Method for using normal propyl alcohol-seignette salt double-aqueous-phase system to extract, separate and purify phlorizin

A technology of potassium sodium tartrate and two-phase system, which is applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., to achieve the effects of easy integration technology, easy amplification, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

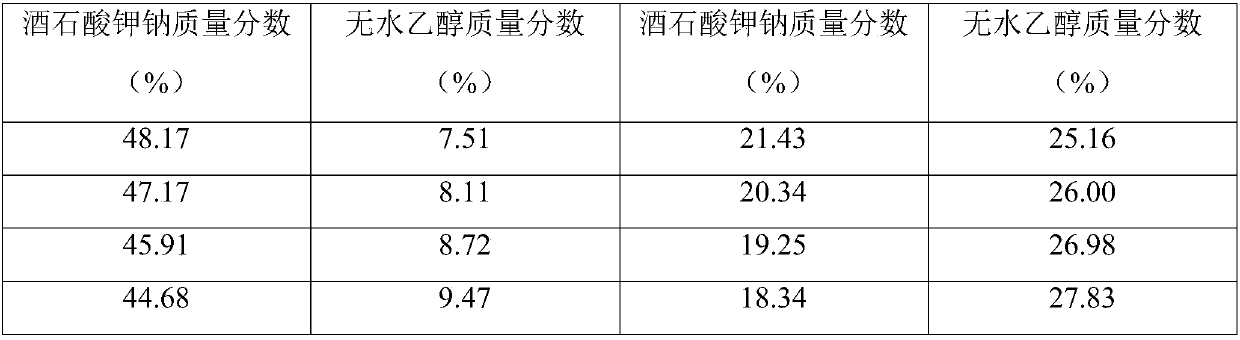

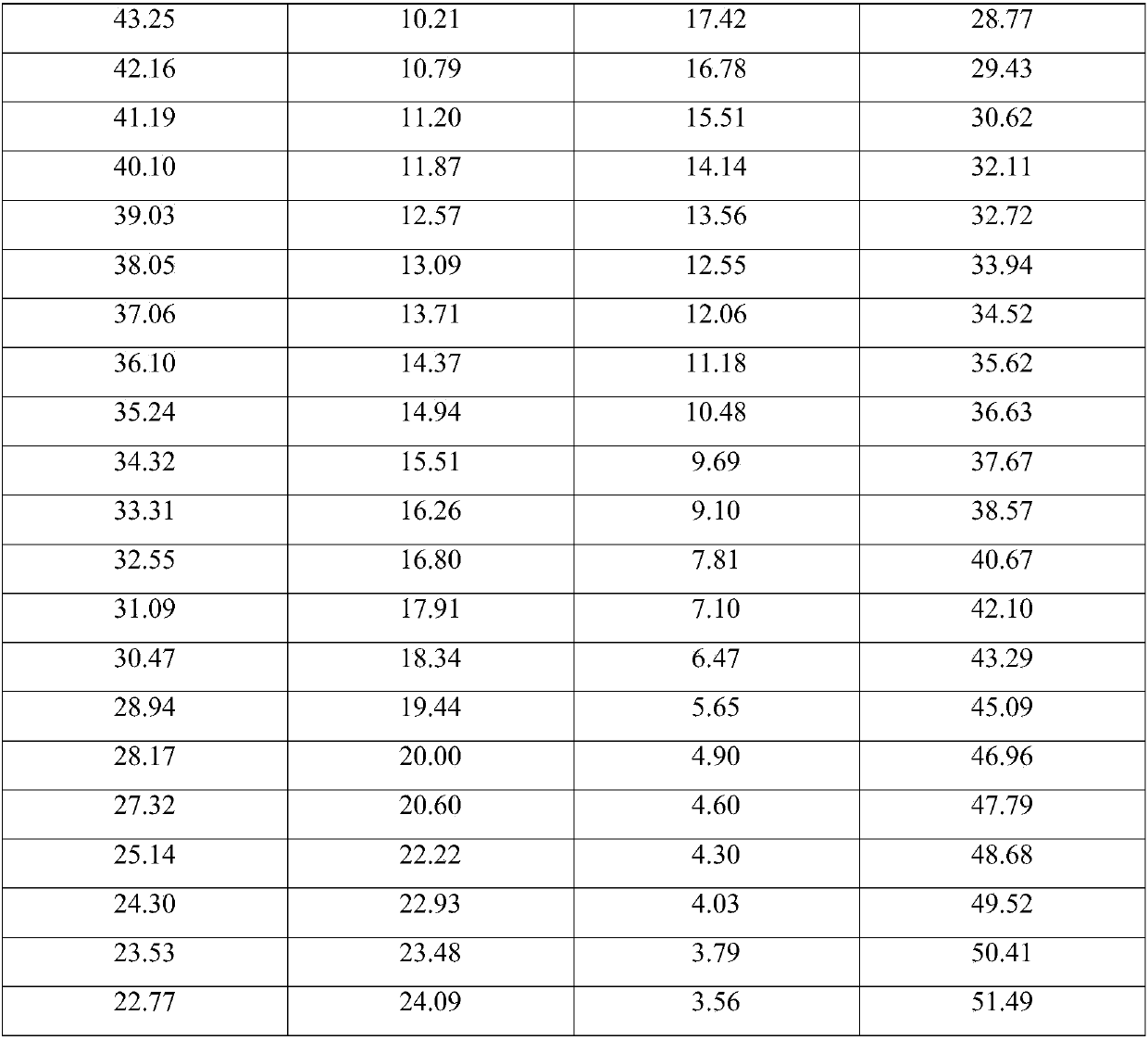

Method used

Image

Examples

Embodiment 1

[0049] Get 1000g of Coryne fruticosa leaves (5.62% phlorizin content), pulverize through a 50 mesh sieve, add 10Kg of the two-phase system extraction solvent composed of n-propanol-potassium sodium tartrate-water, and add n-propanol in the two-phase system extraction solvent. The mass fraction of alcohol is 25.75%, the mass fraction of potassium sodium tartrate is 11.00%, the mass fraction of water is 63.25%, microwave-assisted extraction is 30 minutes, extraction temperature is 80 ℃, microwave power is 400W, static phase separation, phase separation The temperature is 30°C, the phase separation time is 4 hours, separate the upper phase, add n-propanol of equal weight, let it stand at 4°C for 48 hours, filter, concentrate the filtrate under reduced pressure, dry the crude phlorizin, and use a recrystallization solvent For recrystallization, the recrystallization solvent was 65% by volume of isopropanol and 35% by volume of water to obtain 44.45 g of phlorizin crystals (transfer...

Embodiment 2

