Method for hydrating cyclohexene to prepare cyclohexanol

A cyclohexene hydration and cyclohexanol technology, which is applied in the preparation of hydroxyl compounds, organic compounds, and hydroxyl addition preparations, can solve the problems of chemical balance limitations, high energy consumption, and poor solvent and solubilization effects. Achieve the effects of simple process flow, low energy consumption and safe reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 cyclohexene hydration prepares cyclohexanol

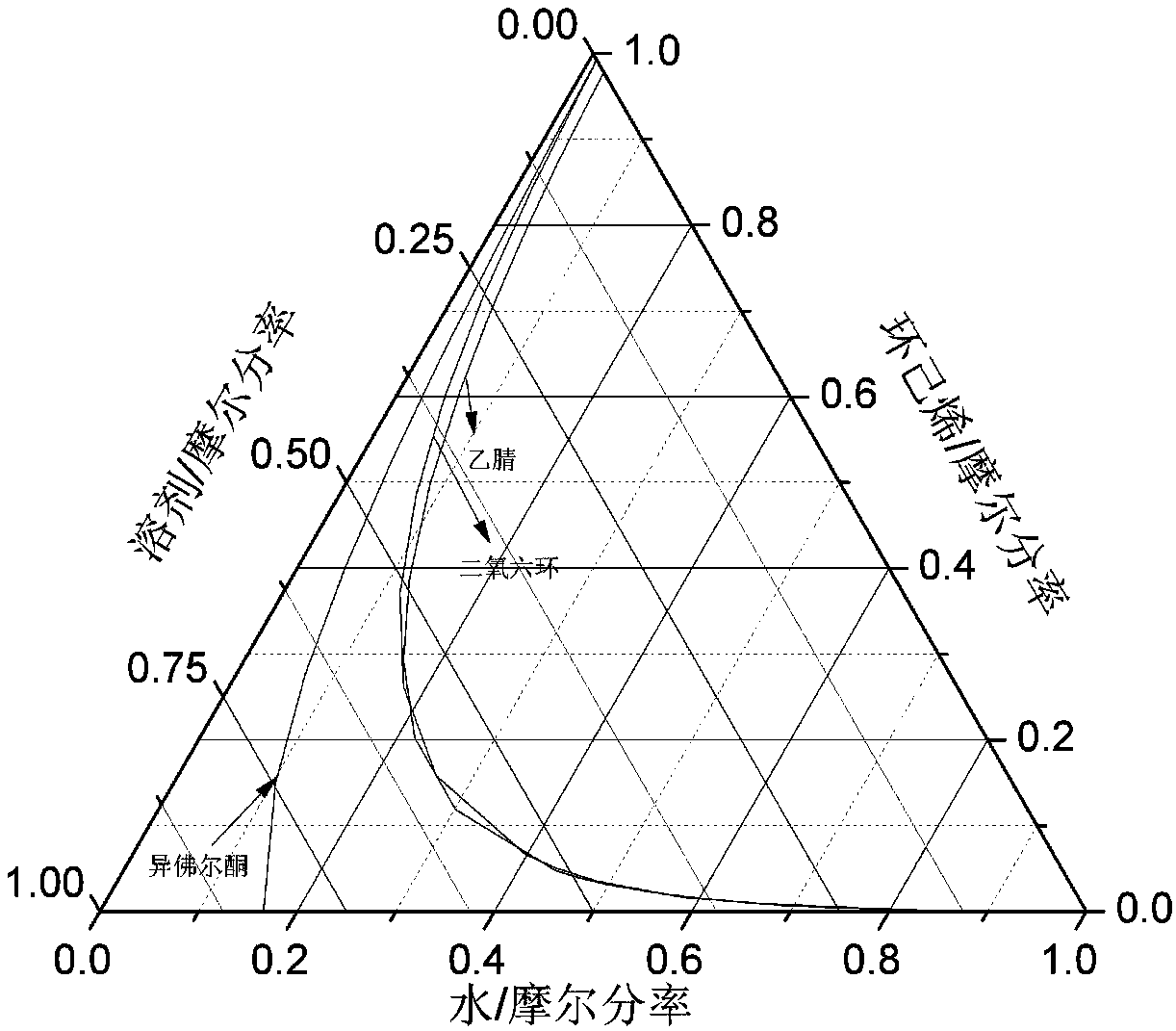

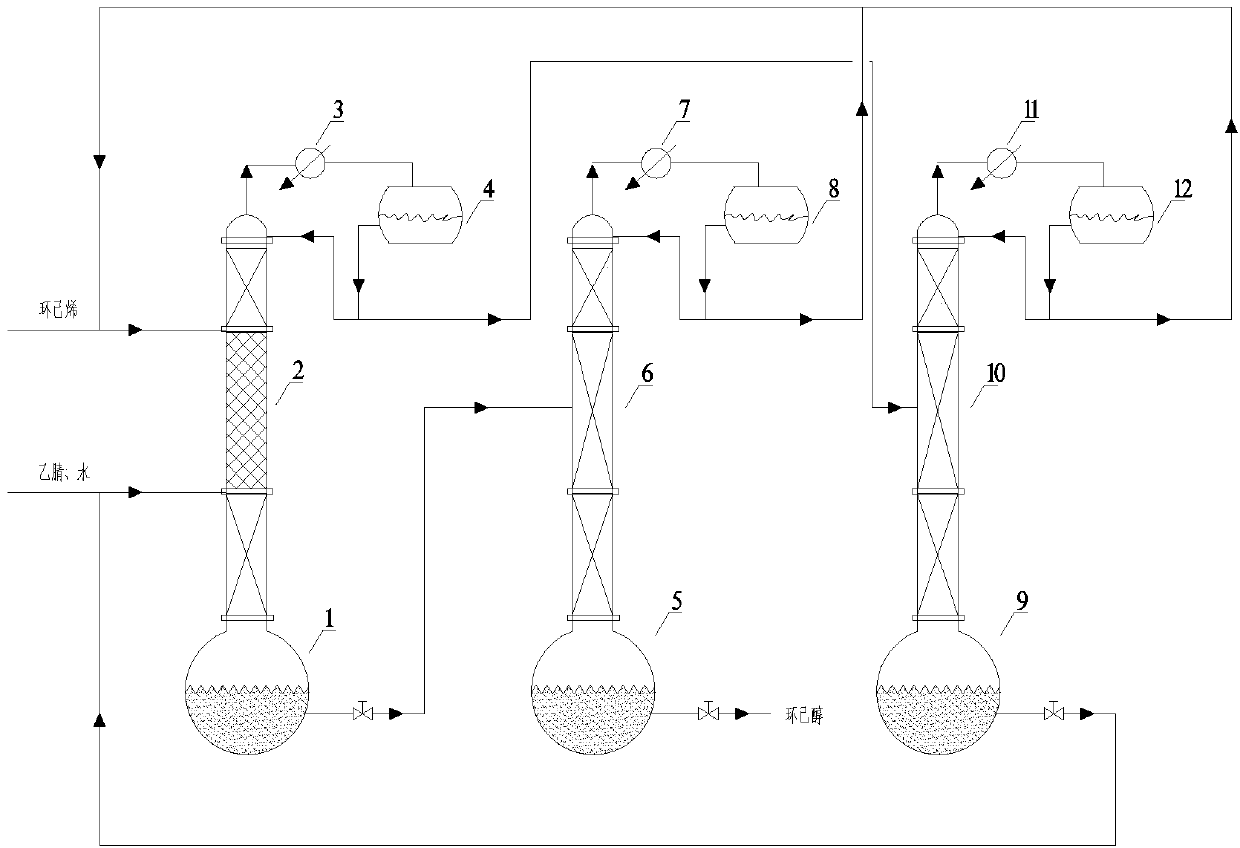

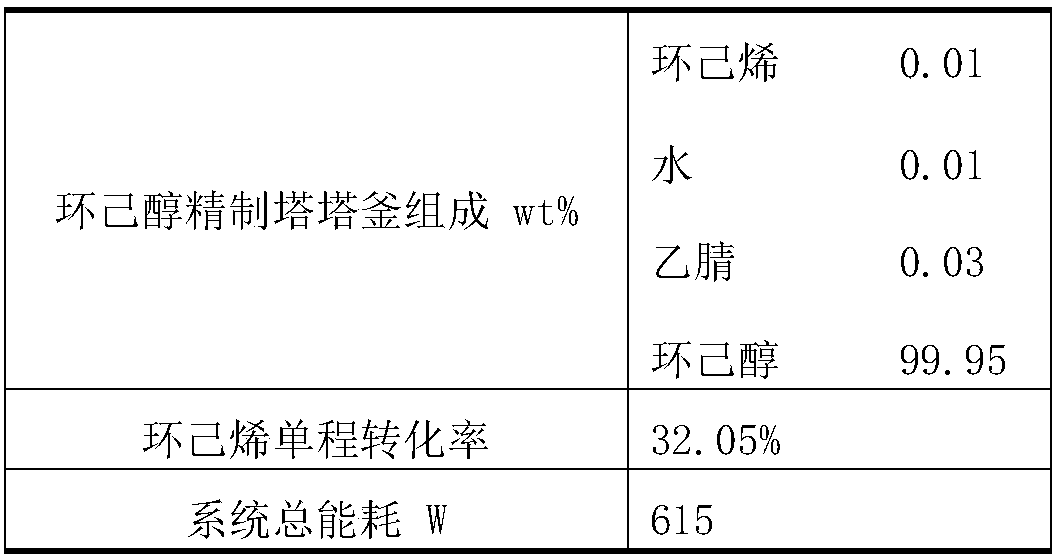

[0024] Add 50% cyclohexanol, 25% water, and 25% acetonitrile solution to the reactor of the reactive distillation column, and reach 80% of the liquid level in the reactor of the reactive distillation column, add a certain amount of zeolite to prevent bumping, and heat the reactor , control the heating power of the catalytic distillation tower to 410w, and turn on the tower insulation switch to control the pressure inside the tower. When the temperature of the tower reaches 170°C, start feeding, and the feed molar ratio of water and cyclohexene is controlled at 