Orientation nanofiber and preparing method thereof

A nanofiber, orientation technology, applied in fiber processing, stretch spinning, textile and papermaking, etc., can solve the problems of potential safety hazards, maximum adjustable strength limit, low safety factor, etc., to improve spinning fluency and Effects of production efficiency, improved orderliness, and spinning process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

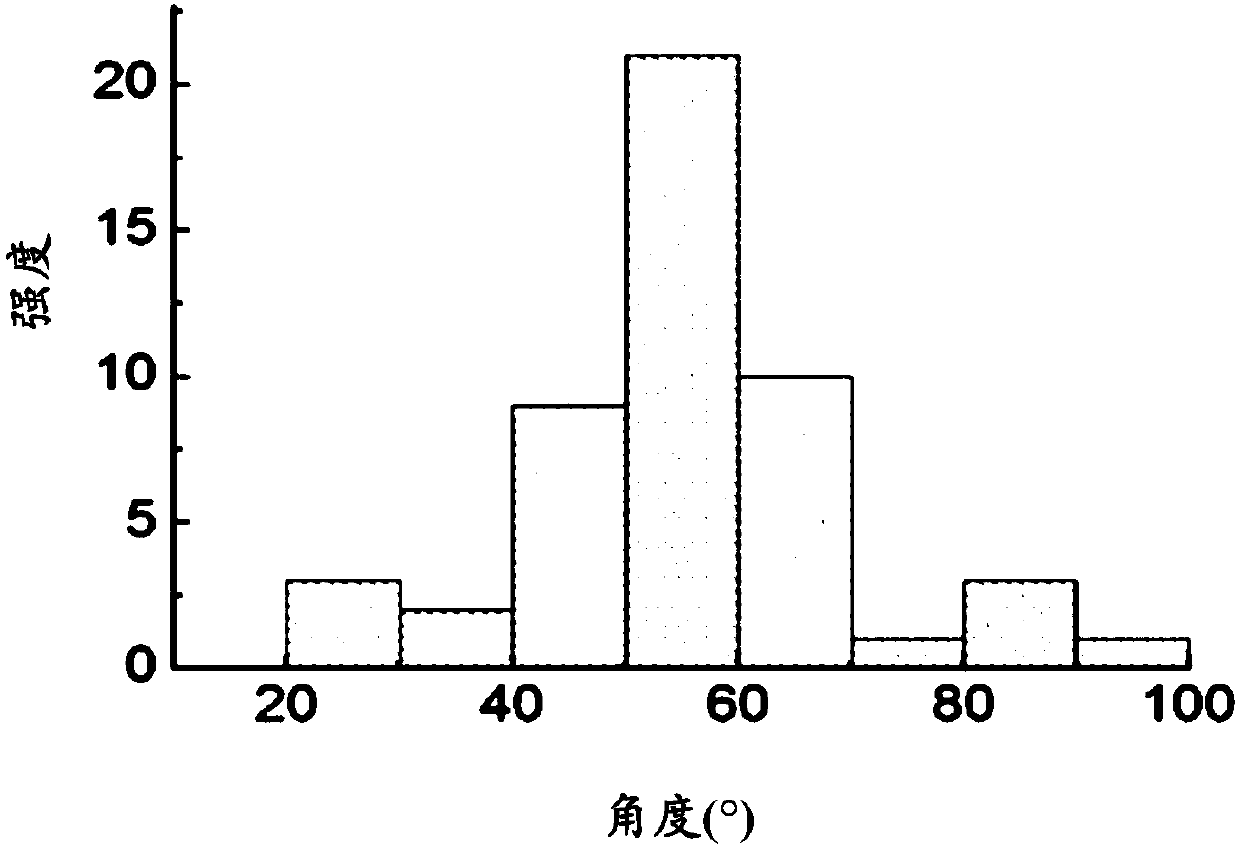

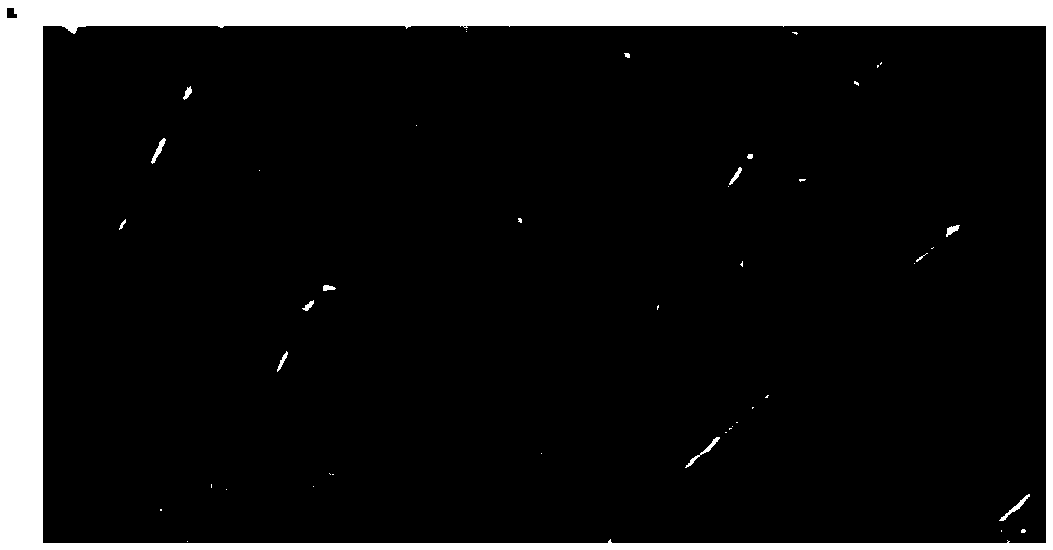

[0028] An embodiment of the preparation method of the oriented nanofiber of the present invention, the preparation method of the oriented nanofiber described in this embodiment is:

[0029] Polylactic acid is dissolved in methylene chloride, and the concentration of polylactic acid in the polylactic acid solution obtained is 4w / v%; the Fe 3 o 4 Nanoparticles were added to the prepared polylactic acid solution, and the Fe 3 o 4 Evenly dispersed in the polylactic acid solution to form a spinning solution, Fe 3 o 4 The mass fraction of nanoparticles in the spinning solution is 5%; the spinning solution is placed in an external magnetic field, and gas is injected into the spinning solution. The flow rate of the gas is 10m / s. In the external magnetic field, the bubbles burst to generate a jet, the jet stretches and deforms, the residual methylene chloride volatilizes, and solidifies to form oriented nanofibers; vacuum drying for 48 hours obtains the final oriented nanofibers. ...

Embodiment 2

[0031] An embodiment of the preparation method of the oriented nanofiber of the present invention, the preparation method of the oriented nanofiber described in this embodiment is:

