Light-absorption material and application thereof in preparation of 3D printing solar cell panel

A solar panel and 3D printing technology, applied in the field of solar power generation, can solve the problems of small sunlight irradiation area, low photoelectric conversion efficiency, low power generation efficiency, etc., and achieve the effects of reliable insulation performance, high timeliness, and improved absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

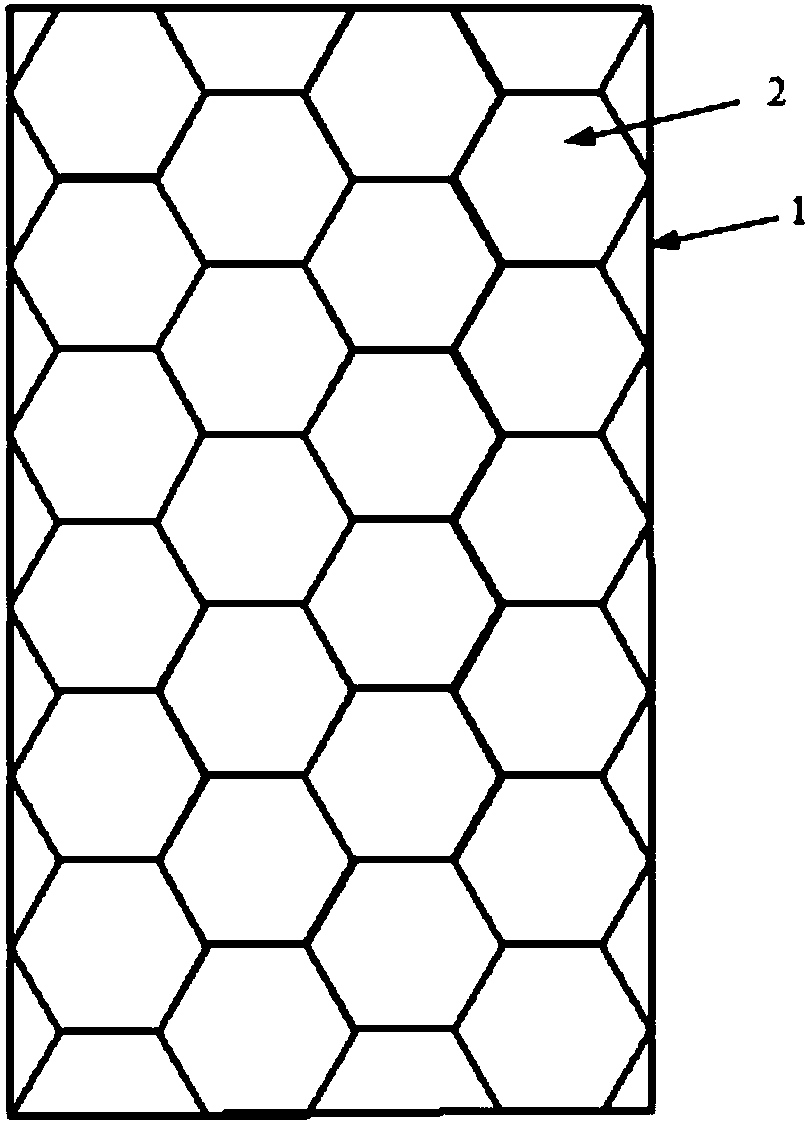

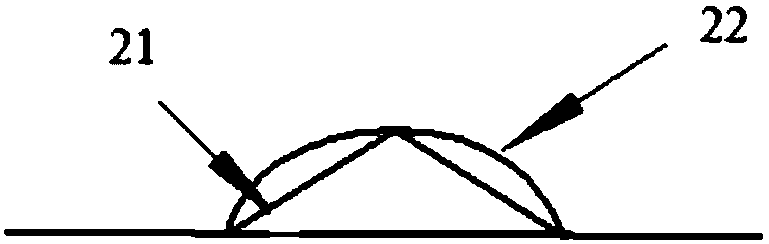

[0023] Such as Figure 1-2 As shown, a high-efficiency butterfly solar panel using 3D printing includes a substrate 1 and a plurality of light absorbers 2, each light absorber 2 is distributed on the same surface of the substrate 1 and arranged closely; the bottom of each light absorber 2 It is polygonal, and each polygon is provided with an inclined surface 21 that forms an arc with the horizontal plane; an elliptical protruding part 22 is provided on the inclined surface.

[0024] The polygon is a regular pentagon.

[0025] The side length of the polygon is 1 cm.

[0026] The arc is 15°.

Embodiment 2

[0028] Such as Figure 1-2 As shown, a high-efficiency butterfly solar panel using 3D printing includes a substrate 1 and a plurality of light absorbers 2, each light absorber 2 is distributed on the same surface of the substrate 1 and arranged closely; the bottom of each light absorber 2 It is polygonal, and each polygon is provided with an inclined surface 21 that forms an arc with the horizontal plane; an elliptical protruding part 22 is provided on the inclined surface.

[0029] The polygon is a regular hexagon.

[0030] The side length of the polygon is 5 cm.

[0031] The arc is 26°.

Embodiment 3

[0033] Such as Figure 1-2 As shown, a high-efficiency butterfly solar panel using 3D printing includes a substrate 1 and a plurality of light absorbers 2, each light absorber 2 is distributed on the same surface of the substrate 1 and arranged closely; the bottom of each light absorber 2 It is polygonal, and each polygon is provided with an inclined surface 21 that forms an arc with the horizontal plane; an elliptical protruding part 22 is provided on the inclined surface.

[0034] The polygon is a regular hexagon.

[0035] The side length of the polygon is 6 cm.

[0036] The arc is 40°.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap