Preparation method of nano sulfur/nitrogen-doped titanium dioxide composite cathode material

A composite cathode material, titanium dioxide technology, applied in the direction of battery electrodes, electrical components, circuits, etc., to solve the volume expansion, improve cycle performance, enhance the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

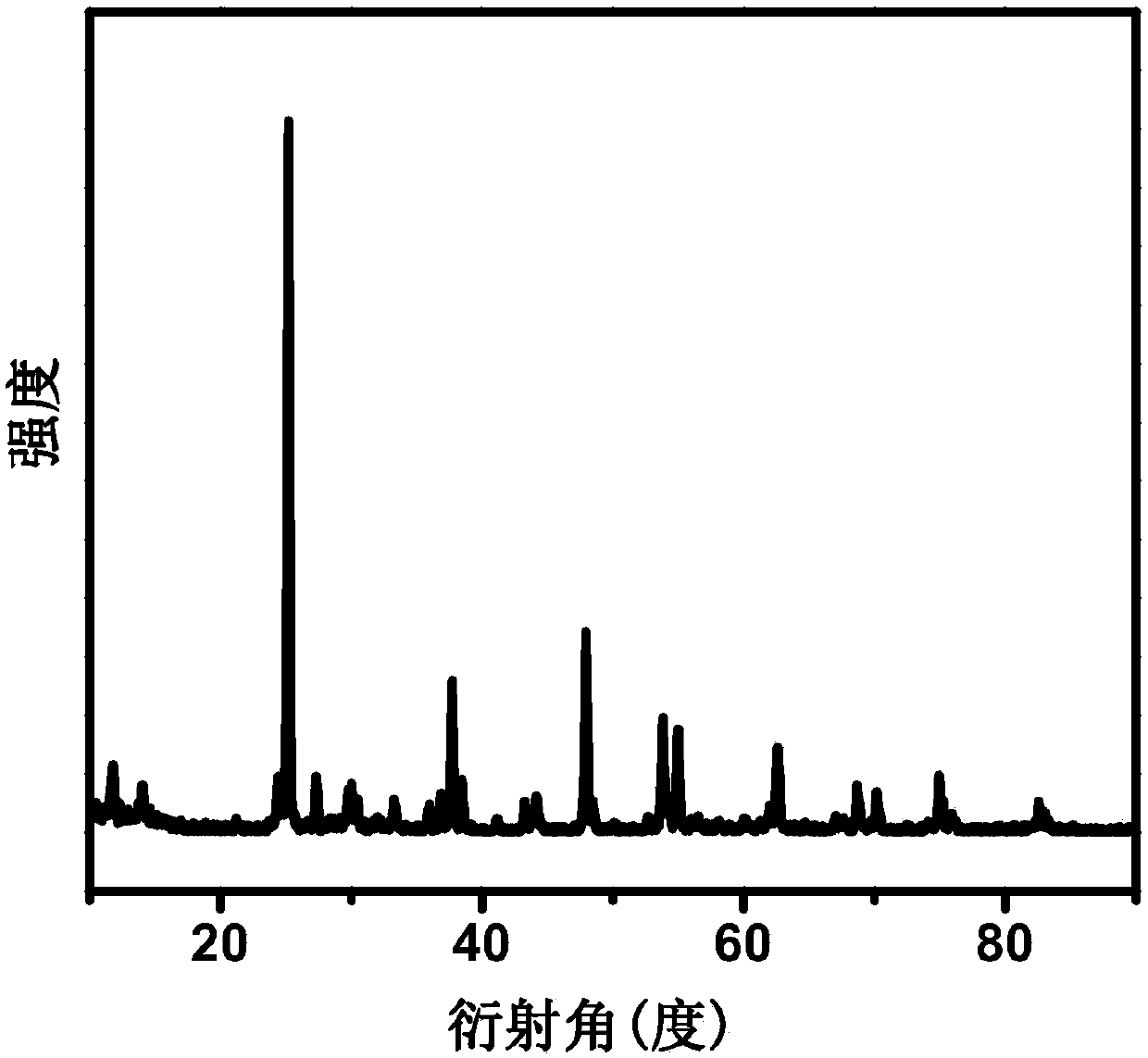

Embodiment 1

[0027] (1) Stir and mix 10 mL of tetrabutyl titanate and 10 mL of isopropanol evenly.

[0028] (2) 60mL (0.2M) of HNO 3 Mix well with 2mL of acetylacetone.

[0029] (3) Add the solution in (1) to (2) at a constant speed for 2 minutes, and stir for 10 hours in a water bath at 50° C. to obtain a nano-sol.

[0030] (4) Add 10mL of triethylamine and stir for 10h at room temperature, add 0.2M HNO 3 The pH value of the solution was adjusted to 7.

[0031] (5) The above solution was transferred into a high-pressure hydrothermal reaction kettle, kept at 120° C. for 12 hours, and then cooled to room temperature to obtain a nitrogen-doped titanium dioxide precipitate.

[0032] (6) Centrifuge the precipitate, wash it with absolute ethanol, and dry it in an oven at 90° C. to form a xerogel.

