Novel poly-sulfide rubber waterproof material and preparation method thereof

A technology of polysulfide rubber and waterproof material, applied in the field of polysulfide rubber material, can solve the problems of toxic waste water discharge, large pollution discharge, environmental pollution, etc., and achieves increased impact strength, low water vapor transmission rate, and no environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

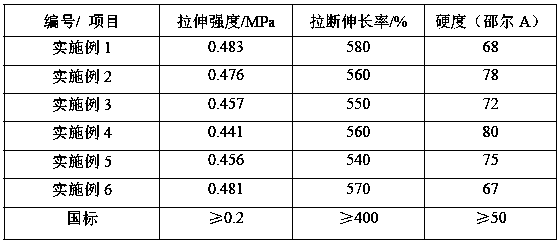

Examples

Embodiment 1

[0025] A polysulfide rubber waterproof material is prepared from the following raw materials in parts by weight.

[0026] 180 parts of polyethylene adipate (relative molecular mass: 1100), 145 parts of aromatic diisocyanate, 90 parts of 2-mercaptoethanol, 8 parts of zinc oxide, 2 parts of regulator phosphoric acid and 2 parts of oxalic acid, acidic catalyst toluene 1 part of acid amine, 9 parts of plasticizer phthalate, 9 parts of epoxy resin reactive diluent, 4 parts of crosslinking agent, 4 parts of reinforcing agent carbon black.

[0027] The preparation steps are as follows:

[0028] (1) Synthesis of prepolymer: Weigh polyethylene adipate and regulator according to parts by weight, put them into a mixer and stir evenly, the stirring speed is 35r / min, and the stirring time is 5min, and stir evenly Put the mixed material into the cylinder stirring vacuum dryer, vacuum dehydrate under the conditions of 110°C~130°C, 0.083~0.087Mpa, until the water content is ≥0.05%; cool down...

Embodiment 2

[0032] A polysulfide rubber waterproof material is prepared from the following raw materials in parts by weight.

[0033] 185 parts of polyethylene adipate (relative molecular mass: 1300), 138 parts of aromatic diisocyanate, 85 parts of 2-mercaptopropanol, 9 parts of zinc oxide, 2 parts of regulator oxalic acid and 2 parts of acetic acid, acidic catalyst 1 part of ammonium toluamide, 4 parts of plasticizer phthalate and 5 parts of chlorinated paraffin, 7 parts of epoxy resin reactive diluent, 4 parts of crosslinking agent, 4 parts of reinforcing agent carbon black.

[0034] The preparation method is the same as that in Example 1.

Embodiment 3

[0036] A polysulfide rubber waterproof material is prepared from the following raw materials in parts by weight.

[0037] 190 parts of polyethylene adipate (relative molecular mass: 1500), 131 parts of aromatic diisocyanate, 80 parts of 3-mercaptopropanol, 10 parts of zinc oxide, 2 parts of regulator phosphoric acid and 2 parts of acetic acid, acidic catalyst 1 part of ammonium toluamide, 4 parts of plasticizer phthalate and 5 parts of phosphate ester, 8 parts of epoxy resin reactive diluent, 4 parts of crosslinking agent, 4 parts of reinforcing agent carbon black.

[0038] The preparation method is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com