A method for eliminating chemical groups on the surface of supercapacitor carbon

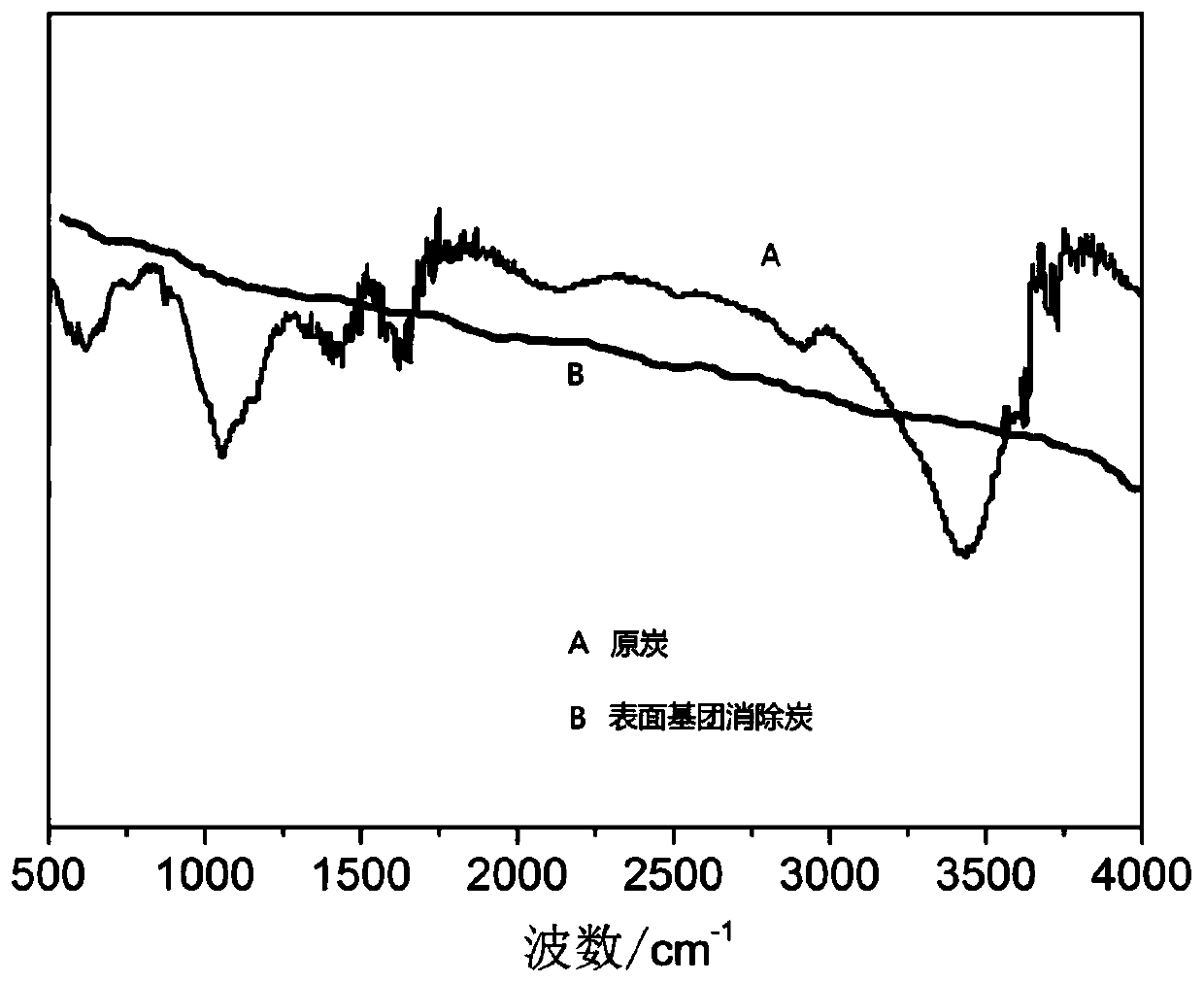

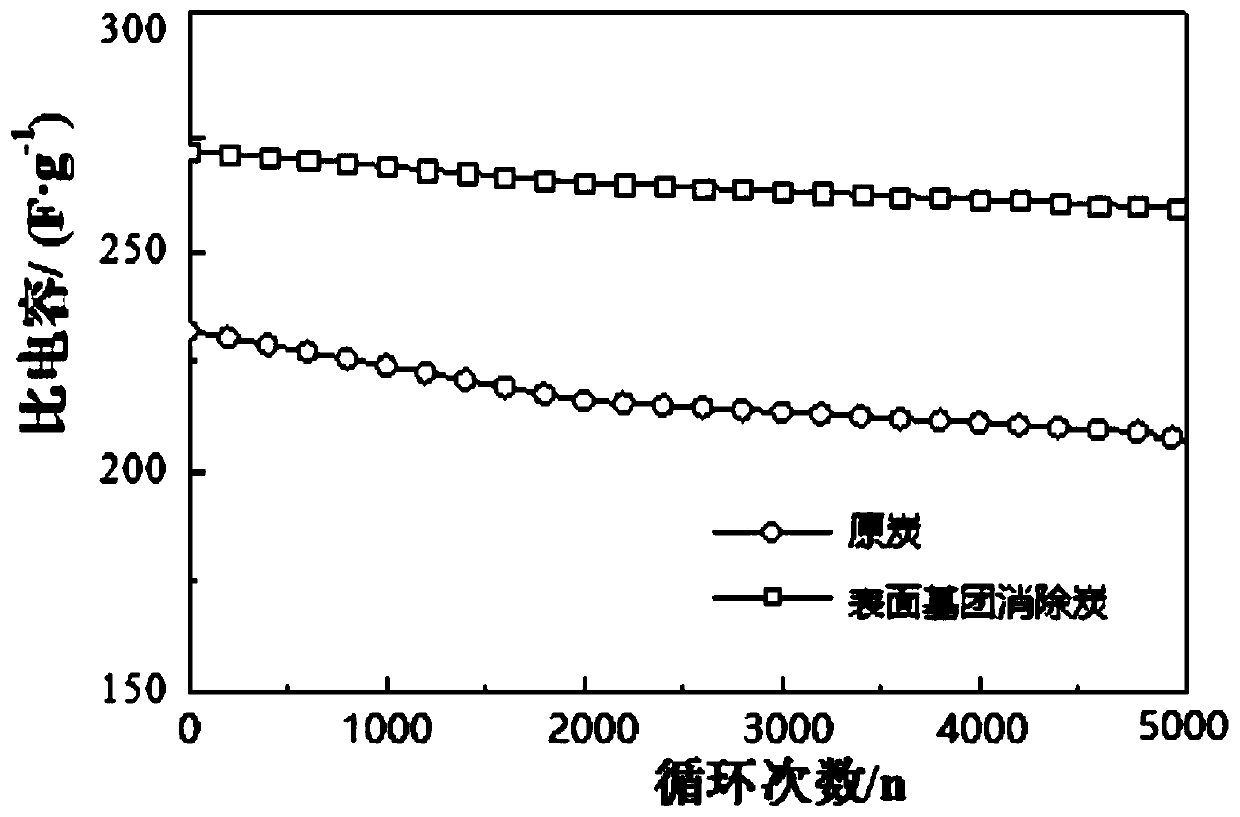

A technology of surface chemistry and capacitive carbon, which is applied in the field of elimination of surface chemical groups, can solve the problems of reduced specific surface area and electrochemical performance, poor treatment effect, high price of hydrazine hydrate, etc., and achieves easy promotion, low cost and high removal efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

