Probiotics solid beverage and preparation method thereof

A solid beverage and probiotic technology, which is applied to bacteria, lactobacillus, bifidobacteria and other directions used in food preparation, can solve the problems of inconvenient carrying of liquid beverages, inability to supplement nutrition, and inability to improve immunity well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In a specific embodiment, the preparation method of the fruit and vegetable enzyme powder comprises: crushing and mixing the raw materials of the fruit and vegetable enzyme powder, adding brown sugar and lactic acid bacteria whose weight is 80% to 100% of the total mass of the fruit and vegetable enzyme powder raw materials, and fermenting at 20°C to 30°C After 10 to 30 days, through infiltration, sedimentation and filtration, the primary fermented fruit and vegetable enzyme stock solution is obtained; the primary fermented fruit and vegetable enzyme stock solution is fermented at 20°C to 30°C for 5 to 7 months, then concentrated at low temperature and freeze-dried to obtain Fruit and vegetable enzyme powder. Calculated based on the volume of fermented liquid, the amount of lactic acid bacteria added is 1×10 7 ~1.5×10 7 CFU / ml.

[0024] In a specific embodiment, the probiotics include Bifidobacterium longum, Bifidobacterium breve, Lactobacillus plantarum, Lactobacillu...

Embodiment 1

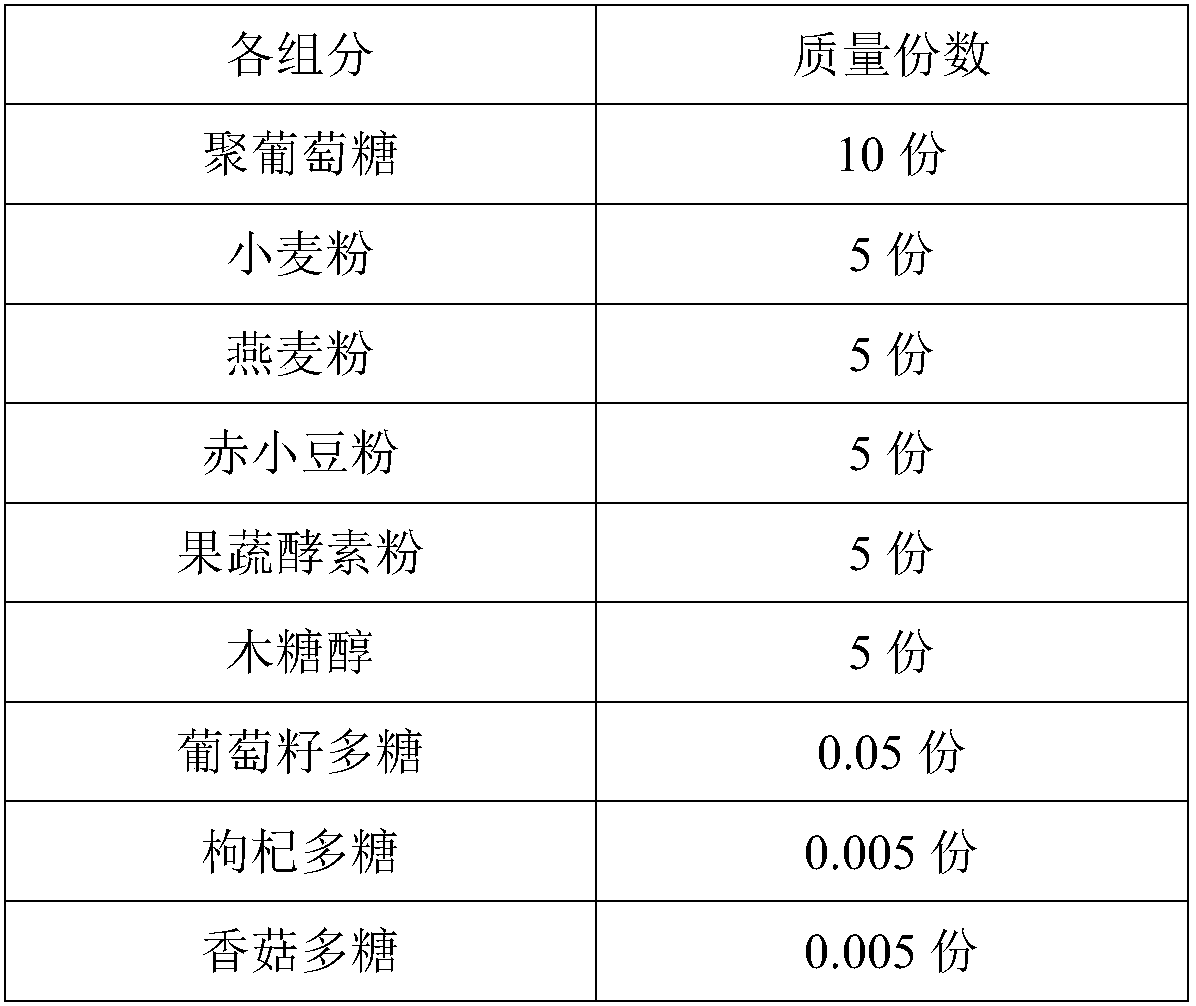

[0031] The raw materials of the probiotic solid beverage in this example were mixed according to the parts by mass in Table 1.

[0032] Table 1

[0033]

[0034]

[0035] Wherein, the raw material of fruit and vegetable enzyme powder is mixed by each component of the mass fraction in table 2.

[0036] Table 2

[0037] cranberry

1 copy

sweet orange fruit

1 copy

mango

1 copy

mulberries

3 copies

[0038] After crushing and mixing the raw materials in Table 2, add brown sugar and lactic acid bacteria with a weight of 80% of the total mass of fruit and vegetable enzyme powder raw materials to the mixture, ferment for 20 days at 25°C, and obtain a primary fermented fruit and vegetable enzyme stock solution through infiltration, sedimentation, and filtration Continue to ferment the primary fermented fruit and vegetable enzyme stock solution at 25°C for 6 months, then concentrate at low temperature and freeze-dry to obtain the...

Embodiment 2

[0041] The raw materials of the probiotic solid beverage in this embodiment were mixed according to the parts by mass in Table 3.

[0042] table 3

[0043] Each component

parts by mass

resistant dextrin

30 copies

oat flour

4 parts

peanut powder

3 copies

mung bean powder

3 copies

Fruit and Vegetable Enzyme Powder

1 copy

10 copies

0.05 parts

Lycium barbarum polysaccharide

0.005 copies

0.005 copies

Dendrobium officinale

0.005 copies

[0044] Wherein, the raw material of fruit and vegetable enzyme powder is mixed by each component of the mass fraction in table 4.

[0045] Table 4

[0046] blueberry

2 copies

cherry

2 copies

banana

2 copies

pumpkin

2 copies

[0047] After crushing and mixing the raw materials in Table 4, add brown sugar and lactic acid bacteria w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com