Processing method and product of customized antibacterial and antiviral photocatalyst filter element

A processing method and photocatalyst technology, applied in separation methods, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of weak catalytic activity and effect, and achieve the effects of avoiding secondary pollution, avoiding poisoning failure, and ensuring contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, a processing method of a custom-made antibacterial and antiviral photocatalyst filter element, based on the composite manufacturing process of glass long fiber mat and photocatalyst, including the preparation of photocatalyst suspension and the composite positioning of nano-scale crystal grains on the glass long fiber, Specifically include the following process steps:

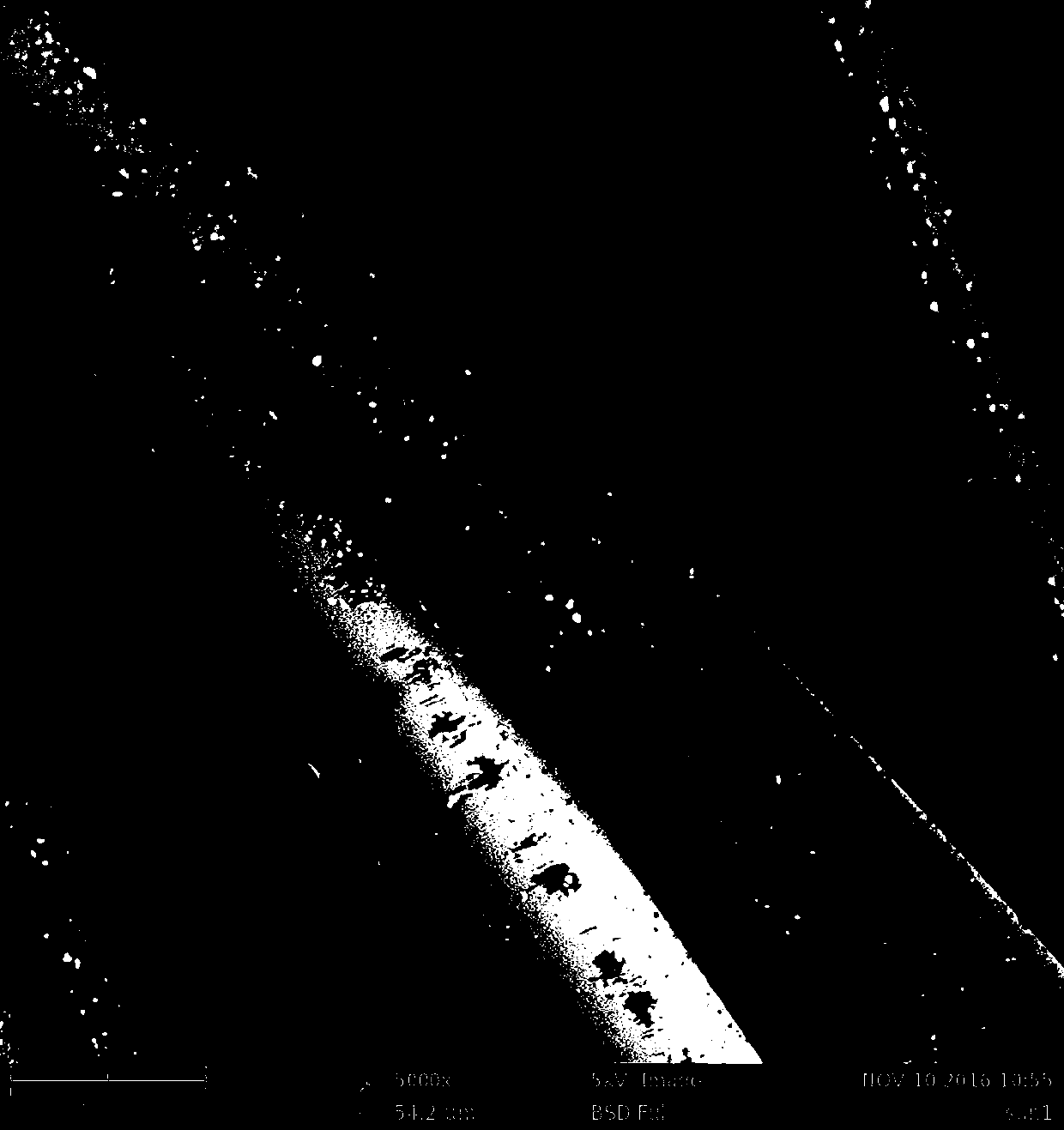

[0040] . Material preparation: select the glass fiber mat made of continuous raw silk, wash and dry it for later use; prepare supporting photocatalyst dispersion mother liquor: mix 1000g of titanium oxysulfate with an average particle size of 25nm in 50000ml of water, add 11000ml of 2.5% Ammonia water, settling for 30min, remove the supernatant, centrifuge at 8000r / min, mix the centrifuged solid matter with 9000ml of water, ultrasonic, and stir evenly; then add 1000ml of acrylate, ultrasonically disperse for 30min.