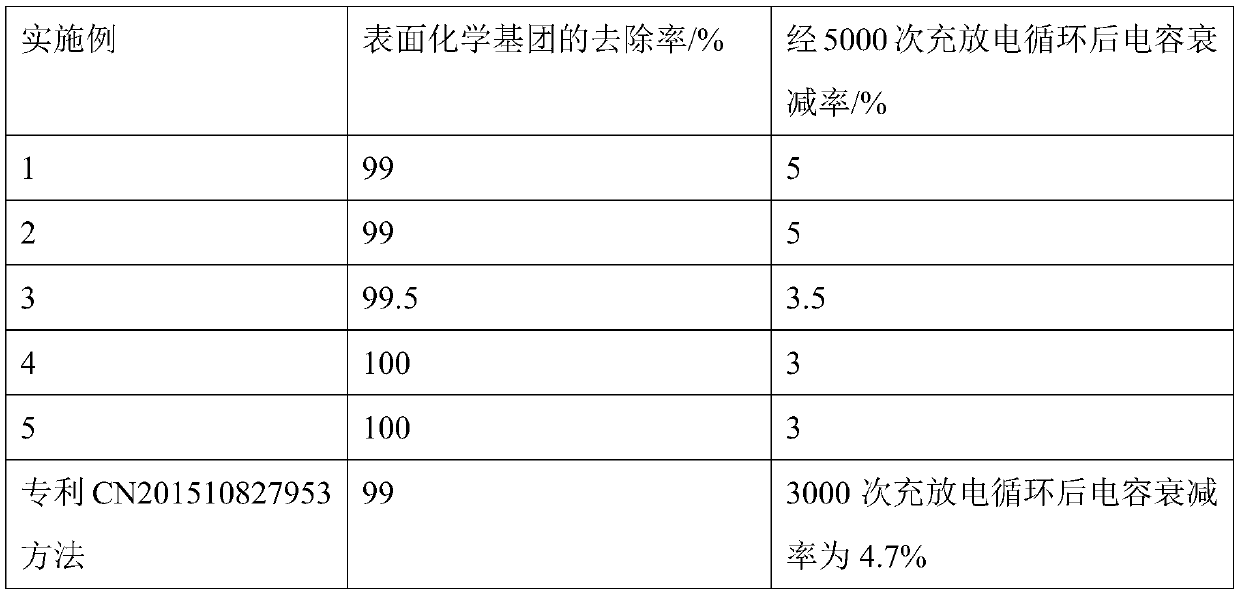

Examples

Embodiment 1

[0027] (1) supercapacitor carbon powder is crossed 800 mesh sieves, takes by weighing 50g, and hydroquinone is dissolved in water and makes the hydroquinone solution that mass concentration is 5%;

[0028] (2) Dissolve the supercapacitor carbon powder in the hydroquinone solution obtained in step (1) at a mass volume ratio of 1:20, then reflux in the water bath, keep the carbon powder in suspension under magnetic stirring at 2000r / min, and heat it in a water bath at 60°C After 3 hours, filter after the reaction, and further wash the obtained carbon powder with deionized water, dry it at 100°C for 2.5 hours, and take it out to obtain a supercapacitor carbon that eliminates surface functional groups.

Embodiment 2

[0030] (1) Supercapacitor carbon powder is passed through an 800 mesh sieve, and 50g is weighed, and hydroquinone is dissolved in water to obtain a hydroquinone solution with a mass concentration of 10%;

[0031] (2) Dissolve the supercapacitor carbon powder in the hydroquinone solution obtained in step (1) at a mass volume ratio of 1:20, then reflux in the water bath, keep the carbon powder in suspension under magnetic stirring at 2000r / min, and heat it in a water bath at 60°C After 6 hours, filter after the reaction, and further wash the obtained carbon powder with deionized water, dry it at 100°C for 3 hours, and take it out to obtain a supercapacitor carbon that eliminates surface functional groups.

Embodiment 3

[0033] (1) Supercapacitor carbon powder is passed through an 800 mesh sieve, and 50g is weighed, and hydroquinone is dissolved in water to obtain a hydroquinone solution with a mass concentration of 15%;

[0034] (2) Dissolve the supercapacitor carbon powder in the hydroquinone solution obtained in step (1) according to the mass volume ratio of 1:20, then reflux in the water bath, keep the carbon powder in suspension under magnetic stirring at 2000r / min, and heat it in a water bath at 90°C After 9 hours, filter after the reaction, and further wash the obtained carbon powder with deionized water, dry it at 100°C for 3.5 hours, and take it out to obtain a supercapacitor carbon that eliminates surface functional groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com