Water-based nanometer hydraulic fluid based on particle surface treatment, preparation method and application thereof

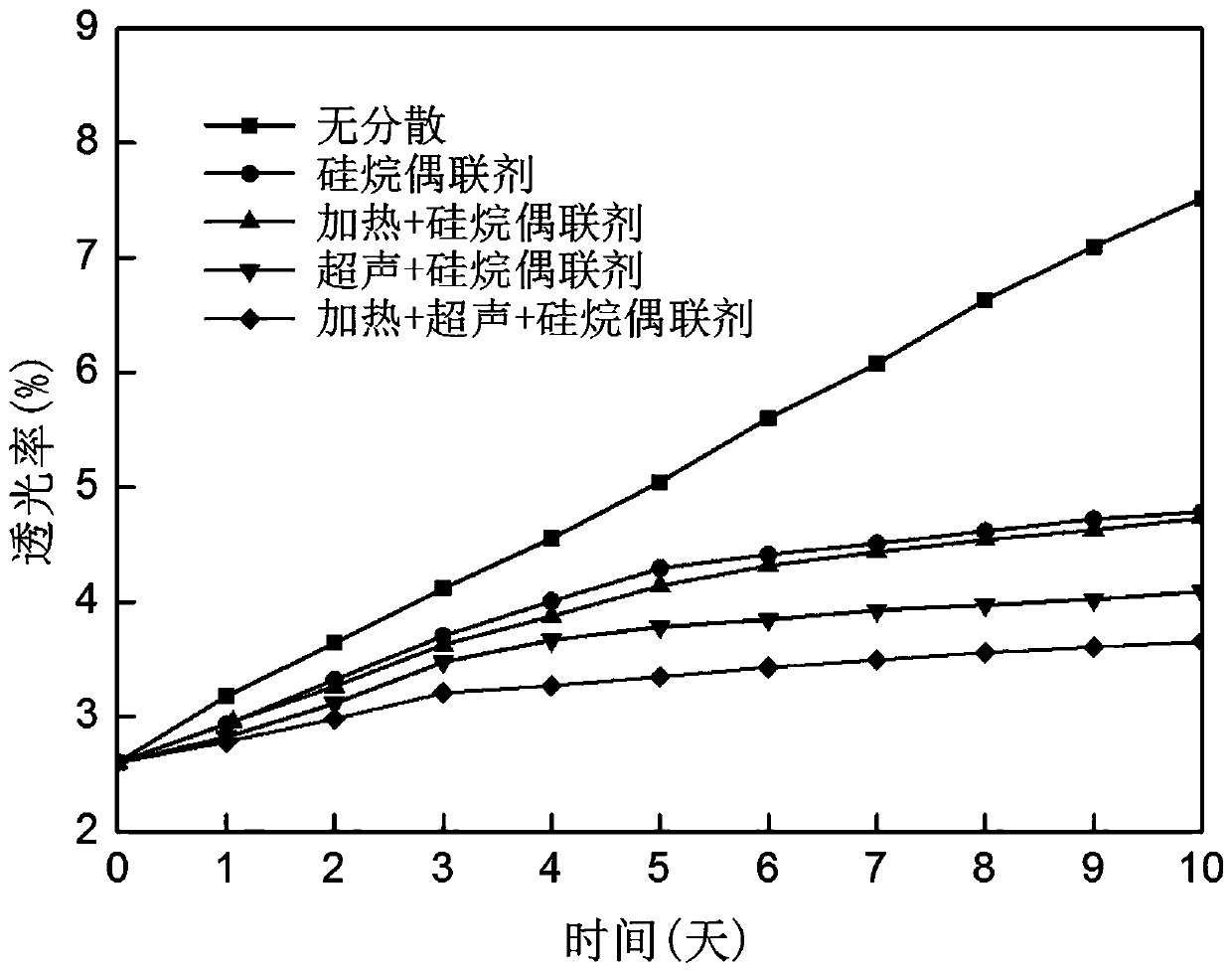

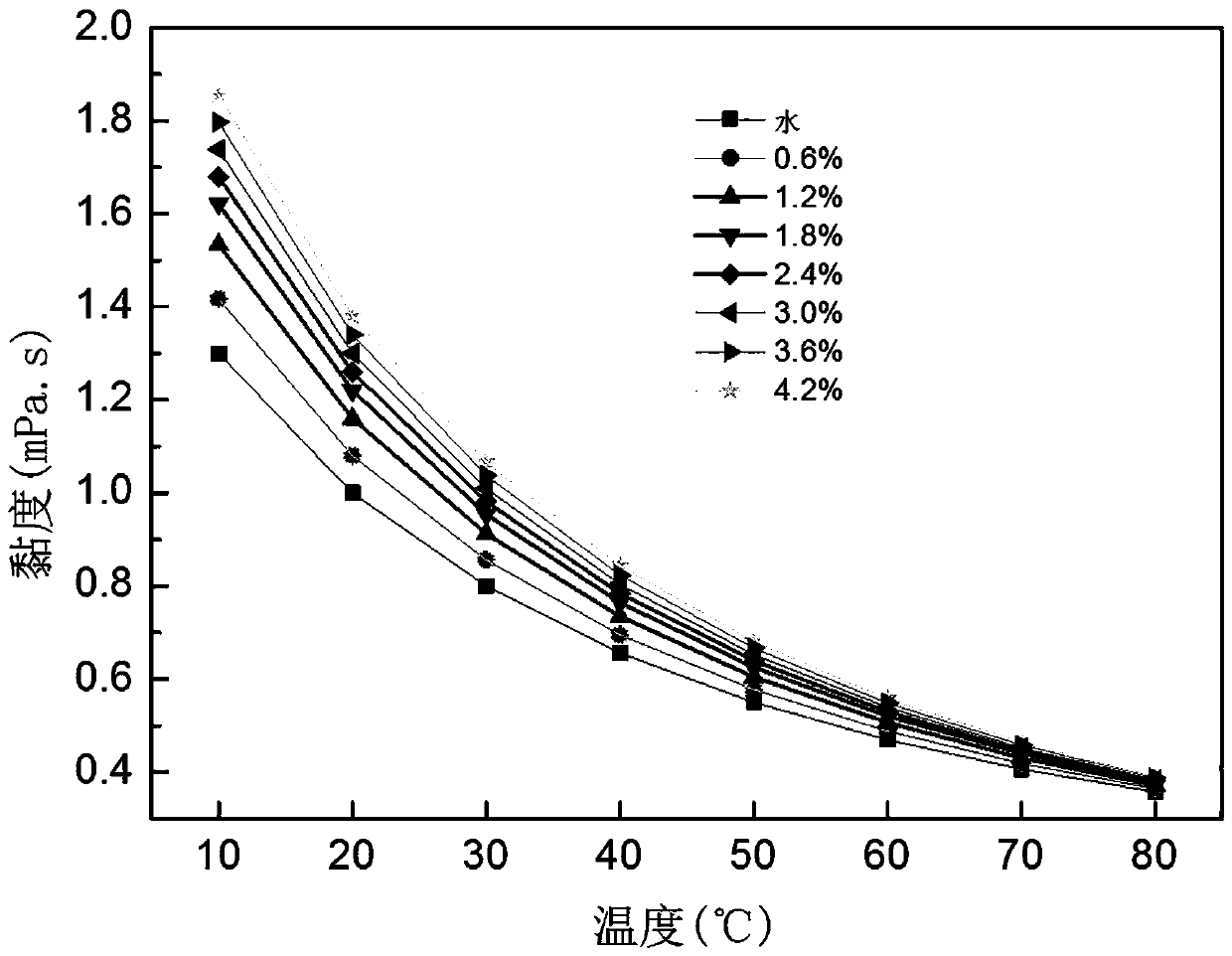

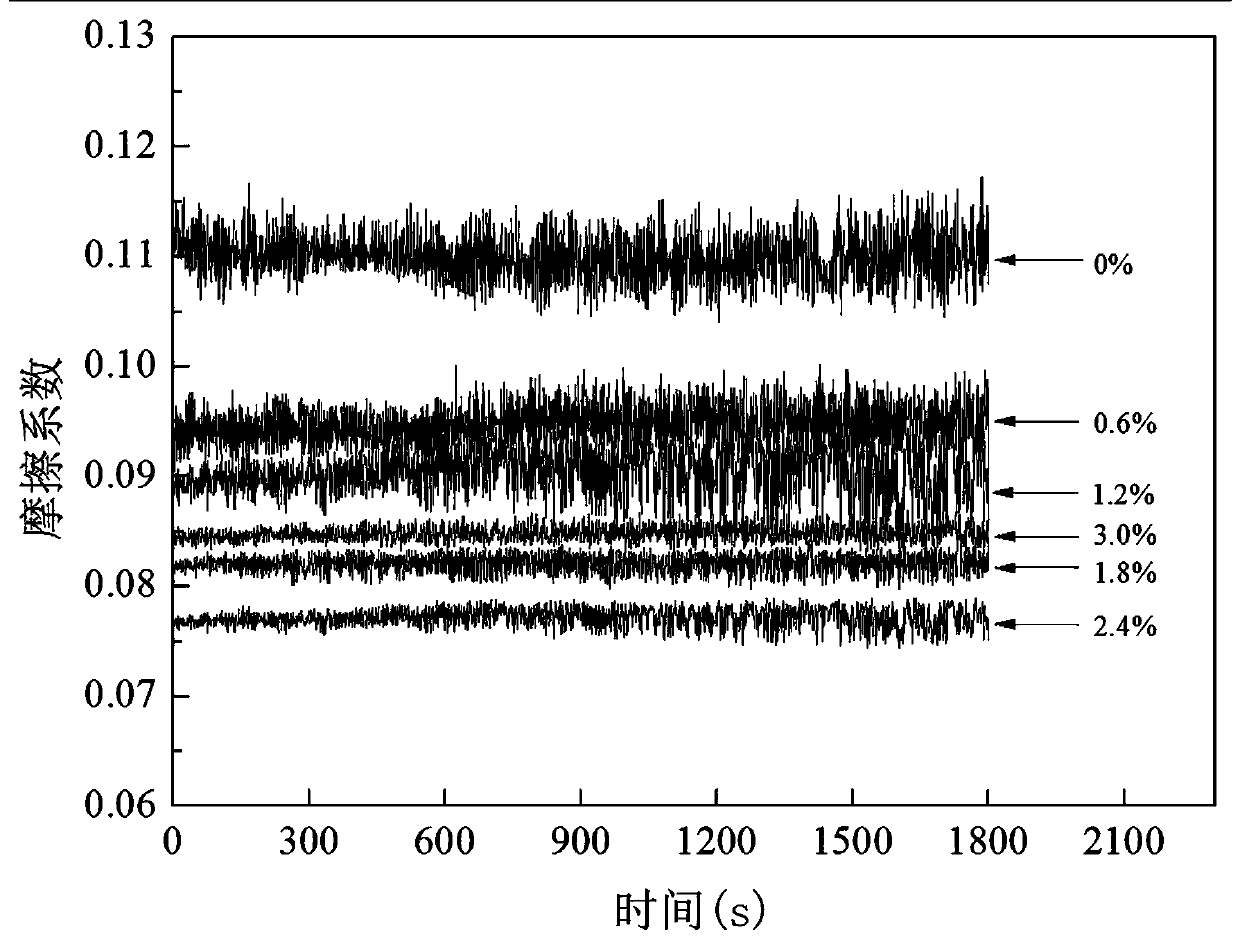

A particle surface, surface modification nanotechnology, applied in dyeing organosilicon compound treatment, petroleum industry, additives and other directions, can solve problems such as poor stability of water-based nano hydraulic fluid, reduce precipitation, solve poor stability, and have wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the water-based nano-hydraulic fluid comprises the following steps: the preparation of a silane solution, which uses 3-(2,3-glycidoxy)propyltrimethoxysilane and distilled water to prepare the silane solution, and dilute Hydrochloric acid and dilute sodium hydroxide to adjust the pH, first adjust the pH of the solution to 2 with dilute hydrochloric acid, and the environment with a pH of 2 is conducive to the hydrolysis of 3-(2,3-glycidoxy)propyltrimethoxysilane in water , greater than 2 or less than 2 will have a certain impact on the hydrolysis of 3-(2,3-epoxypropoxy)propyltrimethoxysilane, that is to say, PH is 2 is 3-(2,3-epoxy