Preparation method of celecoxib impurity B

A technology for celecoxib and impurities, which is applied in the field of preparation of impurities B in the celecoxib process, and can solve the problems of increasing production costs, being unsuitable for practical production applications, and having low yields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Synthesis of 4,4,4-trifluoro-1-(4-methylphenyl)butane-1,3-dione

[0034] Under nitrogen protection, methyl tert-butyl ether (3.0 L) and 20% by weight sodium ethoxide ethanol solution (3.55 kg, 10.43 mol) were added respectively, and the nitrogen was replaced three times. Control the temperature not to exceed 25±5°C, stir mechanically, and add ethyl trifluoroacetate (3) (1.27kg, 8.94mol) and p-methylacetophenone (4) (1.0kg, 7.45mol) in batches in sequence. Under nitrogen protection, the reaction temperature was controlled at 25±5° C., and mechanically stirred for 24 hours. It was detected by TLC that the raw materials disappeared and the reaction was completed (developing solvent: petroleum ether / ethyl acetate, volume ratio: 1 / 1).

[0035] Stop the reaction, add 5% by weight hydrochloric acid solution (6.5L) to the reaction solution to adjust the pH to 7.0-8.0, let stand for 15min, separate layers, collect the organic phase, extract the aqueous phase with eth...

Embodiment 2

[0036] Embodiment 2: Preparation of celecoxib impurity B

