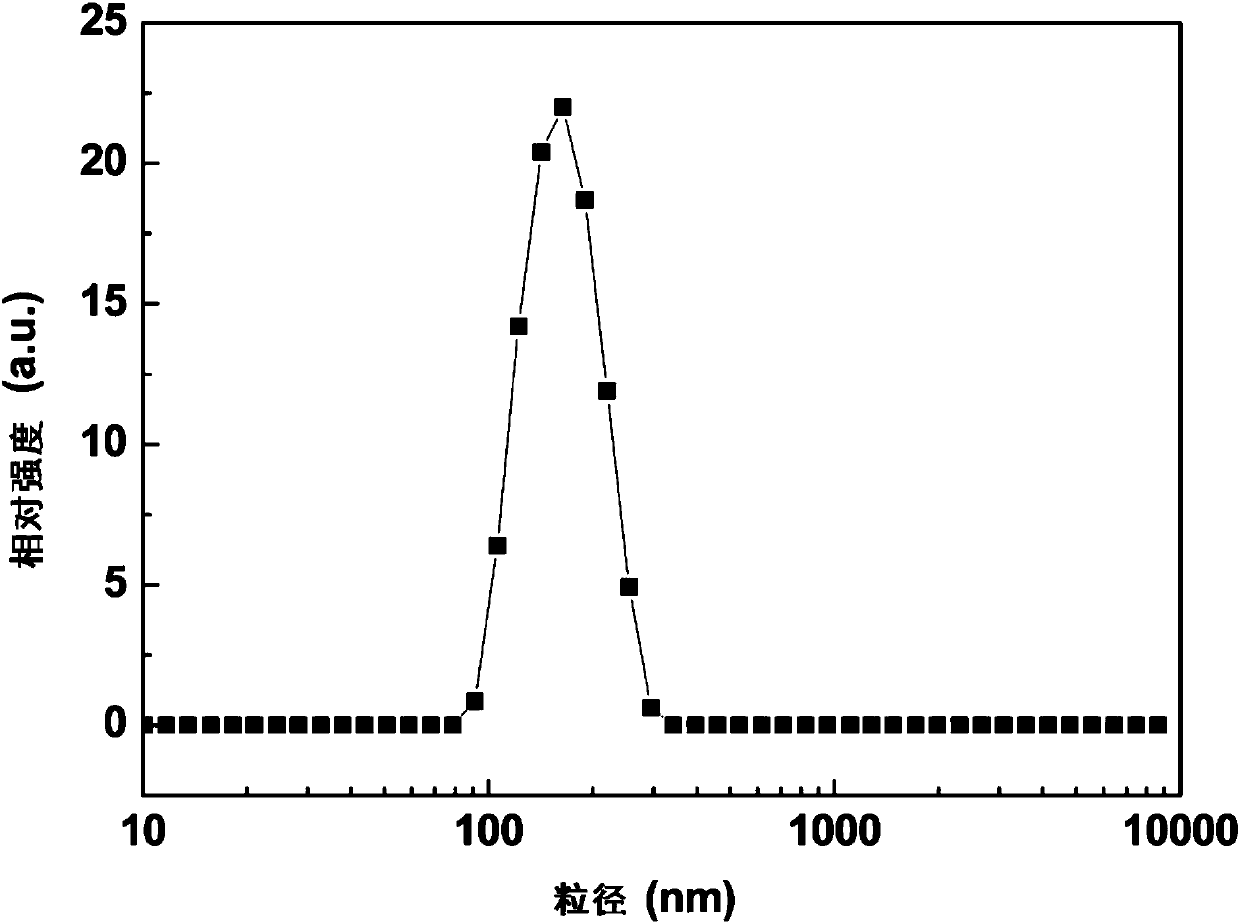

Lignosulfonate-silicon dioxide mesoporous nanosphere and preparation method thereof

A technology of lignosulfonate and silica, which is applied in the fields of botanical equipment and methods, nanotechnology, nanotechnology, etc., can solve problems such as unreported research, achieve simple preparation process, improve use efficiency, and easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