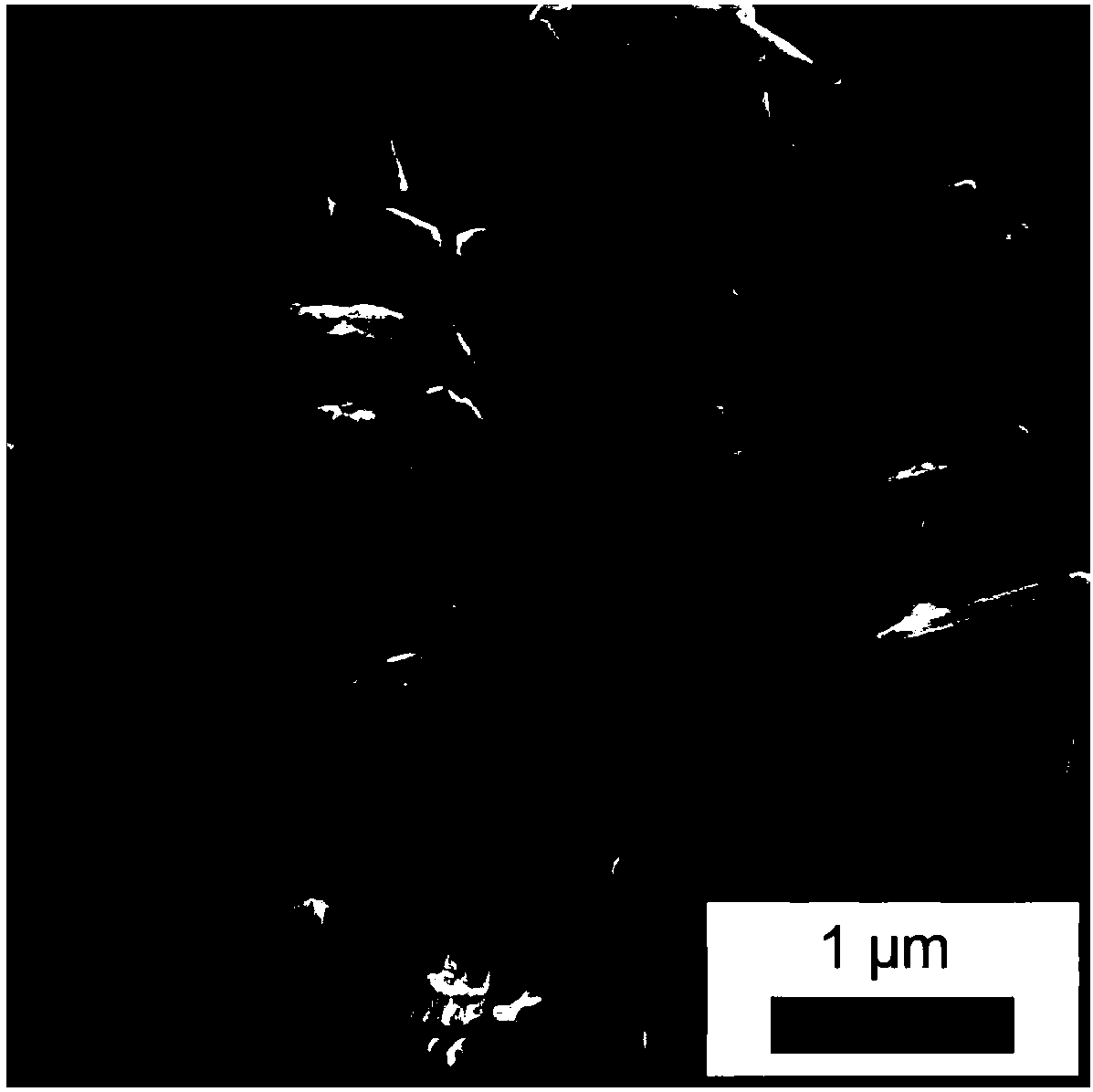

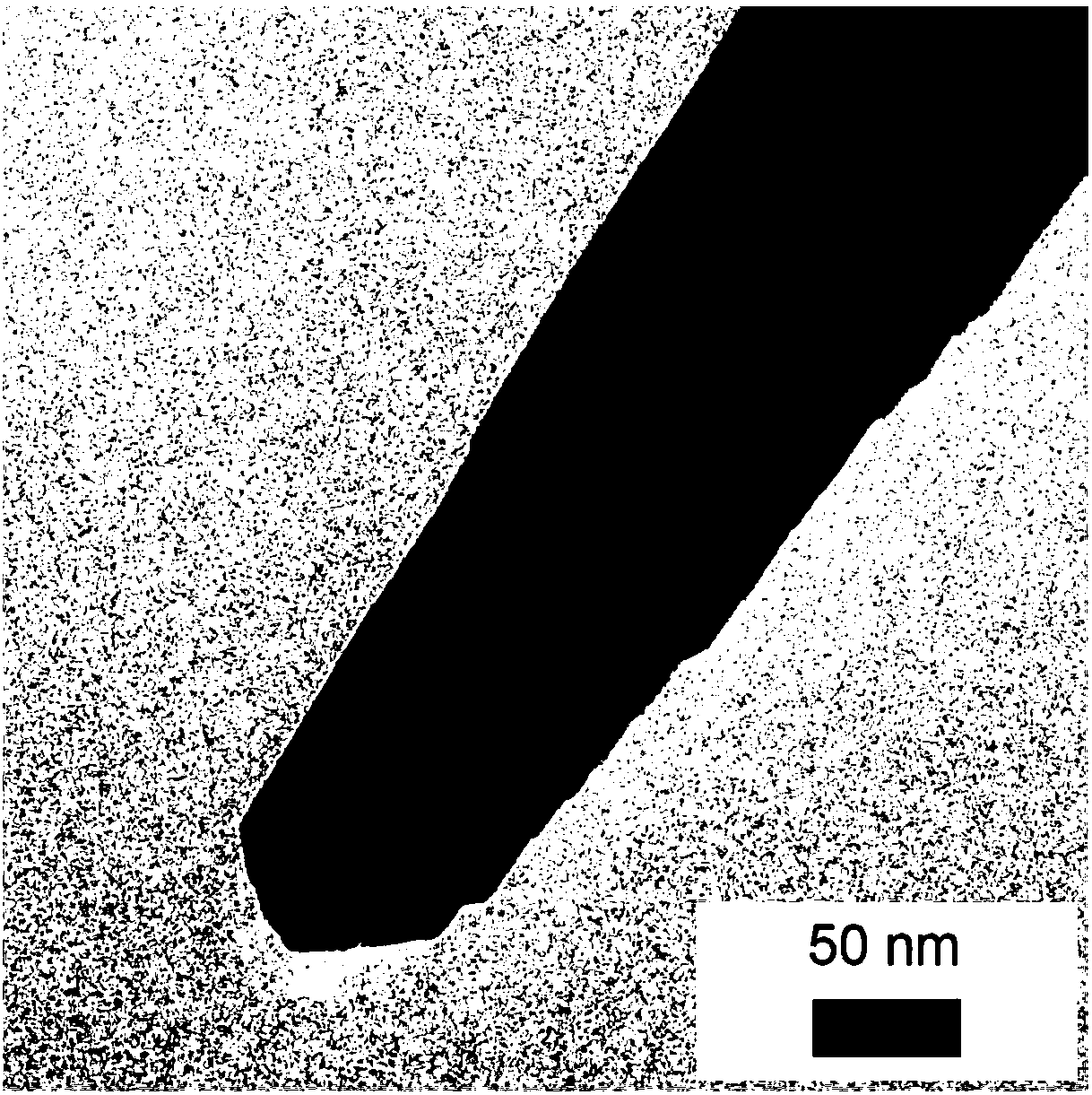

[0033] (7) Weigh the nano-sulfur powder and nitrogen-doped titanium dioxide in a mass ratio of 1:1, and add them to a steel ball mill tank for ball milling (mass ratio ball: material: ethanol = 4...

Embodiment 2

[0039] (1) Stir and mix 10 mL of tetrabutyl titanate and 10 mL of isopropanol evenly.

[0040] (2) 60mL (0.2M) of HNO 3 Mix well with 2mL of acetylacetone.

[0041] (3) Slowly add the solution in (1) to (2) (adding at a constant speed within 2 min), and stir for 10 h in a water bath at 50° C. to obtain a nano-sol.

[0042] (4) Add 10mL of triethylamine and stir for 10h at room temperature, add 0.2M HNO 3 The pH of the solution was adjusted to 10.

[0043] (5) The above solution was transferred into a high-pressure hydrothermal reaction kettle, kept at 120° C. for 12 hours, and then cooled to room temperature to obtain a nitrogen-doped titanium dioxide precipitate.

[0044] (6) Centrifuge the precipitate, wash it with absolute ethanol, and dry it in an oven at 90° C. to form a xerogel.