[0032] Polycaprolactone is dissolved in dimethyl sulfoxide, and the polycaprolactone concentration in the gained polycaprolactone solution is 8w / v%; Gamma-Fe 2 o 3 The nanoparticles were added to the prepared polycaprolactone solution, and the γ-Fe 2 o 3 The nanoparticles are uniformly dispersed in the polycaprolactone solution to form a spinning solution, γ-Fe 2 o 3 The mass fraction of nanoparticles in the spinning solution is 5%; the spinning solution is placed in an external magnetic field, and gas is injected into the spinning solution, and the flow rate of the gas is 50m / s. In the external magnetic field, the bubbles burst to generate a jet, the jet stretches and deforms, the residual dimethyl sulfoxide volatilizes, and solidifies to form oriented nanofibers; vacuum drying for 48 hours o...

Embodiment 3

[0034] An embodiment of the preparation method of the oriented nanofiber of the present invention, the preparation method of the oriented nanofiber described in this embodiment is:

[0035] Polyethylene lactide was dissolved in trifluoroethanol, and the polyethylene lactide concentration in the obtained polyethylene lactide solution was 12w / v%; nickel nanoparticles were added to the prepared polyethylene lactide solution, and the The homogenizer uniformly disperses the nickel magnetic nanoparticles in the polyethylene lactide solution to form a spinning solution, the mass fraction of the nickel magnetic nanoparticles in the spinning solution is 5%; the spinning solution is placed in an external magnetic field, and Inject gas into the spinning solution, the flow rate of the gas is 100m / s, disturb the spinning solution to generate bubbles, in the external magnetic field, the bubbles burst to generate jets, the jets are stretched and deformed, and the residual trifluoroethanol vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com