High-specific-surface-area mesoporous methylsilsesquioxane aerogel block and preparation method thereof

A technology of mesoporous methyl silicon and sesquioxane, which is applied in ceramic products, other household appliances, applications, etc., can solve problems such as hidden safety hazards, flammability of petroleum ether, etc., and achieve the effect of high safety and reliability, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Add 0.24 g of cetyltrimethylammonium chloride to 6 mL with a concentration of 5*10 -4 mol•L -1 In the hydrochloric acid solution, stir to dissolve, then add 3 mL of precursor methyltrimethoxysilane (MTMS), stir magnetically for 60 min under sealed conditions, then add 1.0 mL of 1,2-propylene oxide (PO), stir for 1 ~2 min, put in 40 o Aging in C oven for 2 to 3 days;

[0036] 2) The gel formed in step 1) was subjected to three solvent replacements with isopropanol to obtain a solvent-substituted gel;

[0037] 3) Use a mixture of hexamethyldisiloxane (HMDSO) / isopropanol with a volume ratio of 0.8:20 to modify the surface of the gel after solvent replacement in step 2) to obtain a surface-modified gel ;

[0038] 4), Step 3) The gel after surface modification is subjected to 40~60 o C dried under normal pressure for 1 day to obtain a complete high-surface mesoporous methylsilsesquioxane airgel block.

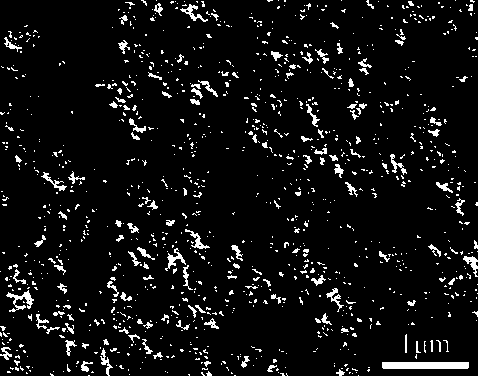

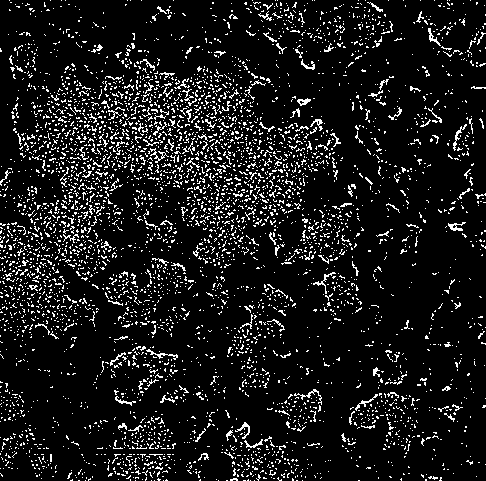

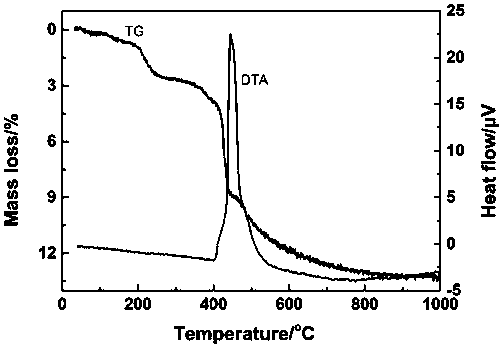

[0039] figure 1 For the scanning electron micrograph of the MSQ ...

Embodiment 2

[0049] 1) Add 0.2g of cetyltrimethylammonium chloride to 4 mL with a concentration of 4*10 -4 mol•L -1 Stir to dissolve in the hydrochloric acid solution, then add 2 mL of precursor methyltrimethoxysilane (MTMS), stir magnetically for 30 min under sealed conditions, then add 0.5 mL of 1,2-propylene oxide (PO), stir 1~2 min, put in 45 o Aging in C oven for 2 to 3 days;

[0050] 2) For the gel formed in step 1), use isopropanol for secondary solvent replacement to obtain the gel after solvent replacement. The solvent replacement process is to pour out the original solvent, pour isopropanol, and put it back after sealing. In the oven, the interval between each solvent replacement is 12~24h;

[0051] 3) Use a mixture of hexamethyldisiloxane (HMDSO) / isopropanol with a volume ratio of 0.8:20 to modify the surface of the gel after solvent replacement in step 2) to obtain a surface-modified gel ;

[0052] 4), Step 3) The gel after surface modification is subjected to 40~60 o C d...

Embodiment 3

[0054] 1) Add 0.3g of cetyltrimethylammonium chloride to 8 mL with a concentration of 6*10 -4 mol•L -1 Stir to dissolve in the hydrochloric acid solution, then add 5 mL of precursor methyltrimethoxysilane (MTMS), stir magnetically for 60 min under sealed conditions, then add 1.5 mL of 1,2-propylene oxide (PO), stir for 1 ~2 min, put in 50 o Aging in C oven for 2 to 3 days;

[0055] 2) For the gel formed in step 1), use isopropanol to perform solvent replacement four times to obtain the gel after solvent replacement. The solvent replacement process is to pour out the original solvent, pour isopropanol, and put it back after sealing. In the oven, the interval between each solvent replacement is 12~24h;

[0056] 3) Use a mixture of hexamethyldisiloxane (HMDSO) / isopropanol with a volume ratio of 0.8:20 to modify the surface of the gel after solvent replacement in step 2) to obtain a surface-modified gel ;

[0057] 4), Step 3) The gel after surface modification is subjected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com