[0045] (7) Weigh the nano-sulfur powder and nitrogen-doped titanium dioxide in a mass ratio of 1:1, and add them to a steel ball mill tank for ball milling (mass ratio ball: material: ethan...

Embodiment 3

[0048] (1) Stir and mix 10 mL of tetrabutyl titanate and 10 mL of isopropanol evenly.

[0049] (2) 60mL (0.2M) of HNO 3 Mix well with 2mL of acetylacetone.

[0050] (3) Slowly add the solution in (1) to (2) (adding at a constant speed within 2 min), and stir for 10 h in a water bath at 50° C. to obtain a nano-sol.

[0051] (4) Add 10mL of triethylamine and stir for 10h at room temperature, add 0.2M HNO 3 Adjust the pH value of the solution to 3.

[0052] (5) The above solution was transferred into a high-pressure hydrothermal reaction kettle, kept at 120° C. for 12 hours, and then cooled to room temperature to obtain a nitrogen-doped titanium dioxide precipitate.

[0053] (6) Centrifuge the precipitate, wash it with absolute ethanol, and dry it in an oven at 90° C. to form a xerogel.

[0054] (7) Weigh the nano-sulfur powder and nitrogen-doped titanium dioxide in a mass ratio of 1:1, and add them to a steel ball mill tank for ball milling (mass ratio ball: material: ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com