AlCrSiN/VSiN multi-layer nano-coating and preparation method thereof

A nano-multilayer and coating technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of poor bonding force, large friction coefficient, and decreased hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing an AlCrSiN / VSiN nanometer multilayer coating, comprising the following steps:

[0040] a) Depositing Al on the substrate surface using cathodic arc evaporation 50 Cr 50 N transition layer;

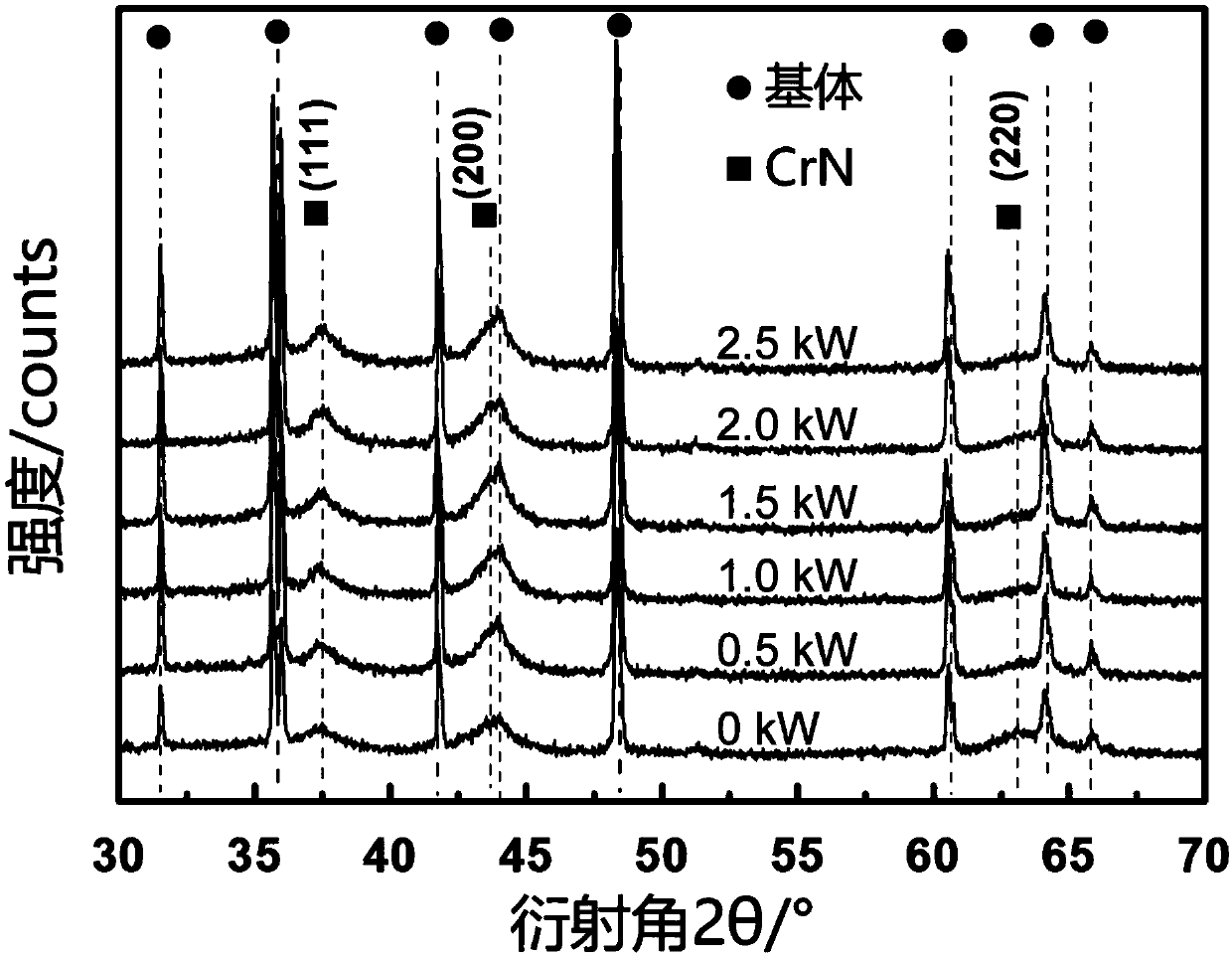

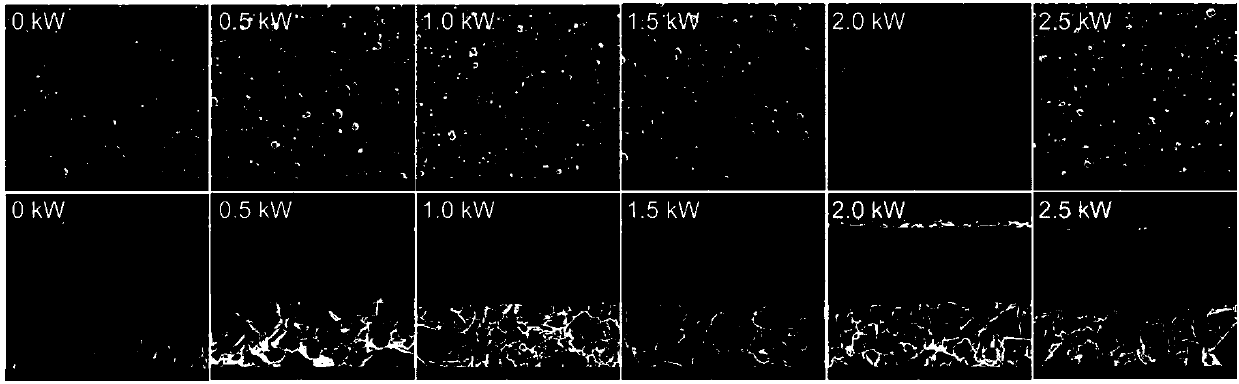

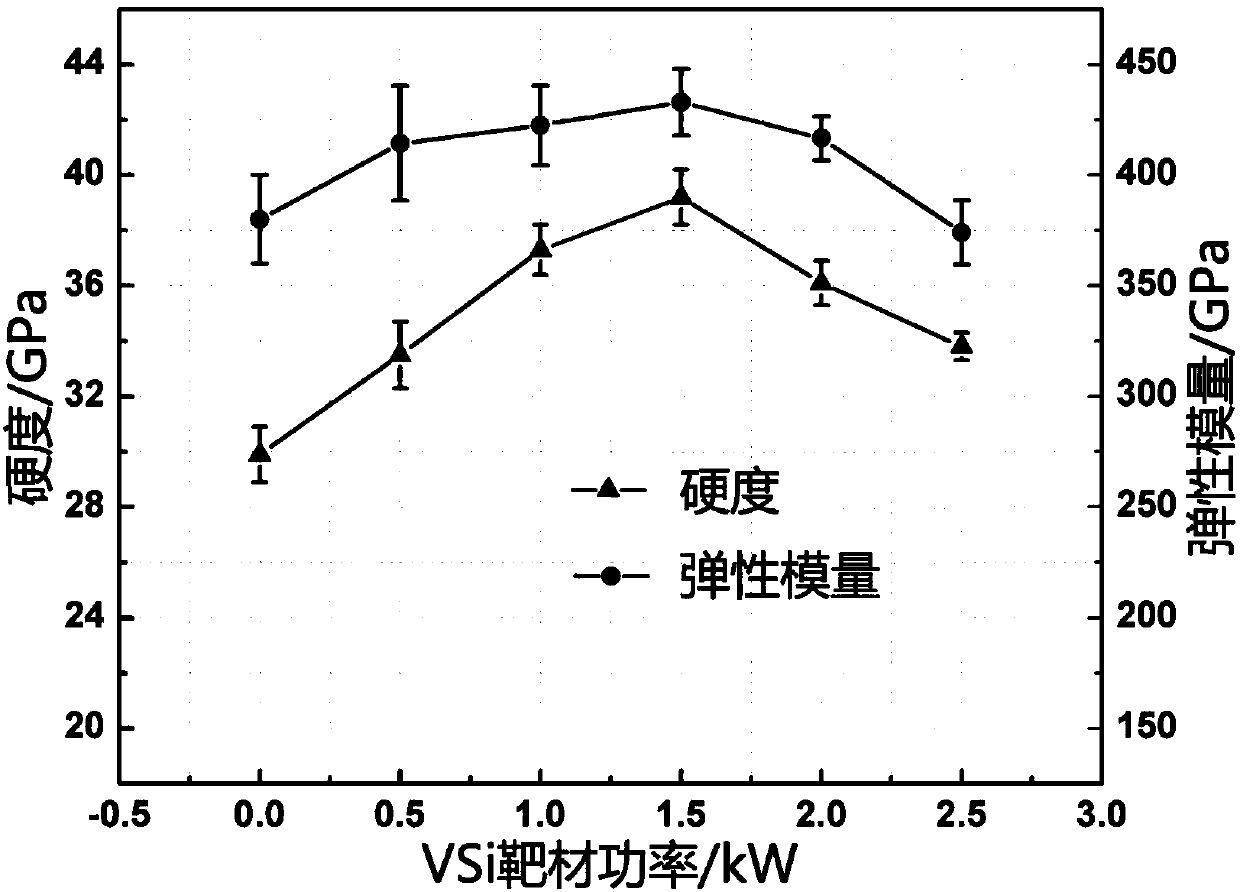

[0041] b) Using a high-power pulsed magnetron power supply to sputter the VSi target, and using a DC arc power supply to evaporate the AlCrSi target at the cathode, in Ar gas and N 2 AlCrSiN / VSiN nanometer multi-layer coatings were reactively deposited in a mixed atmosphere of gas.

[0042] The present invention first uses cathodic arc evaporation to deposit Al on the surface of the substrate 50 Cr 50 N transition layer. In the present invention, there is no special limitation on the type and source of the substrate, and a