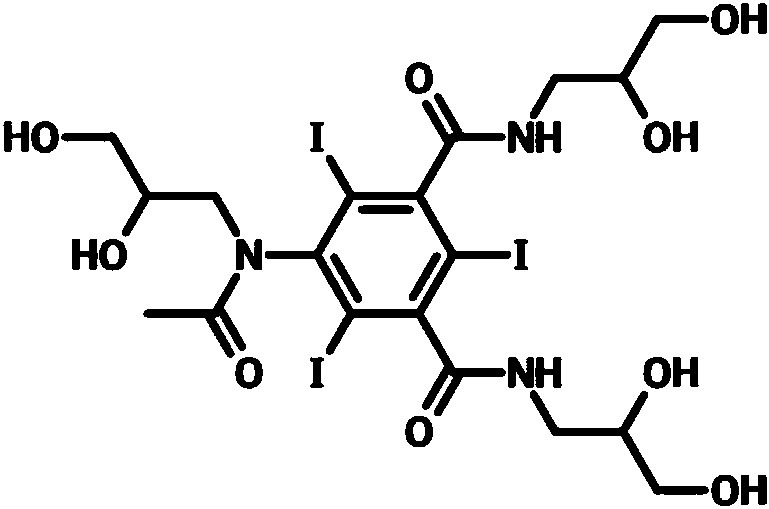

Fine purification method for iohexol

A technology of iohexol and purification, applied in the field of drug purification, can solve problems such as adverse reactions, achieve pollution-free costs, reduce environmental pressure and costs, and achieve high yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 4.4 g of crude iohexol (98.68% purity) was dissolved in 10 ml of deionized water, stirred to dissolve, filtered through a filter membrane with a pore size of 0.45 μm, and the filtrate was collected for later use. A chromatographic column of 15 × 310mm was used, and UniBPC60 polymer microspheres (produced by Suzhou Nawei Technology Co., Ltd.) were used as the packing material of the chromatographic column, and the packing volume was 55m1. The column was equilibrated with deionized water before loading the sample, and then eluted with deionized water. The solution of the target peak was collected in sections, and the component solutions meeting the requirements were summarized. After high-performance liquid chromatography analysis, the purity of iohexol in the eluent was above 99.5%, and the yield was 93%. The sum of the peak areas of each impurity in iohexol is less than 0.6% of the total peak area, the peak area of other individual impurities except O-alkyl compound i...

Embodiment 2

[0036] Take 42g of crude iohexol (98.68% purity) and dissolve it in 130ml of deionized water, stir to dissolve, filter with a filter membrane with a pore size of 0.45 μm, and collect the filtrate for later use. A DAC50 chromatographic column with a column height of 20 cm was used, and UniBPC60 polymer microspheres (produced by Suzhou Nanwei Technology Co., Ltd.) were used as the chromatography column filler, and the column volume was 392 ml. The column was equilibrated with deionized water before loading the sample, and then eluted with deionized water. The solution of the target peak was collected in sections, and the component solutions meeting the requirements were summarized. After high-performance liquid chromatography analysis, the purity of iohexol in the eluent was above 99.7%, and the yield was 90%. The sum of the peak areas of each impurity in iohexol is less than 0.6% of the total peak area, the peak area of other individual impurities except O-alkyl compound impu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com