Application of waste lee extract in sewage treatment

A technology of sewage treatment and extract, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems that the precise application needs to be developed, and achieve the effect of improving social and economic benefits, expanding application ideas, and promoting rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

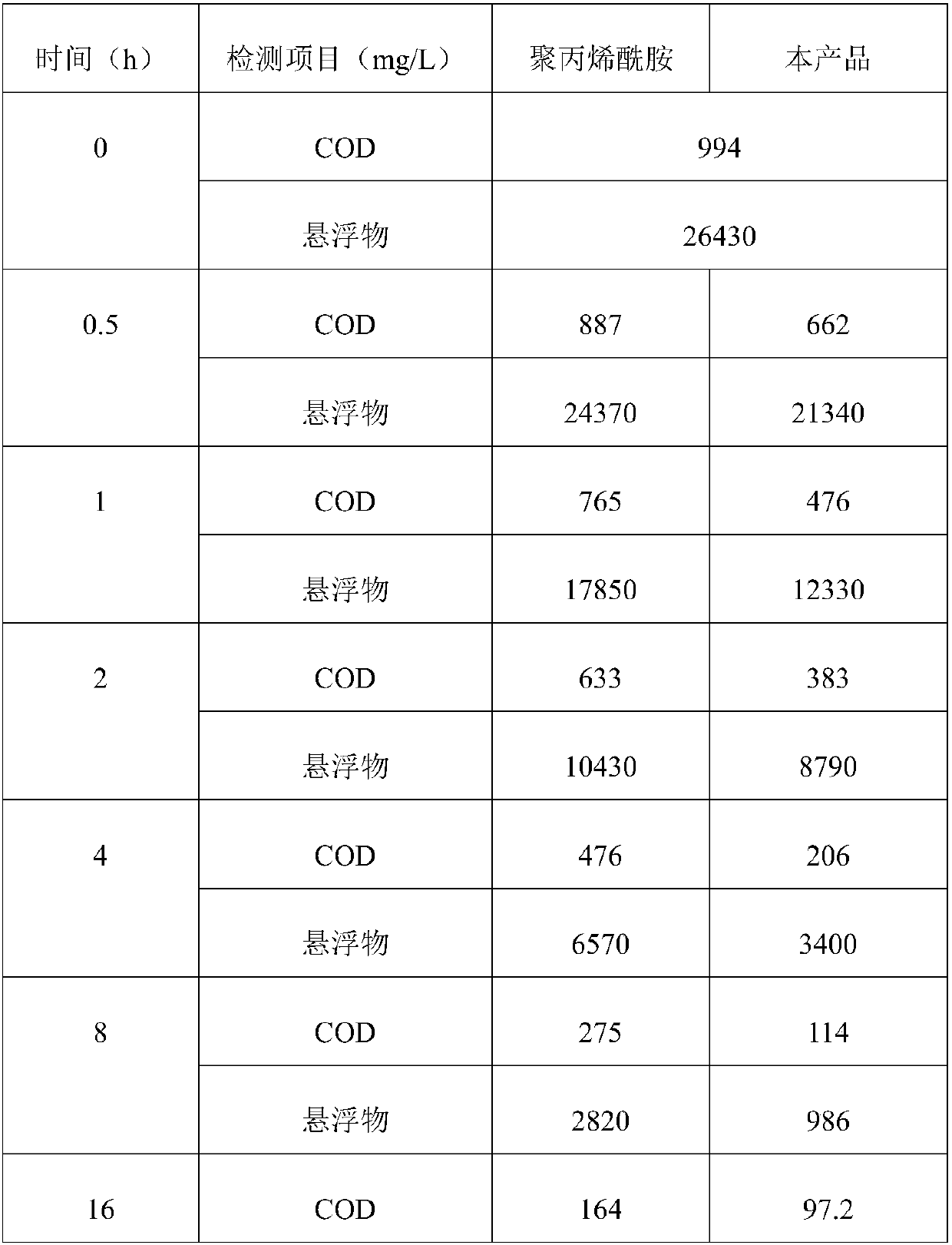

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for preparing the waste residue extract. The waste residue extraction obtained according to the method mainly contains amylopectin, and the amylopectin can be used in the sewage treatment process. The method comprises the steps of:

[0038] Step 1: Take the freshly steamed dregs and grind it into a paste with a rolling juicer while it is still wet. It is advisable to disperse the pasty grains in clear water to form a suspension that is easy to stir, then add sodium carbonate to adjust the pH of the suspension to 9, and soak for 2 hours at a speed of 300r / min to obtain an alkali foam.

[0039] Step 2: Filter the alkali bubble solution with gauze to obtain the first filter residue and the first filtrate. Put the first filter residue back into clean water to form a suspension, soak it for 4 hours under the condition of 150r / min to obtain a blister solution, and filter the blister solution with gauze to obtain a second filtrate and a secon...

Embodiment 2

[0043] This embodiment provides a method for preparing the waste residue extract. The waste residue extraction obtained according to the method mainly contains amylopectin, and the amylopectin can be used in the sewage treatment process. The method comprises the steps of:

[0044] Step 1: Take the freshly steamed dregs and grind it into a paste with a rolling juicer while it is still wet. It is advisable to disperse the pasty discarded grains in clear water to form a suspension that is easy to stir, then add sodium carbonate to adjust the pH of the suspension to 10, and soak for 5 hours at a speed of 250r / min to obtain an alkali foam.

[0045] Step 2: Filter the alkali bubble solution with gauze to obtain the first filter residue and the first filtrate. Put the first filter residue back into clean water to form a suspension, soak it for 3 hours under the condition of 160r / min to obtain a blister solution, and filter the blister solution with gauze to obtain a second filtrate ...

Embodiment 3

[0049] This embodiment provides a method for preparing the waste residue extract. The waste residue extraction obtained according to the method mainly contains amylopectin, and the amylopectin can be used in the sewage treatment process. The method comprises the steps of:

[0050] Step 1: Take the freshly steamed dregs and grind it into a paste with a rolling juicer while it is still wet. It is advisable to disperse the pasty grains in clear water to form a suspension that is easy to stir, then add sodium carbonate to adjust the pH of the suspension to 12, and soak for 8 hours at a speed of 200r / min to obtain an alkali foam.

[0051] Step 2: Filter the alkali bubble solution with gauze to obtain the first filter residue and the first filtrate. Put the first filter residue back into clean water to form a suspension, soak it for 2 hours under the condition of 180r / min to obtain a blister liquid, and filter the blister liquid with gauze to obtain a second filtrate and a second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com