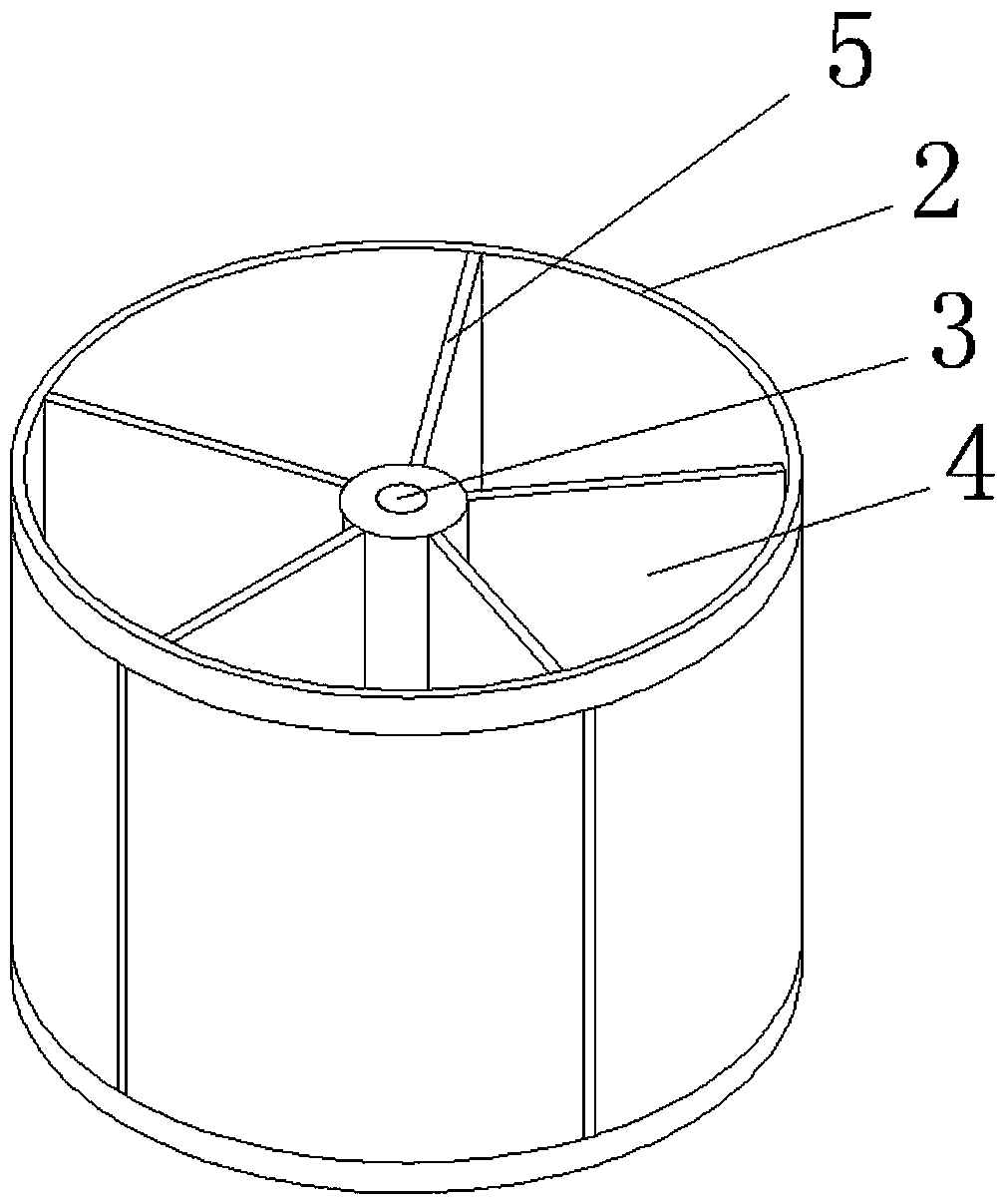

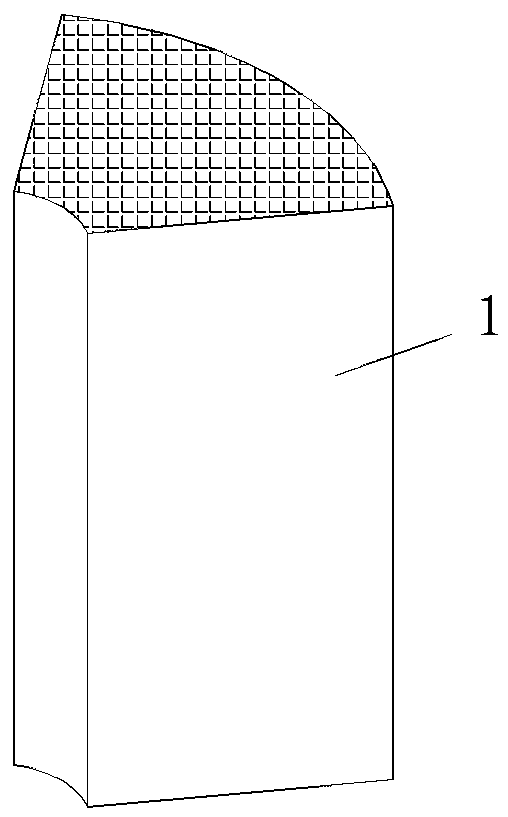

[0041] . Forming and support of the basic filter unit: process and p...

Embodiment 2

[0046] Embodiment 2, the processing method of the photocatalyst filter element is basically the same as Embodiment 1, the difference is that the cylindrical frame 2 in the communication positioning mechanism is thinner and longer than Embodiment 1, and the upper and lower cover structures are changed to form parallel filtering channels. In this embodiment, the upper cover 6 includes an air outlet 6-1 arranged in the center and an upper sealing pressure plate 6-2 and an upper sealing pressure plate 6-2 which are arranged in the lower part and match the air outlet ports of the filter unit housing 1. Attach the elastic gasket. The lower cover 7 includes an air inlet 7-1 with a ring-shaped cross-section arranged in the center and a lower sealing plate that is arranged on the upper part of the lower cover 7 and matches each air intake port of the filter unit housing 1. The lower sealing plate is attached The lower elastic gasket is evenly distributed between the air inlet 7-1 and t...

Embodiment 3

[0047] Embodiment 3, an antibacterial and anti-virus filter device, the filter element of which is manufactured by the process of Embodiment 1. Blower 12 is installed in the bottom of lower cover 7 ', and base 8 and loam cake 9 with ventilation structure are installed at both ends again, and gac coarse filter screen 10 and HEPA filter screen 11 are installed in base 8. Loam cake 9 and loam cake 6 ' integral installation. The filter device has a good effect of killing and degrading bacteria and viruses, and the sterilization rate of one pass can reach more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com