Water-based dye sublimation ink and preparation method thereof

A thermal sublimation and ink technology, applied in ink, dyeing method, transfer printing method, etc., can solve the problems of light color, low color transfer rate, scratching print head and other problems of thermal transfer printing ink, achieve fast drying speed, wide applicability, The effect of less ink ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

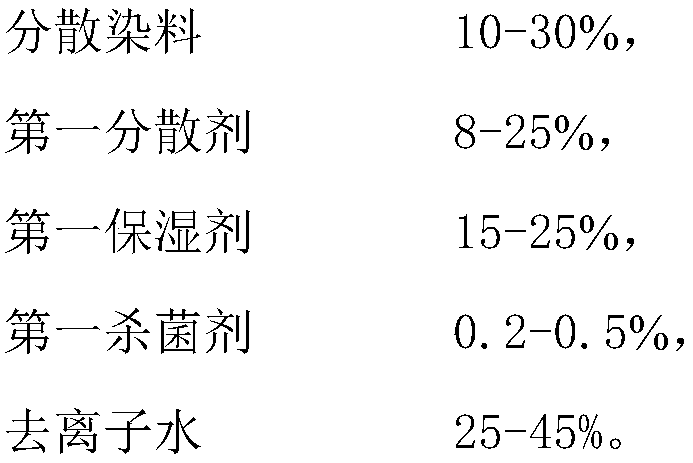

[0042] Disperse dye dispersions are made of the following components by weight percentage:

[0043] 30% disperse dyes;

[0044] 20% of the first dispersant (acrylic dispersant, modified polyether dispersant containing pigment affinity groups, polyacrylate dispersant, naphthalene sulfonic acid formaldehyde condensate, lignin dispersant and acetylene glycol Dispersant-like, the mass ratio is 1:1:1:1:1:1);

[0045] 20% of the first moisturizing agent (ethylene glycol, 1,2-propanediol, glycerol, polyethylene glycol 200, polyethylene glycol 400 and polyethylene glycol 600, the mass ratio is 1:1:1:1: 1:1);

[0046] 0.2% first fungicide (1,2-benzisothiazolin-3-one fungicide);

[0047] 29.8% deionized water.

[0048] Among them, disperse dyes can be selected according to the actual color needs, including yellow varieties of C.I. Disperse Yellow 34, 50, 54, 56, 60, 64, 114; red varieties of C.I. Disperse Red 5, 60, 75, 121, 146, 179, 189, 202; blue varieties are C.I. Disperse Blue...

Embodiment 2

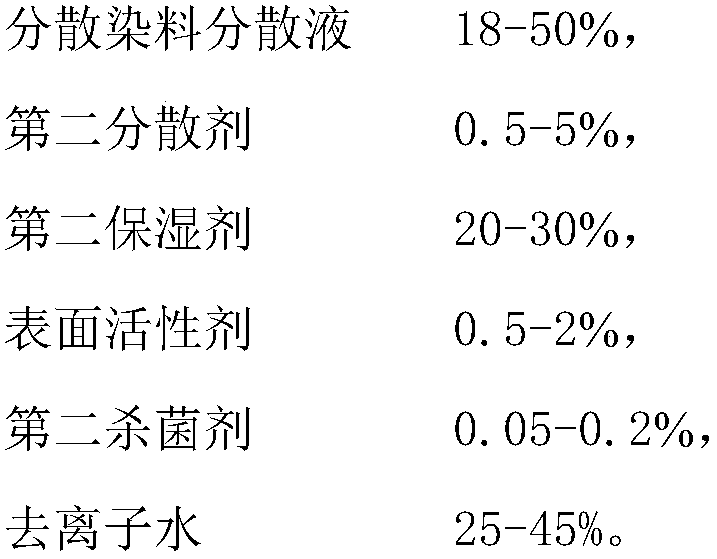

[0051] Disperse dye dispersions are made of the following components by weight percentage:

[0052] 20% disperse dyes;

[0053] 25% of the first dispersant (modified polyether dispersant, polyacrylate dispersant, lignin dispersant and acetylene glycol dispersant containing pigment affinity groups, the mass ratio is 1:1:2: 1);

[0054] 25% of the first moisturizing agent (polyethylene glycol 600, 1,4-butanediol, 1,2-pentanediol and diethylene glycol, the mass ratio is 1:1:2:2);

[0055] 0.5% first fungicide (1,2-benzisothiazolin-3-one fungicide);

[0056] 29.5% deionized water.

[0057] Among them, disperse dyes can be selected according to the actual color needs, including yellow varieties of C.I. Disperse Yellow 34, 50, 54, 56, 60, 64, 114; red varieties of C.I. Disperse Red 5, 60, 75, 121, 146, 179, 189, 202; blue varieties are C.I. Disperse Blue 3, 43, 54, 56, 60, 83, 96, 165, 295, 359, 360; black varieties are C.I. Disperse Blue 72, Disperse Blue 359, Disperse Blue 360, ...

Embodiment 3

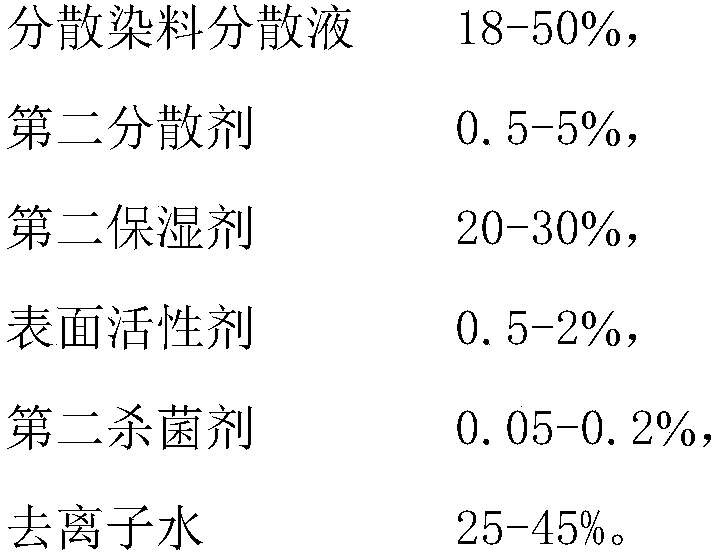

[0060] Disperse dye dispersions are made of the following components by weight percentage:

[0061] 16% disperse dyes;

[0062] 23% of the first dispersant (macromolecule block copolymer type dispersant containing pigment affinity group, acetylenic glycol type dispersant, surfactant type dispersant and naphthalene series sulfonic acid formaldehyde condensate, the mass ratio is 1 :1:2:3);

[0063] 24% the first moisturizing agent (diethylene glycol and triethylene glycol, the mass ratio is 1:1);

[0064] 0.3% first fungicide (1,2-benzisothiazolin-3-one fungicide);

[0065] 36.7% deionized water.

[0066] Among them, disperse dyes can be selected according to the actual color needs, including yellow varieties of C.I. Disperse Yellow 34, 50, 54, 56, 60, 64, 114; red varieties of C.I. Disperse Red 5, 60, 75, 121, 146, 179, 189, 202; blue varieties are C.I. Disperse Blue 3, 43, 54, 56, 60, 83, 96, 165, 295, 359, 360; black varieties are C.I. Disperse Blue 72, Disperse Blue 359,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com