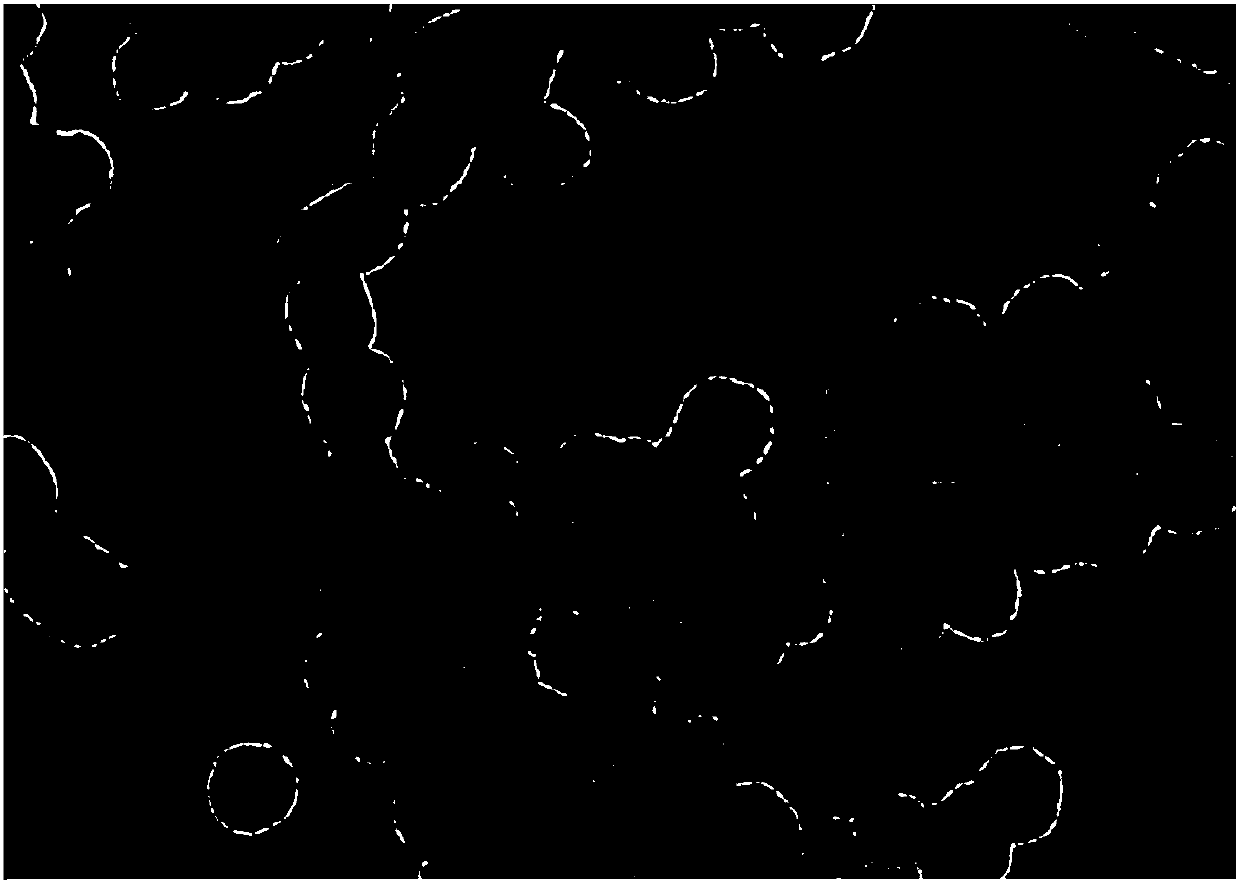

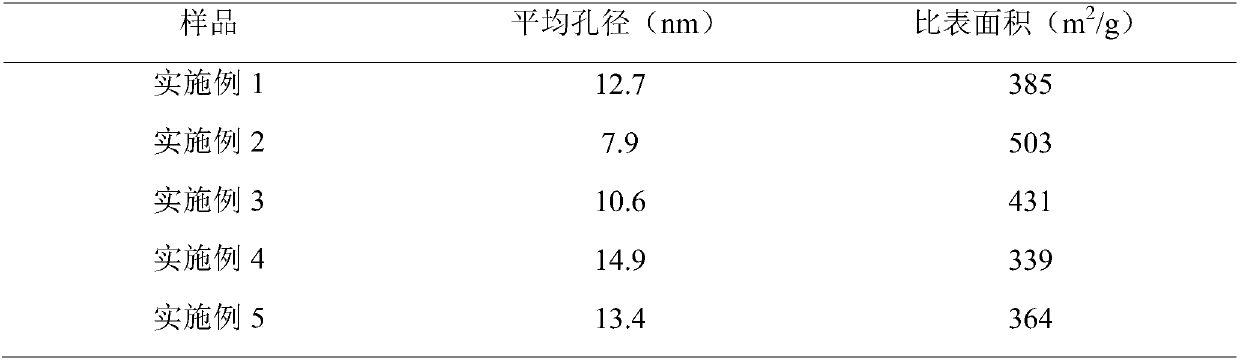

Examples

Embodiment 1

[0026] The preparation method of lignosulfonate-silicon dioxide mesoporous nanospheres of this embodiment comprises the following steps:

[0027] 1) get 120g sodium lignosulfonate (NaLS), be dissolved in water, be mixed with the NaLS aqueous solution that mass percent is 60%;

[0028] 2) Take ethanol, and prepare ethanol / water mixture according to the mass ratio of ethanol and water of 2:1; take cetyltrimethylammonium bromide (CTAB), dissolve it in ethanol / water mixture to prepare 50% CTAB solution;

[0029] 3) Mix the NaLS aqueous solution in step 1) with the CTAB solution in step 2) according to a mass ratio of 2.35:1, stir at room temperature for 10 minutes at a stirring speed of 700 r / min, and then let stand for 1 hour to obtain NaLS / CTAB composite system;

[0030] 4) Take 0.1g of the NaLS / CTAB composite system in step 3), dissolve it in 20g of ethanol, and prepare a mass concentration of 5.0mg.g -1The ethanol solution of the NaLS / CTAB complex, take 6g of the ethanol so...

Embodiment 2

[0033] The preparation method of lignosulfonate-silicon dioxide mesoporous nanospheres of this embodiment comprises the following steps:

[0034] 1) get 120g potassium lignosulfonate (KLS), be dissolved in water, be mixed with the KLS aqueous solution that mass percent is 70%;

[0035] 2) Take isopropanol, and prepare isopropanol / water mixture according to the mass ratio of isopropanol to water at 3:1; take dodecyltrimethylammonium chloride (DTAC), dissolve it in isopropanol It is 50% DTAC solution that the mass percent is prepared in the water / water mixture;

