Straw-steel composite prefabricated load-bearing wall and manufacturing method thereof

A prefabricated, load-bearing wall technology, applied in the direction of architecture, building components, building structures, etc., can solve the problems of insufficient comprehensive research results on composite walls, difficulties in connecting composite wall panels and steel structures, etc., and achieve strong overall structural performance, Reduce air pollution, good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

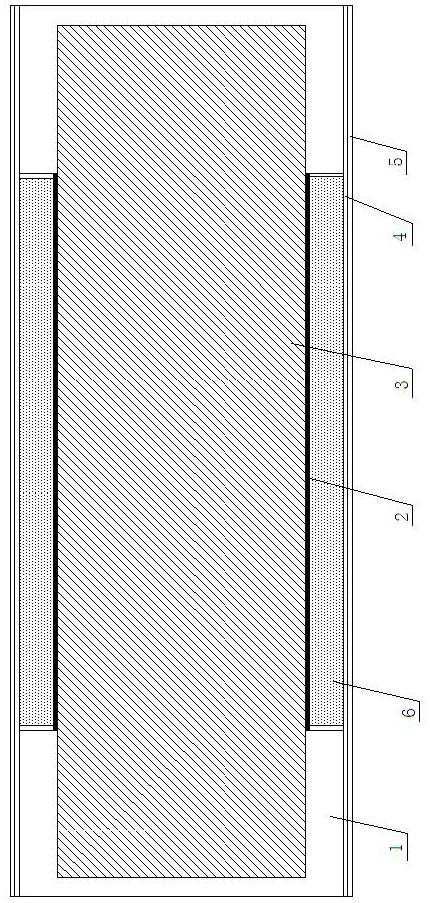

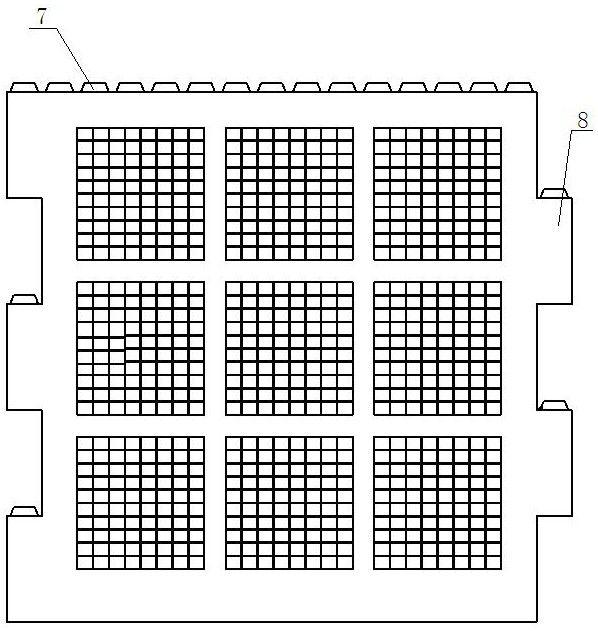

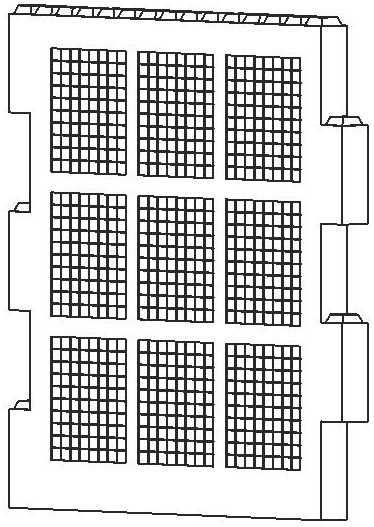

[0030]A straw-steel composite assembly-type load-bearing wall, which is composed of: a steel frame for assembling and assembling, the two inner walls of the steel frame are provided with steel wire meshes, and the space enclosed by the steel frame is filled with straw The upper and lower ends of the steel frame are provided with wall vertical interfaces for direct butting, and the left and right ends of the steel frame are provided with wall interfaces for staggered butting.

Embodiment 2

[0032]According to the straw-steel composite assembly type load-bearing wall described in embodiment 1, the steel frame is welded around the channel steel into a rectangular frame, and a grid formed by welding strip steel plates is welded to the flange of the channel steel. As the side of the steel frame; the flange of the channel steel is welded with a set of hooks, and the steel wire mesh is hung on the hooks close to the tic-shaped grid, so that the steel wire mesh can restrain and support the straw board, so that the straw The lateral load on the slab is evenly distributed;

[0033]The wall interface is a set of rectangular parallelepiped interfaces welded to the channel steel, the rectangular parallelepiped interface has an upper groove, a trapezoidal steel block is arranged in the upper groove, and a spring is arranged under the trapezoidal steel block. The rectangular parallelepiped interface also has a lower groove, when the wall interface is staggered butted, the trapezoidal s...

Embodiment 3

[0036]The above-mentioned straw-steel composite assembly-type load-bearing wall is made by welding light channel steel around the steel frame, the middle grid is welded by light steel plate, and the end of the straw board is inserted into the groove of the light channel steel In the middle, the groove of the channel steel must be equal to the thickness of the straw slab. The channel steel is specifically C-shaped steel; the C-shaped steel is sleeved around the straw slab and the C-shaped steel is welded together; the well-shaped grid is welded to the wing of the C-shaped steel. At the edge, the hook is connected to the steel frame in the form of welding. The two ends of the horizontal and vertical steel wires are respectively passed through the hook, the steel wire is tightened, and then the steel wire is passed through the hook part, folded back and twisted into the steel wire, so that the steel wire Fix it on the hook. During this process, prestress will be generated inside the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com