Same-temperature-field multichannel honeycomb array crucible

A same-temperature, multi-channel technology is applied in the field of microwave-based high-throughput micro-manufacturing devices and multi-channel honeycomb array crucibles in the same temperature field, which can solve the problems of long heating time, low heating efficiency, and high cost, and improve heating efficiency. , high heating efficiency and small monomer size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] This embodiment is a one-time high-throughput preparation of multiple small-sized alloy samples with composition gradient distribution under the same temperature field.

[0058] 1) Weigh 11 parts of 100g of H13 alloy powder (without cobalt) as the parent material, then weigh 10 parts of pure cobalt metal powder whose mass varies according to a certain gradient, and mix them with 10 parts of H13 alloy powder to obtain cobalt 9 series of 11 mixed powder materials whose content varies from 0-10%;

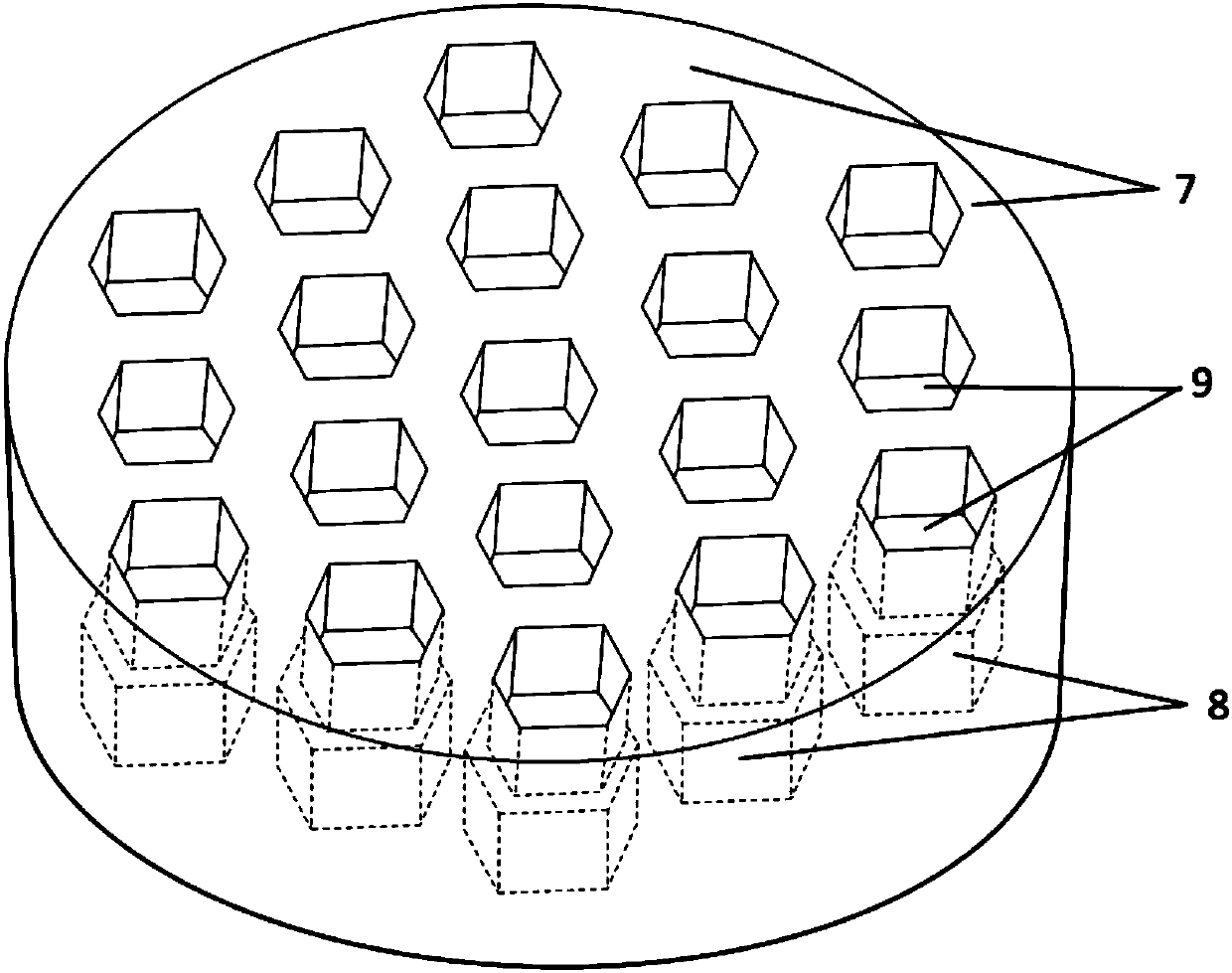

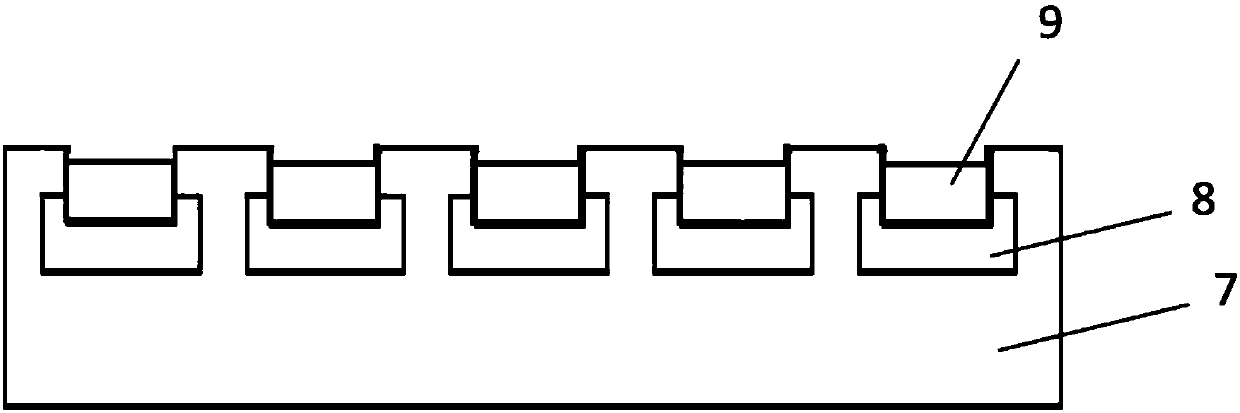

[0059] 2) Fill 11 parts of the mixed powder material 9 into the honeycomb array crucible 3 with the same temperature field. The individual honeycomb crucibles 8 in the multi-channel honeycomb array crucible 3 with the same temperature field are made of materials with the same microwave energy absorption.

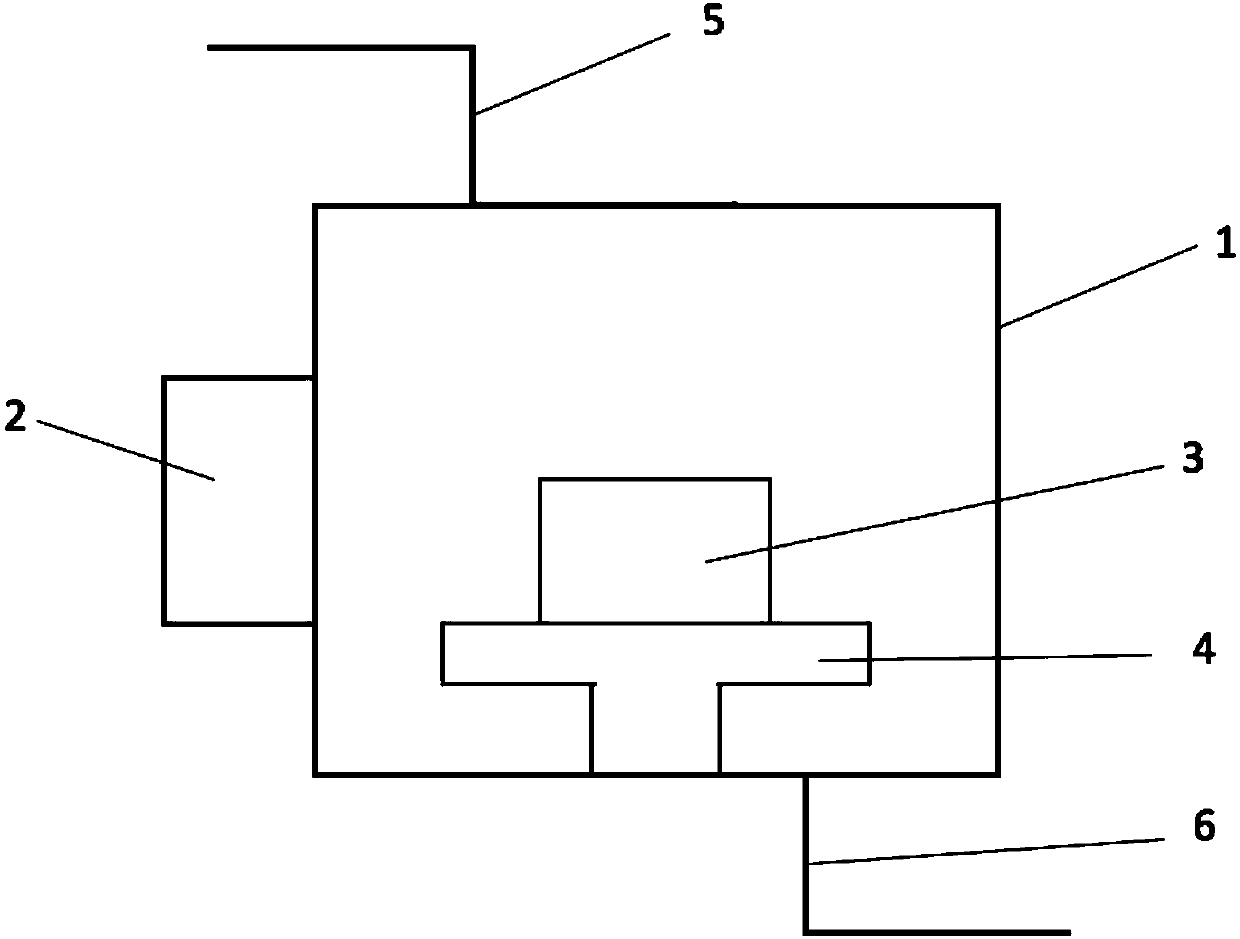

[0060] 3) Place the multi-channel honeycomb array crucible 3 with the same temperature field on the loading platform 4 in the microwave cavity 1, and seal the microwave cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com