[0036] 3) Mix the KLS aqueous solution in step 1) with the DTAC solution in step 2) according to the mass ratio of 2.82:1, stir at room temperature for 8 minutes, the stirring speed is 800r / min, and then stand still for 0.5h to obtain KLS / DTAC composite system;

[0037] 4) Take 0.06g of the KLS / DTAC composite system in step 3), dissolve it in 20g of isopropanol, and prepare a mass concentration of 3.0mg.g -1 The isop...

Embodiment 3

[0040] The preparation method of lignosulfonate-silicon dioxide mesoporous nanospheres of this embodiment comprises the following steps:

[0041] 1) get 120g sodium lignosulfonate (NaLS), be dissolved in water, be mixed with the NaLS aqueous solution that mass percent is 50%;

[0042] 2) Take isopropanol, and prepare isopropanol / water mixture according to the mass ratio of isopropanol and water at 1:1; take cetyltrimethylammonium bromide (CTAB), dissolve it in isopropanol It is 40% CTAB solution that mass percentage is prepared into in the water / water mixture;

[0043] 3) Mix the NaLS aqueous solution in step 1) with the CTAB solution in step 2) according to a mass ratio of 1.88:1, stir at room temperature for 15 min at a stirring speed of 750 r / min, and then let stand for 0.5 h to obtain NaLS / CTAB composite system;

[0044] 4) Take 0.12g of the NaLS / CTAB composite system in step 3), dissolve it in 20g of isopropanol, and prepare a mass concentration of 6.0mg.g -1 The isopr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap