Spontaneous-heating dehumidification material and preparation method thereof

A self-heating, calcite technology, applied in the field of road materials, can solve problems such as water damage on asphalt pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

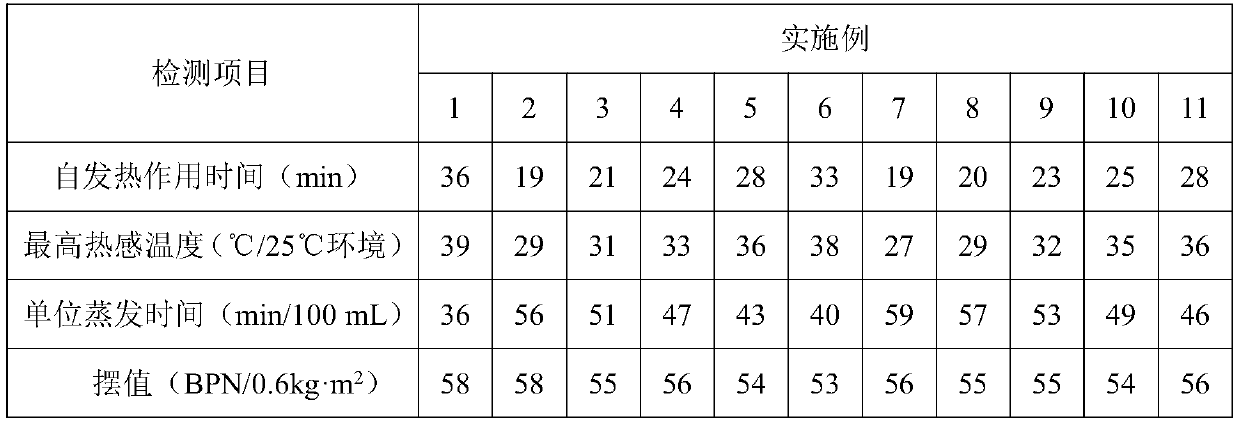

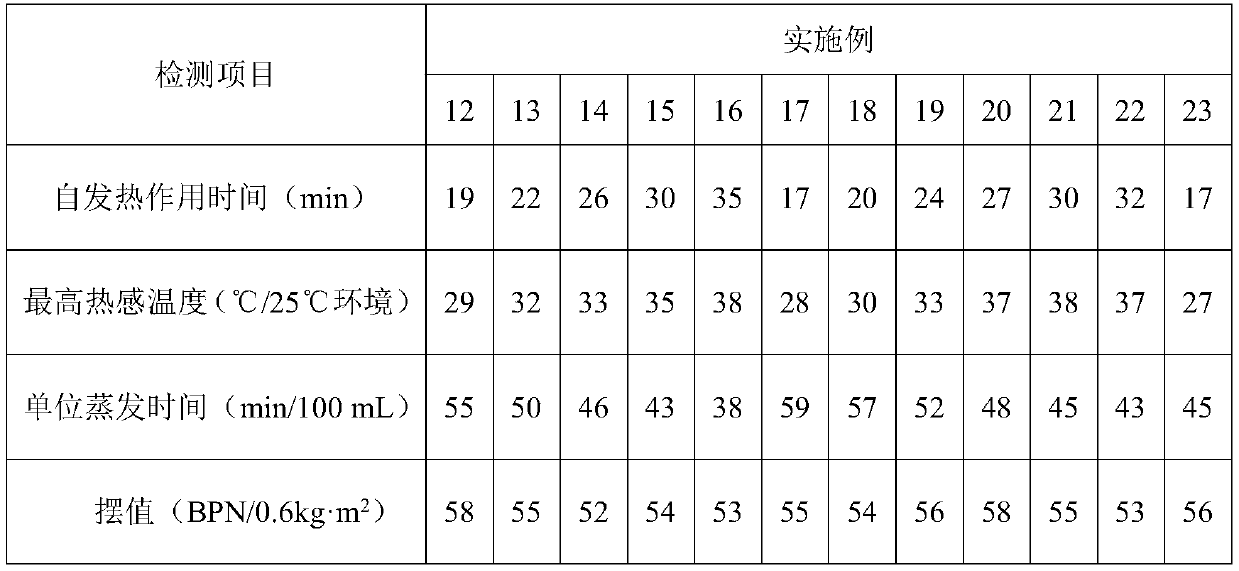

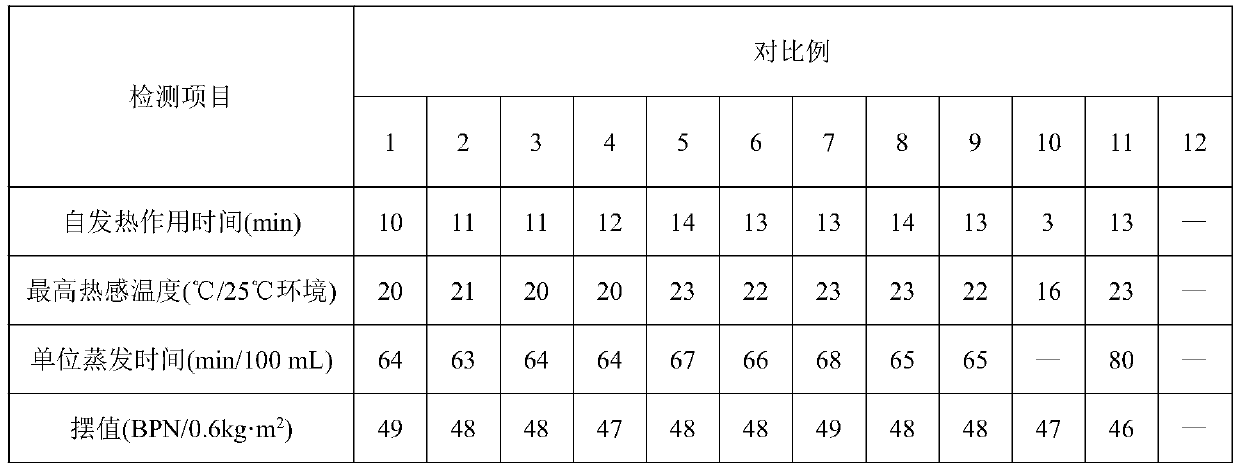

Examples

Embodiment 1

[0149] Example 1 Self-heating dehumidification material

[0150] A self-heating dehumidifying material, calculated in parts by weight, comprising the following components: 100 parts of polyurethane resin, 21 parts of polyetheramine, 6 parts of ZX-687 seaweed powder, 13 parts of nonionic surfactant activated calcite, carbonic acid Potassium powder 0.9 parts, electric furnace nickel iron powder 5 parts, W-5 type tungsten powder 4 parts, zeolite powder 8 parts, metallic carbon nanotube 2.2 parts, GH-1A type white carbon black 10 parts, rubber accelerator M 2 parts , 2.6 parts of didodecanol ester antioxidant, 7 parts of active calcium powder, 9 parts of propylene glycidyl ether.

[0151] The technical indicators of each component in this embodiment are as follows: The amine value of polyetheramine is 400mg·KOH·g -1 , The fineness of ZX-687 seaweed powder is 180 mesh, the PH value is 7, the fineness of calcite activated by non-ionic surfactant is 450 mesh, and the water-insoluble conte...

Embodiment 2

[0158] Example 2 Self-heating dehumidification material

[0159] The components of the self-heating dehumidification material formula and the weight parts of each component of this embodiment are different from those of Embodiment 1. specifically:

