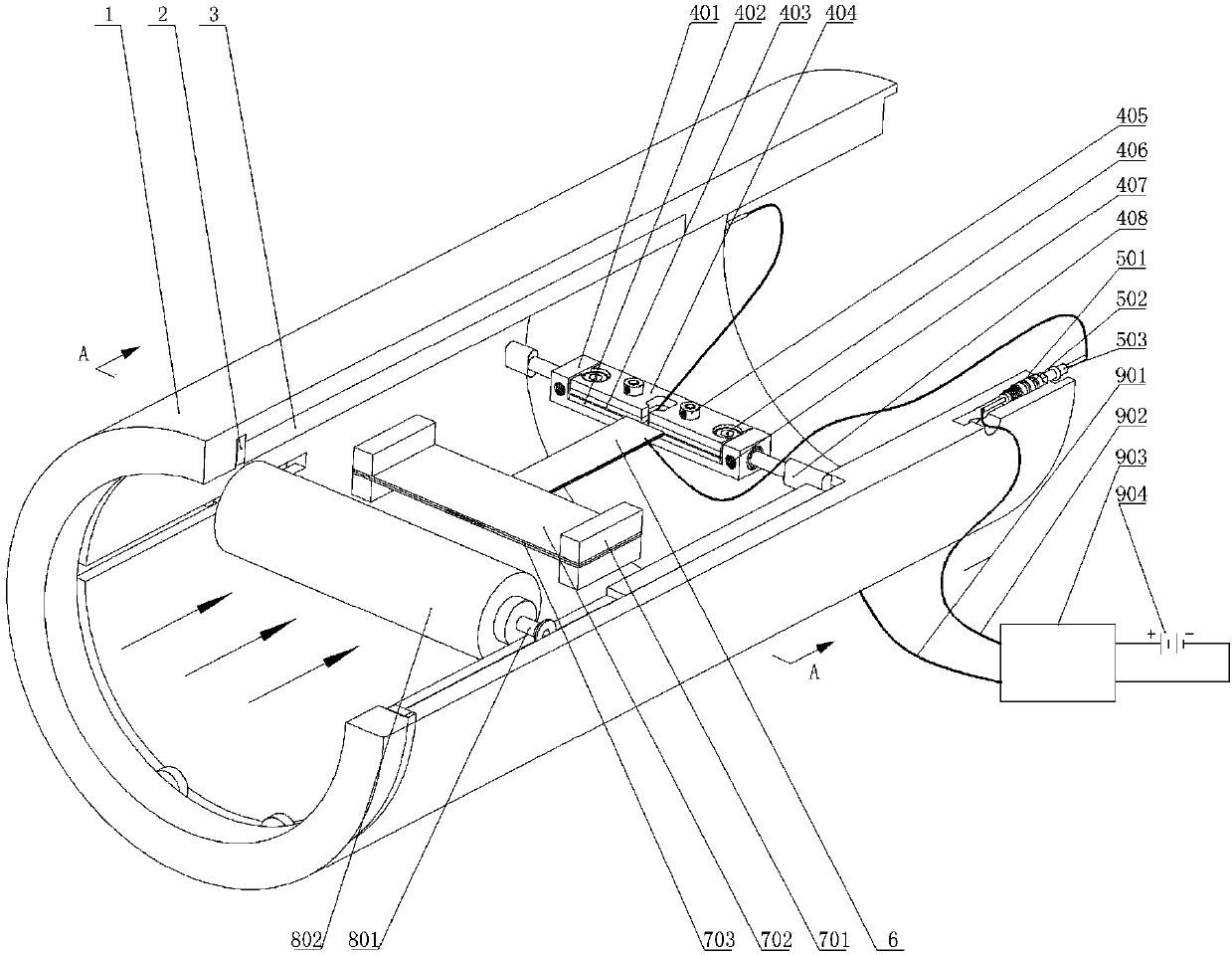

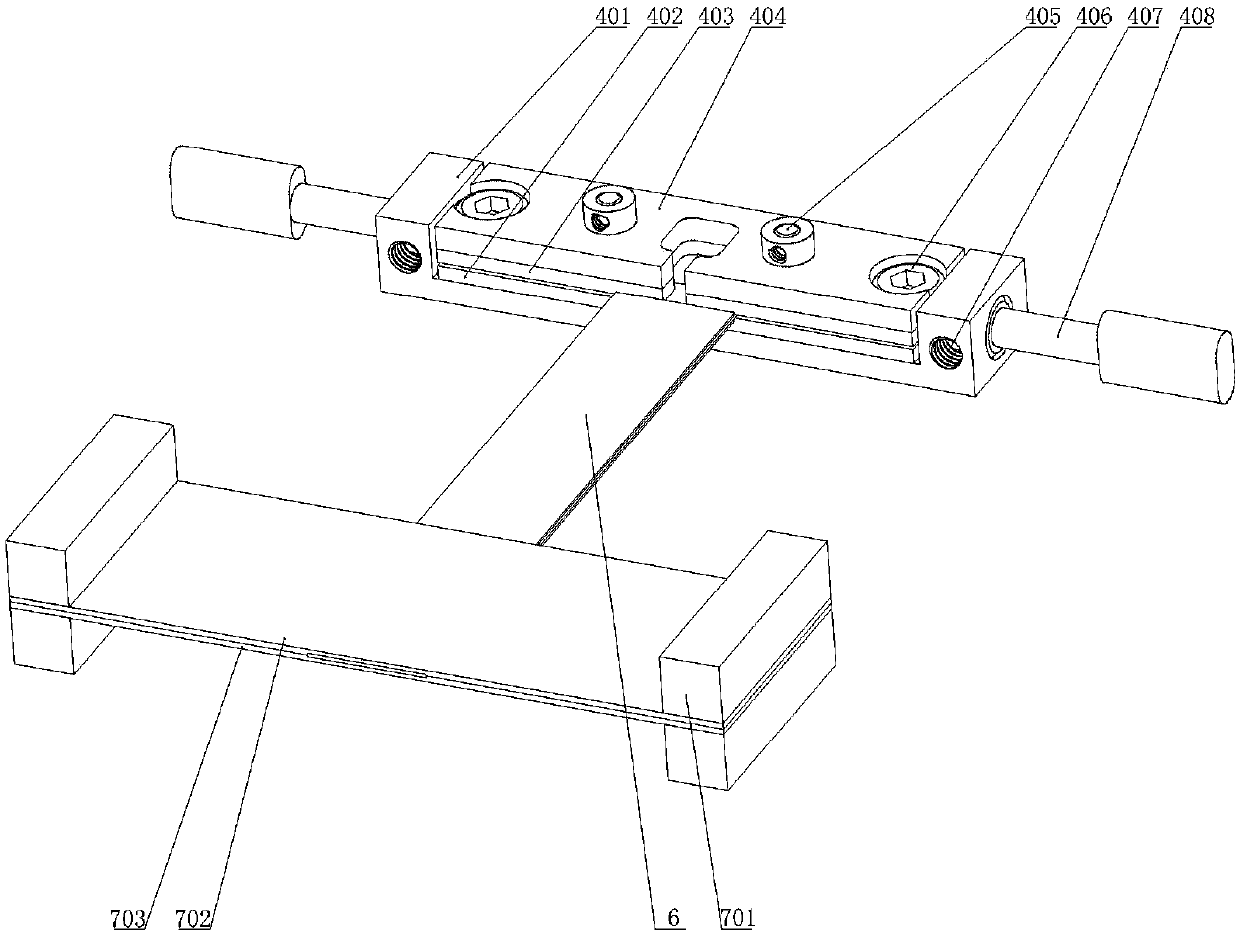

[0042] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

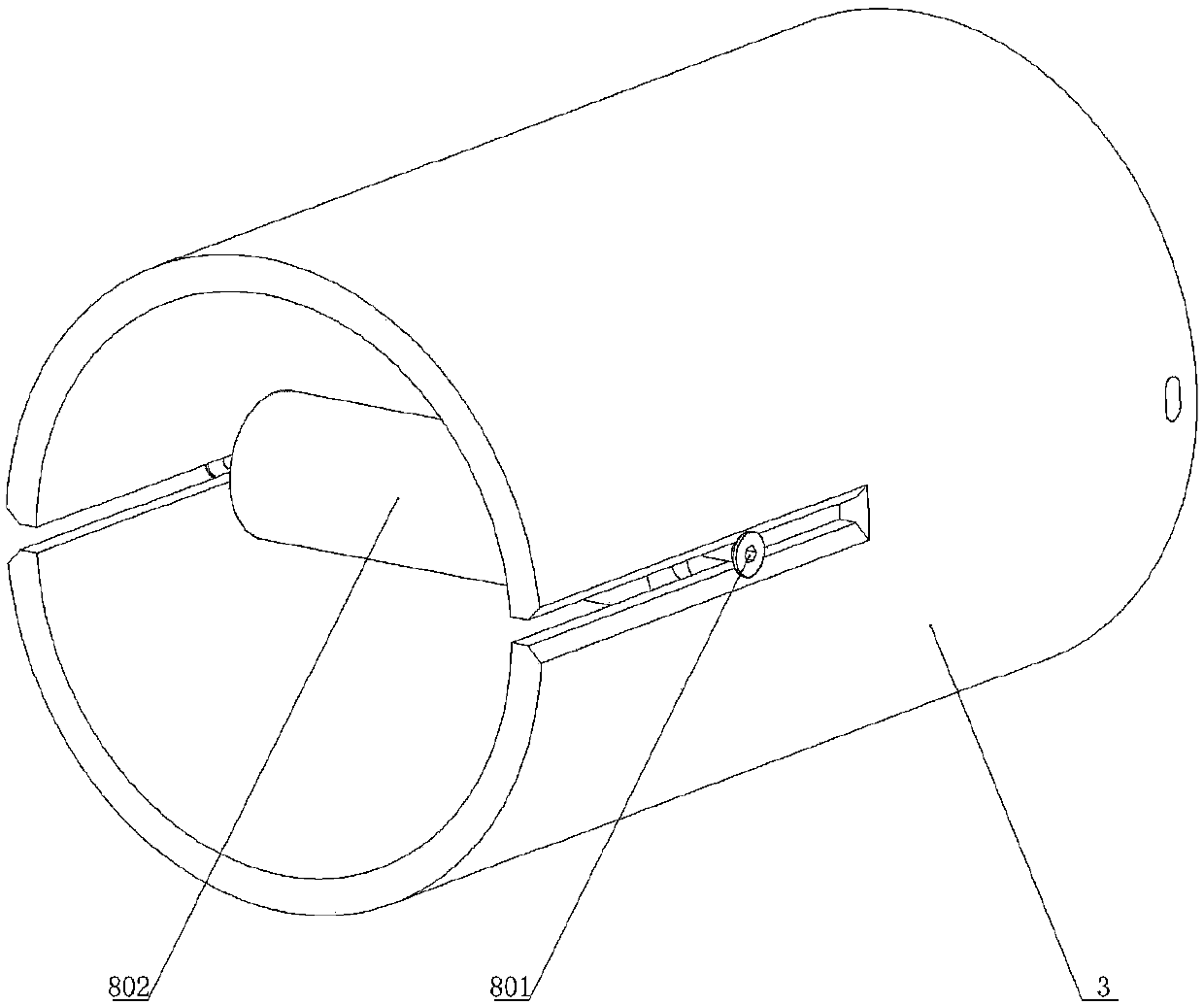

[0043] like figure 1 As shown, one side of the outer cylinder 1 has a stepped hole and a round hole inner groove for installing the circlip 2 for the hole, and the other side has an axial stepped hole for installing the lead wire sealing plug 503 inside the cylinder wall and Radial connection holes; the main body of the lead wire sealing plug 503 is made of conductive copper material, and is axially installed in the axial stepped hole of the outer cylinder 1 through threaded fit, the first sealing ring 501 and the second sealing ring 502 on the lead wire sealing plug 503 The inner surface of the stepped hole forms a static seal; the lead wire sealing plugs 503 are symmetrically arranged in the inner wall of the outer cylinder 1, and the conductive copper needles at one end of the two lead wire sealing plugs 503 are respectively connected to the positive and negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com