3.0:1.0, the mol ratio of acetonitrile and cyclohexene is controlled at 9.0:1.0, the cyclohexene feed is 3mol / h, the feed temperature is room temperature, the water feed is 6mol / h, and the acetonitrile feed is 15mol / h h, the feed temperature of acetonitrile and water mixture is 80°C, until the reactive distillation column starts to reflux, stop feeding, th...

Embodiment 2

[0027] Embodiment 2 cyclohexene hydration prepares cyclohexanol

[0028]Add 50% cyclohexanol, 25% water, and 25% acetonitrile solution to the reactor of the reactive distillation tower, and reach 80% of the liquid level of the tower reactor, add a certain amount of zeolite to prevent bumping, heat the tower reactor, and control the catalytic concentration. The heating power of the distillation tower is 400w, and the insulation switch of the tower is turned on to control the pressure inside the tower. When the temperature of the tower reaches 170°C, the feed is started. The feed molar ratio of water and cyclohexene is controlled at 1.5:1.0. The mol ratio of acetonitrile and cyclohexene is controlled at 3.0:1.0, and cyclohexene feed is 3mol / h, and feed temperature is room temperature, and water feed rate is 4.5mol / h, and acetonitrile feed rate is 12mol / h, mixing Liquid feed temperature is 80 ℃, until the reactive distillation column starts to reflux, stop feeding, total reflux f...

Embodiment 3

[0031] Embodiment 3 cyclohexene hydration prepares cyclohexanol

[0032] Add 50% cyclohexanol, 25% water, and 25% acetonitrile solution to the reactor of the reactive distillation tower, and reach 80% of the liquid level of the tower reactor, add a certain amount of zeolite to prevent bumping, heat the tower reactor, and control the catalytic concentration. The heating power of the distillation tower is 430w, and the insulation switch of the tower is turned on to control the pressure inside the tower. When the temperature of the tower reaches 170°C, the feed is started, and the feed molar ratio of water to cyclohexene is controlled at 5.0:1.0. The mol ratio of acetonitrile and cyclohexene is controlled at 15.0:1.0, and cyclohexene feed is 3mol / h, and feed temperature is room temperature, and water feed rate is 9mol / h, and acetonitrile feed rate is 21mol / h, mixed liquid The feed temperature is 80°C, until the reactive distillation tower starts to reflux, stop feeding, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com