[0160] A self-heating dehumidification material, in parts by weight, comprising the following components: 100 parts of phenolic resin, 15 parts of isophorone diamine, 4 parts of ZX-687 seaweed powder, and calcite 8 activated by non-ionic surfactant Parts, 0.4 parts of potassium carbonate powder, 3 parts of electric furnace nickel iron powder, 2 parts of W-2 type tungsten powder, 5 parts of zeolite powder, 1 part of metallic carbon nanotubes, 6 parts of GH-1A white carbon black, rubber accelerator 1 part of M, 1 part of phosphite antioxidant, 5 parts of light calcium powder, 6 parts of styrene.

[0161] The technical indicators of each component in this embodiment are as follows: The amine value of isophorone diamine is 310 mg·KOH·g -1 ,...

Embodiment 3

[0168] Example 3 Self-heating dehumidifying material

[0169] The components of the self-heating dehumidification material formula and the weight parts of each component of this embodiment are different from those of Embodiment 1. specifically:

[0170] A self-heating dehumidifying material, in parts by weight, comprising the following components: 100 parts of phenolic resin, 18 parts of isophorone diamine, 5 parts of ZX-687 seaweed powder, and 12 parts of calcite activated by non-ionic surfactant Parts, 0.8 parts of potassium carbonate powder, 4 parts of electric furnace nickel iron powder, 3 parts of W-2 type tungsten powder, 7 parts of zeolite powder, 1.8 parts of metallic carbon nanotubes, 9 parts of GH-1A white carbon black, rubber accelerator 1.6 parts of M, 2 parts of phosphite antioxidant, 6 parts of light calcium powder, 8 parts of styrene.

[0171] The technical indicators of each component in this embodiment are as follows: The amine value of isophorone diamine is 400 mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com