Preparation and application of a conditioner capable of remediating heavy metal-contaminated soil

A soil conditioner and a technology for polluted soil, applied in the field of soil remediation and soil improvement, can solve the problems of inability to improve soil, only passivate heavy metals, unstable effect, etc., achieve enhanced neutralization ability, good adsorption performance, and avoid attack Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

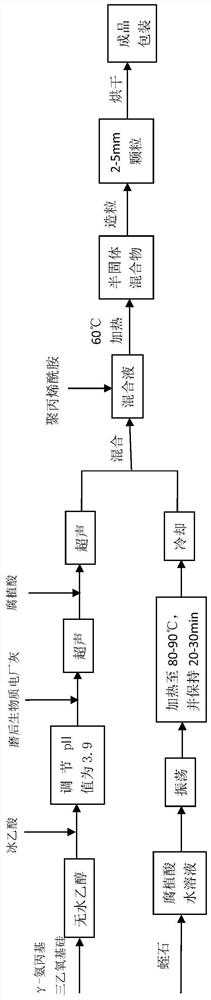

Method used

Image

Examples

Embodiment 1

[0032] A soil conditioner capable of repairing heavy metal-contaminated soil, mainly composed of the following raw materials in parts by weight: 400 parts of biomass power plant ash, 20 parts of vermiculite with a thermal expansion ratio of more than 8 times, and water-soluble 18 parts of humic acid, 8 parts of gamma-aminopropyl triethoxysilane with a purity greater than 95%, 1 part of polyacrylamide with a purity greater than 80% and 90 parts of absolute ethanol with a purity greater than 99%. The above raw materials are taken according to the quantity by weight, and the preparation process comprises the following steps:

[0033] A. Use a ball mill or a Raymond mill to pulverize the biomass power plant ash to a particle size of 0.002mm, and set aside;

[0034] B. Mix vermiculite with a particle size of less than 2mm and a humic acid aqueous solution with a mass fraction of 7% in a mass ratio of 1:10, shake for 20 hours, then heat the mixed system to 80 degrees Celsius, keep i...

Embodiment 2

[0039]A soil conditioner capable of repairing heavy metal-contaminated soil, mainly composed of the following raw materials in parts by weight: 600 parts of biomass power plant ash, 30 parts of vermiculite with a thermal expansion ratio of more than 8 times, and water-soluble 25 parts of humic acid, 13 parts of gamma-aminopropyltriethoxysilane with a purity greater than 95%, 5 parts of polyacrylamide with a purity greater than 80%, and 120 parts of absolute ethanol with a purity greater than 99%. The above raw materials are taken according to the quantity by weight, and the preparation process comprises the following steps:

[0040] A. Use a ball mill or a Raymond mill to pulverize the biomass power plant ash until the particle size is less than 0.075mm, and set aside;

[0041] B. Mix the vermiculite with a particle size of less than 2mm and the humic acid aqueous solution with a mass fraction of 7% in a mass ratio of 1:15, shake for 30 hours, then heat the mixed system to 90 ...

Embodiment 3

[0046] A soil conditioner capable of repairing heavy metal-contaminated soil, mainly composed of the following raw materials in parts by weight: 500 parts of biomass power plant ash, 25 parts of vermiculite with a thermal expansion ratio of more than 8 times, and water-soluble 20 parts of humic acid, 10 parts of gamma-aminopropyltriethoxysilane with a purity greater than 95%, 3 parts of polyacrylamide with a purity greater than 80% and 100 parts of absolute ethanol with a purity greater than 99%. The above raw materials are taken according to the quantity by weight, and the preparation process comprises the following steps:

[0047] A. Use ball mill or Raymond mill to pulverize the biomass power plant ash to a particle size of 0.055 mm, and set aside;

[0048] B. Mix the vermiculite with a particle size of less than 2mm and the humic acid aqueous solution with a mass fraction of 7% in a mass ratio of 1:12, shake for 25 hours, then heat the mixed system to 85 degrees Celsius, k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com