Manufacturing method for water absorbing material

A technology of water-absorbing material and manufacturing method, which is applied in the directions of paper coating, special paper, tissue paper/absorbent paper, etc., can solve the problems of leakage of polymer water-absorbing resin, insufficient contact of wood pulp fiber, hidden danger of water-absorbing material, etc. Conductivity, good gel water retention, enhanced interweaving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

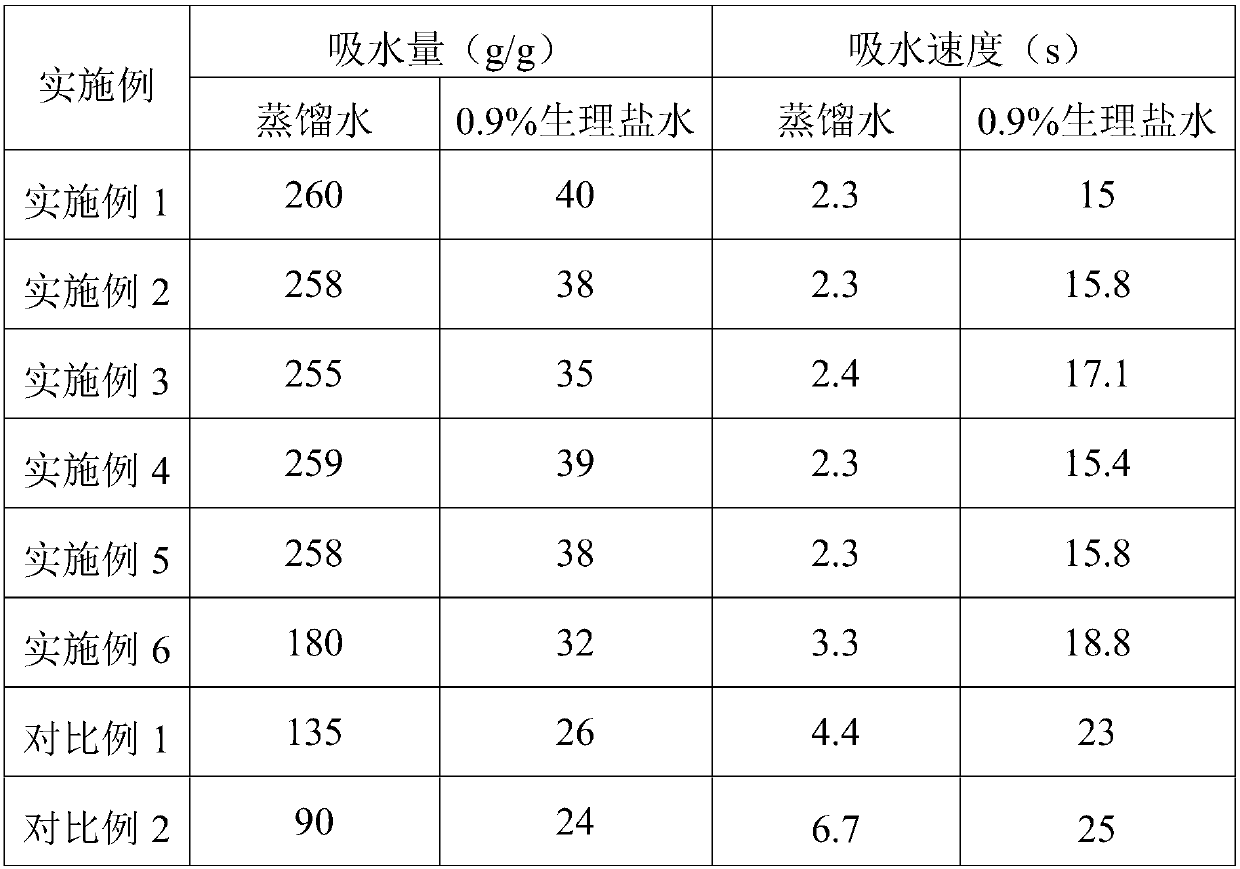

Examples

Embodiment 1

[0052] Put softwood pulp and hardwood pulp in a hydraulic pulper for pulping. The concentration of the pulp is 5wt%, and the pulping time is 15min. Then the pulped pulp is placed in a disc mill for grinding Pulp to split the fibers in softwood pulp and hardwood pulp, the refining power during the refining process is 300kW, the throughput of the slurry during the refining process is 2000L / min, and the refining concentration is 4.0wt%; The ground slurry is transported to the mixing tank for mixing, the weight ratio of softwood pulp to hardwood pulp is 30:70, and the polyamide polyepichlorohydrin resin wet strength agent is added during the mixing process And hydrophilic silicone softener to obtain the surface slurry and the bottom slurry; then, the surface slurry and the bottom slurry are conveyed to the Internet through the headbox, and the on-line concentration of the surface slurry and the bottom slurry is 0.7wt%, The surface slurry and the bottom slurry dehydrated by the wire...

Embodiment 2

[0058] Embodiment 2 is carried out in basically the same way as embodiment 1, except that:

[0059] The weight ratio of softwood pulp to hardwood pulp is 20:80.

Embodiment 3

[0061] Example 3 was carried out in the same manner as Example 1, except that:

[0062] The weight ratio of softwood pulp to hardwood pulp is 40:60.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com