Preparation method of coal-based carbon fiber loaded palladium catalyst

A palladium catalyst, coal-based carbon technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high price and poor electrocatalytic stability of formic acid oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

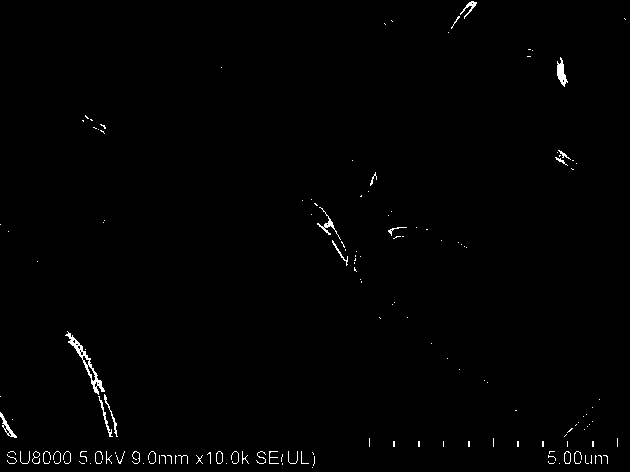

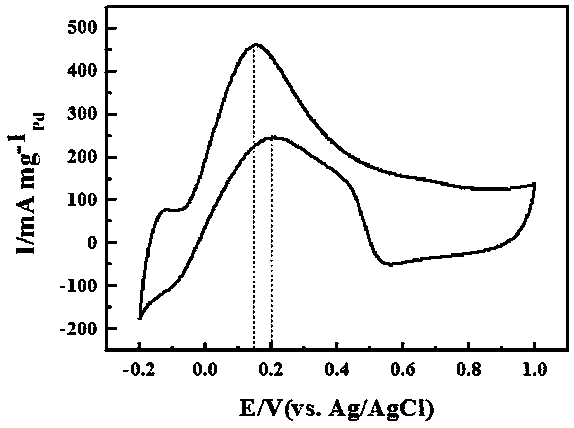

[0018] Put 10g of coal powder in an ice-water bath, add 240 mL of concentrated sulfuric acid:concentrated nitric acid=1:1 (volume ratio) mixture under stirring, let it stand for 48 hours, add 3L of water to dilute, then suction filter, wash, and dry to obtain oxidized Coal; then add 0.8g of oxidized coal into 10mL of N,N-dimethylformamide dissolved in 0.8g of polyacrylonitrile at 70°C, mix and stir overnight, then add it into the syringe, and put it into the syringe pump of the electrospinning machine above, spinning under the conditions of voltage 20 kV, spinning solution injection speed 0.9mL / h, and receiving distance 20cm to obtain precursor fiber non-woven fabric; then the precursor was raised to 1 °C / min at a heating rate of 280°C, heat preservation for 3 h for pre-oxidation, the pre-oxidized fibers were arranged in a high-temperature tube furnace with programmable temperature control, in N 2 In the atmosphere, the temperature was raised to 800 °C at a rate of 5 °C / min, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com