Propoxy) Propyltrimethoxysilane hydrolysis optimal conditions, then utilize dilute sodium hydroxide solution to adjust the pH of the solution to 10, and stir vigorously, the stirring speed is 600 ~ 700r / min, preferably stirring 5 under 700r / min hours, the silane solution is prepared, and the mass fraction of 3-(2,3-gly...

Embodiment 1

[0049] The first step: mix 23.7g of 3-(2,3-epoxypropoxy)propyltrimethoxysilane with 1000g of distilled water, and titrate the pH value of the solution with HCl until the pH value is 2. / min was stirred for 5 hours, then the pH value of the solution was adjusted to 10 with NaOH solution;

[0050] Step 2: Mix 25.7g of silica nanoparticles with 1000g of distilled water, and ultrasonically disperse for 10 hours to make an aqueous solution of nanoparticles;

[0051] Step 3: Add the silane solution prepared in the first step dropwise to the nanoparticle aqueous solution prepared in the second step, heat and homogenize the mixed solution, and then perform dialysis treatment, freezing treatment, and suction and freeze-drying treatment in sequence to prepare Obtain surface-modified nanoparticles, wherein the mass ratio of silane solution to nanoparticle aqueous solution is 1:4;

[0052] Among them, the heat homogenization treatment is to ultrasonically stir the solution for 48 hours i...

Embodiment 2

[0055] The first step: mix 25g of 3-(2,3-glycidyloxy)propyltrimethoxysilane with 1000g of distilled water, and titrate the pH value of the solution with HCl until the pH value is 2. Min was stirred for 5 hours, then the pH value of the solution was adjusted to 10 with NaOH solution;

[0056] Step 2: Mix 27g of silica nanoparticles with 1000g of distilled water, and ultrasonically disperse for 10 hours to make an aqueous solution of nanoparticles;

[0057] Step 3: Add the silane solution prepared in the first step dropwise to the nanoparticle aqueous solution prepared in the second step, heat and homogenize the mixed solution, and then perform dialysis treatment, freezing treatment, and suction and freeze-drying treatment in sequence to prepare Obtain surface-modified nanoparticles, wherein the mass ratio of silane solution to nanoparticle aqueous solution is 1:3.8;

[0058] Among them, the heat homogenization treatment is to ultrasonically stir the solution for 45 hours in an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wear scar diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com