cemented carbide substrate well known to those skilled in the art can be used. In a preferred embodiment of the present invention, the substrate is a WC-Co cemented carbide substrate.

[0043] In the present inv...

Embodiment 1

[0076] (1) Substrate pretreatment:

[0077] After the substrate is mechanically ground and polished, it is cleaned with a solvent; the specific process of the solvent cleaning is as follows: first use isopropanol to ultrasonically clean for 10 minutes, then use 98% alcohol solution to ultrasonically clean for 10 minutes, and then use an ultrasonic Ultrasonic cleaning with pure water for 3 minutes; followed by ion source bombardment cleaning treatment: use Hall ion source to clean the substrate for 5 minutes to obtain the pretreated substrate; wherein, the ambient pressure of the ion source bombardment cleaning treatment is 2.2×10 -2 Pa, the Ar gas flow rate is 50 sccm, and the substrate bias voltage is -150V.

[0078] (2) Deposit Al on the pretreated substrate surface obtained in step (1) using cathodic arc evaporation 50 Cr 50 N transition layer:

[0079] Heat the working temperature of the deposition chamber to 350°C-400°C, heat the substrate to 400°C-450°C, and extract t...

Embodiment 2

[0083] (1) Substrate pretreatment:

[0084] With embodiment 1.

[0085] (2) Deposit Al on the pretreated substrate surface obtained in step (1) using cathodic arc evaporation 50 Cr 50 N transition layer:

[0086] With embodiment 1.

[0087] (3) Use a high-power pulsed magnetron power supply to sputter the VSi target, use a DC arc power supply to evaporate the AlCrSi target, and use Ar gas and N 2 Reactive deposition of AlCrSiN / VSiN nano-multilayer coating in a mixed atmosphere of gas:

[0088] in Al 50 Cr 50 After the deposition of the N transition layer is completed, maintain the temperature of the chamber at 350°C and the temperature of the substrate at 350°C to 400°C. 2 gas, adjust the flow rate so that Ar gas and N 2 The total gas flow is 80sccm~100sccm, N 2 The gas partial pressure ratio is 40% to 80%; adjust the deposition chamber pressure to 0.5Pa to 2.0Pa, open the VSi magnetron target and the AlCrSi arc target at the same time, the sputtering power of the VSi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com