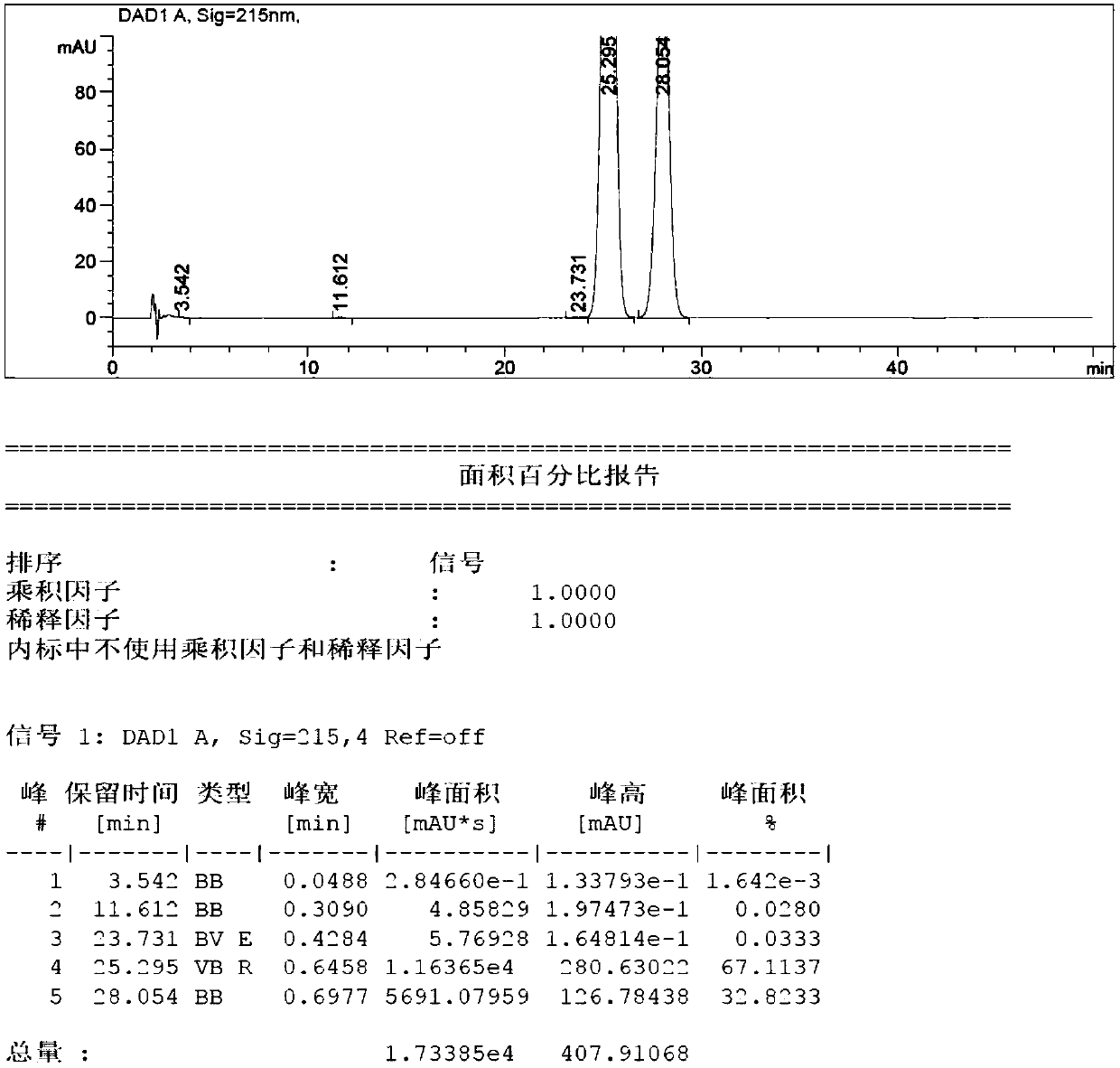

[0037] Add absolute ethanol (19.2L), purified water (4.8L) and 4,4,4-trifluoro-1-(4-methylphenyl)butane-1,3-dione (1.6 kg, 6.84mol), dissolved completely, added 4-hydrazinobenzenesulfonamide hydrochloride (1.61kg, 7.18mol), stirred mechanically, raised the temperature to reflux, reacted for 20h, compound 1 disappeared as detected by HPLC, and stopped heating. The reaction mixture was cooled and crystallized. When the temperature reached 20°C, the temperature was kept and stirred for 3h. Centrifuge, wash the filter cake with a small amount of mixed solvent (absolute ethanol / water: 1 / 1), collect the solid wet product, and dry the wet product at 45°C for 16 hours to obtain the crude product. The content of impurity B in the crude product is 32.8% as detected by HPLC (attached figure 1 ).

Embodiment 3

[0038] Embodiment 3: Preparation of celecoxib impurity B

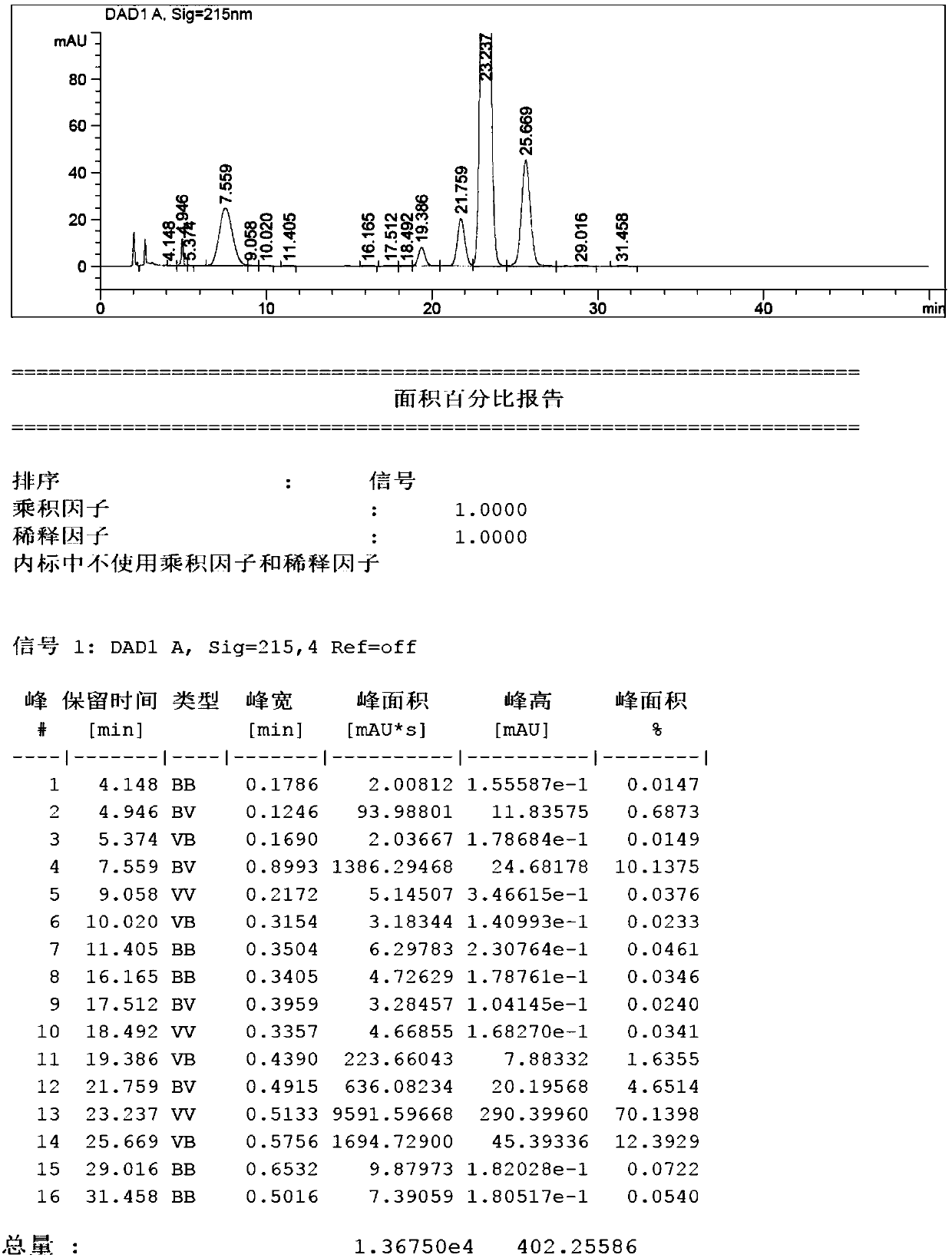

[0039]Take 10g of 4,4,4-trifluoro-1-(4-methylphenyl)butane-1,3-dione, add ethanol (120mL) to dissolve completely, measure its pH value to 7~8, then add Purified water (30mL) and 4-hydrazinobenzenesulfonamide hydrochloride (10.2g, 46.0mmol) were stirred, heated up, and refluxed for 20h. After sampling, HPLC detected that the content of impurity B reached 26.1%. The reaction was stopped, and concentrated to dryness under reduced pressure. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com