Preparation and application of solid phosphorescent probe material based on Mn-doped ZnS quantum dot

A quantum dot and phosphorescence technology, which is applied in the preparation and application of solid phosphorescence probe materials based on Mn-doped ZnS quantum dots, can solve the problems of high cost, poor selectivity, complicated operation, etc., and achieves stable properties, excellent performance, Simple steps to prepare the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

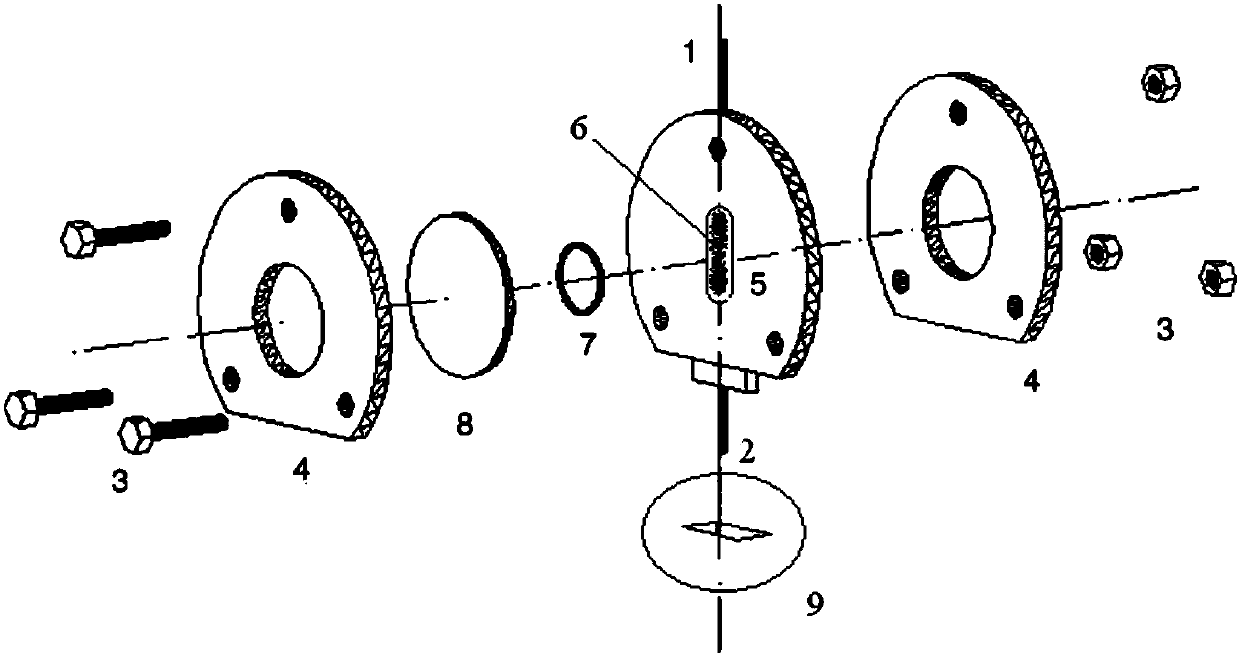

[0032] A method for preparing a solid phosphorescent probe material of Mn-doped ZnS quantum dots in this embodiment, comprising the following steps:

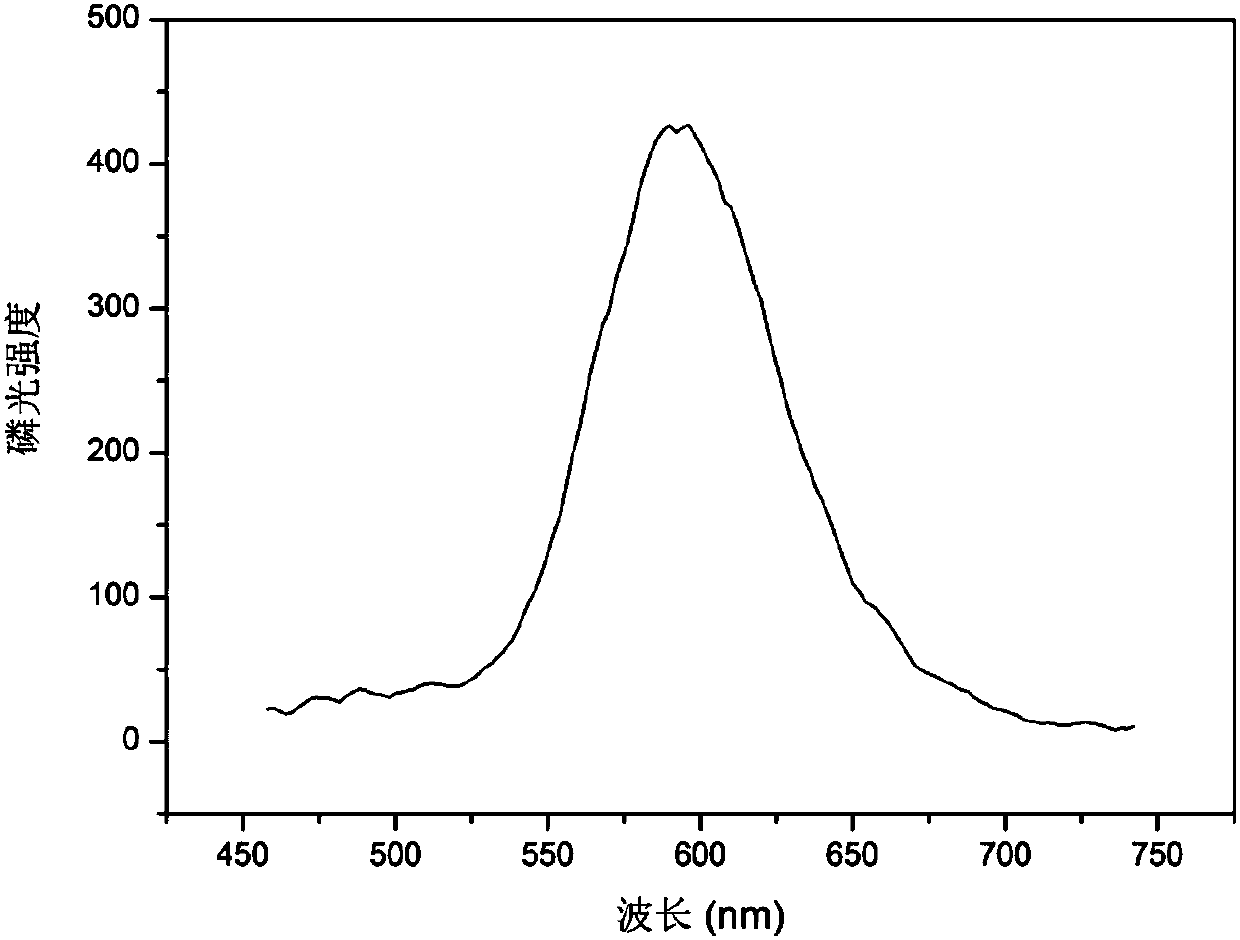

[0033] (1) Preparation of Mn-doped ZnS quantum dots: N-acetyl-L-cysteine, Zn(Ac) 2 and Mn(Ac) 2 Mix according to the molar ratio of 3:1:0.04, adjust the pH value of the mixed solution to 11 with NaOH, and stir for 30 minutes at room temperature under the protection of nitrogen; under continuous stirring, add Zn(Ac) 2 Equimolar amount of Na 2 S aqueous solution, continue to react for 30min; then the reaction solution is heated to 50 ° C, aged in the air for 2h to obtain the crude product of Mn-doped ZnS quantum dots, and then purified and vacuum-dried to obtain Mn-doped ZnS quantum dot solid powder; The morphology, particle size and dispersion of the prepared N-acetyl-L-cysteine-modified Mn-doped ZnS quantum dots were observed and analyzed by transmission electron microscopy, as shown in figure 2 As shown, the quantum dots ar...

Embodiment 2

[0043] A method for preparing a solid phosphorescent probe material of Mn-doped ZnS quantum dots in this embodiment comprises the following steps:

[0044] (1) Preparation of Mn-doped ZnS quantum dots: L-cysteine, Zn(Ac) 2 and Mn(Ac) 2 Mix according to the molar ratio of 3:1:0.04, adjust the pH value of the mixed solution to 11 with NaOH, and stir for 20 minutes at room temperature under the protection of nitrogen; under continuous stirring, add Zn(Ac) 2 Equimolar amount of Na 2 S aqueous solution, continue to react for 20min; then heat the reaction solution to 50°C, and age in air for 2.5h to obtain the crude product of Mn-doped ZnS quantum dots, and then obtain Mn-doped ZnS quantum dot solids by purification and vacuum drying powder;

[0045] (2) Activate the surface of fumed silica: add 1 g of fumed silica and 20 ml of activating reagent to the flask, the activating reagent is prepared by 3-aminopropyltriethoxysilane and methanol at a volume ratio of 1:15 The mixed solu...

Embodiment 3

[0054] A method for preparing a solid phosphorescent probe material of Mn-doped ZnS quantum dots in this embodiment, comprising the following steps:

[0055] (1) Preparation of Mn-doped ZnS quantum dots: mercaptoacetic acid, Zn(Ac) 2 and Mn(Ac) 2 Mix according to the molar ratio of 3:1:0.04, adjust the pH value of the mixed solution to 11 with NaOH, and stir for 40 minutes at room temperature under the protection of nitrogen; under continuous stirring, add Zn(Ac) 2 Equimolar amount of Na 2 S aqueous solution, continue to react for 40min; then heat the reaction solution to 50°C, and age in air for 3h to obtain the crude product of Mn-doped ZnS quantum dots, and then obtain Mn-doped ZnS quantum dot solid powder by purification and vacuum drying ;

[0056] (2) Activate the surface of fumed silica: add 1 g of fumed silica and 20 ml of activating reagent to the flask, the activating reagent is prepared by 3-aminopropyltriethoxysilane and methanol at a volume ratio of 1:25 The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com