[0061] Get 1000g of Coryne fruticosa leaves (5.62% phlorizin content), pulverize through a 50 mesh sieve, add 10Kg of the two-phase system extraction solvent composed of n-propanol-potassium sodium tartrate-water, and add n-propanol in the two-phase system extraction solvent. The mass fraction of alcohol is 35.26%, the mass fraction of potassium sodium tartrate is 7.97%, the mass fraction of water is 56.77%, microwave-assisted extraction is 30 minutes, extraction temperature is 80 ℃, microwave power is 600W, static phase separation, phase separation The temperature is 30°C, the phase separation time is 2 hours, separate the upper phase, add n-propanol of equal weight, stand at 4°C for 48 hours, filter, concentrate the filtrate under reduced pressure, dry the crude phlorizin, and use a recrystallization solvent Recrystallization, the recrystallization solvent is 65% volume of isopropanol and 35% volume of water, to obtain 46.31 g of phlorizin crystals (82.4% transfer rate).

[...

Embodiment 3

[0065] Get 1000g of Coryne fruticosa leaves (5.62% phlorizin content), pulverize through a 50 mesh sieve, add 10Kg of the two-phase system extraction solvent composed of n-propanol-potassium sodium tartrate-water, and add n-propanol in the two-phase system extraction solvent. The mass fraction of alcohol is 44.88%, the mass fraction of potassium sodium tartrate is 4.88%, the mass fraction of water is 50.24%, microwave-assisted extraction is 30 minutes, extraction temperature is 80 ℃, microwave power is 800W, static phase separation, phase separation The temperature is 30°C, the phase separation time is 4 hours, separate the upper phase, add n-propanol of equal weight, let it stand at 4°C for 48 hours, filter, concentrate the filtrate under reduced pressure, dry the crude phlorizin, and use a recrystallization solvent For recrystallization, the recrystallization solvent was 65% by volume of isopropanol and 35% by volume of water to obtain 47.54 g of phlorizin crystals (transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com