Equipment outlet casing adapting electrical conductivity adaptive control composite

An adaptive regulation and composite material technology, applied in the direction of heterogeneous insulating materials, circuits, electrical components, etc., can solve problems such as large size, internal heating, quality problems, etc., achieve efficiency and economic benefits, improve heat dissipation performance, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

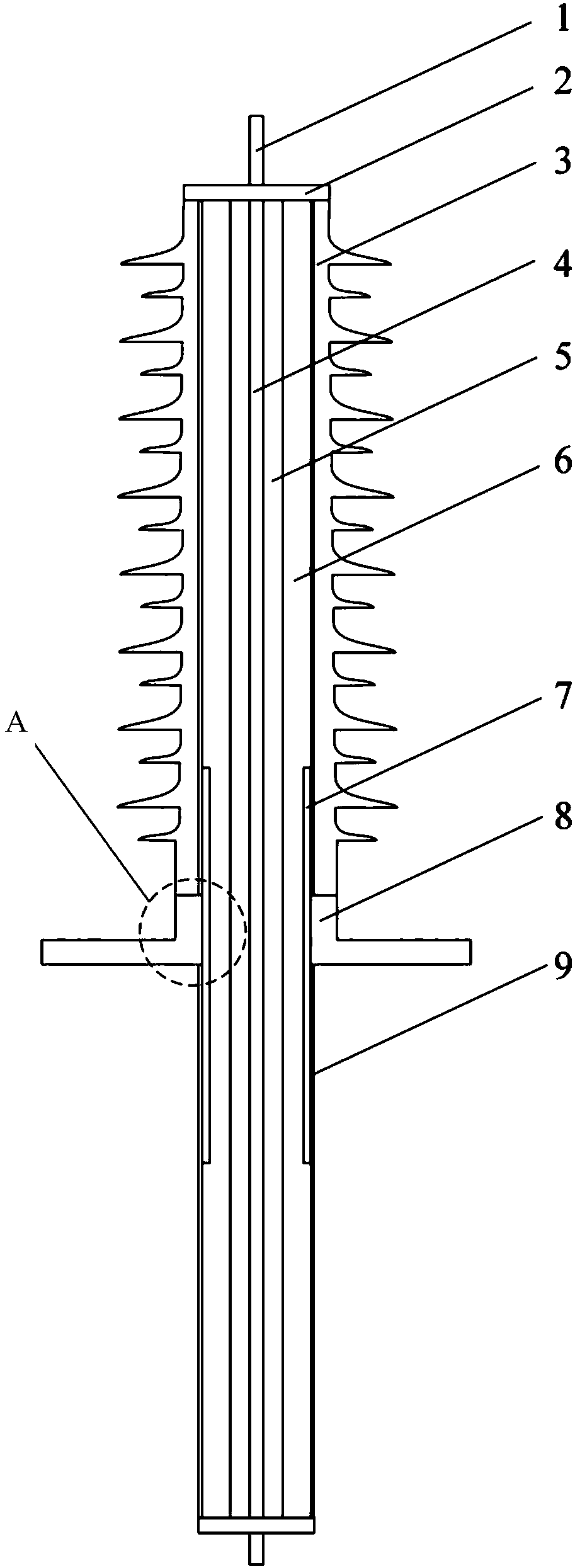

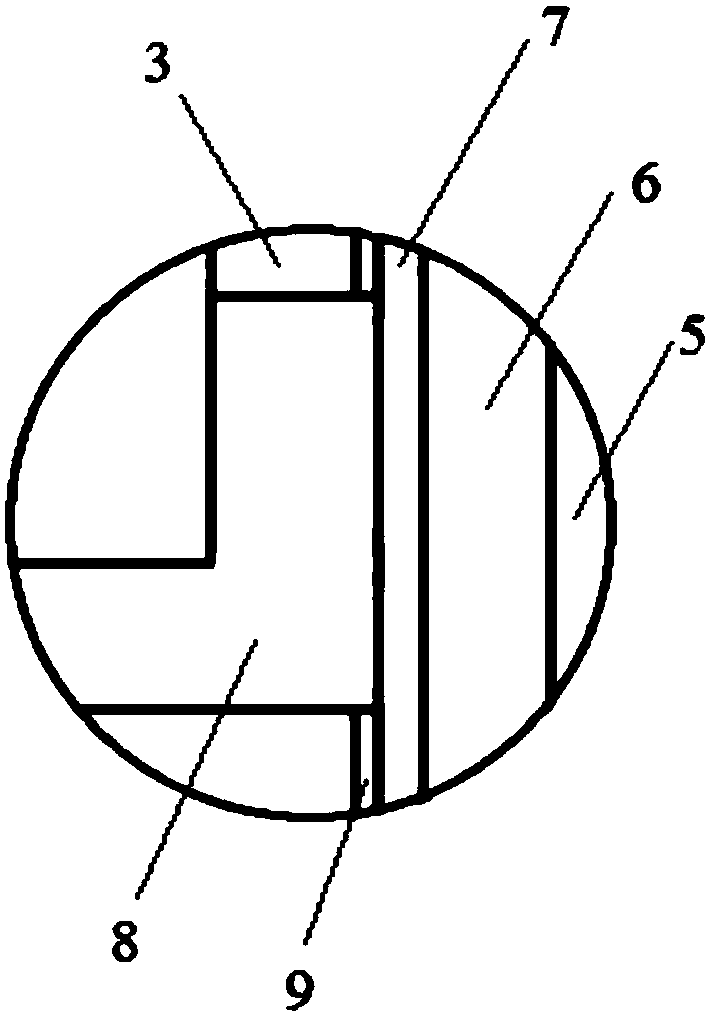

[0031] The equipment outlet bushing of this embodiment is used under the DC voltage level of 110kV. The inorganic filler powder particles in the equalizing layer 5 and the electrode extension layer 7 are all made of ZnO pressure-sensitive ceramic powder, and the organic material with high dielectric strength is made of 100 parts of three Yuan ethylene propylene rubber; wherein, the particle size of the ZnO pressure-sensitive ceramic powder used in the equalizing layer 5 is 30-50 μm, and the number of parts of the ZnO pressure-sensitive ceramic powder is 80 parts; the electrode extension layer 7 is The particle size of the ZnO pressure-sensitive ceramic powder used is 150-200 μm, and the number of parts of the ZnO pressure-sensitive ceramic powder is 200 parts.

[0032] In this embodiment, the threshold field strength of the conductivity self-adaptive regulation composite material is adjusted by multi-element blending and doping by introducing 20 parts of carbon black into both th...

Embodiment 2

[0034] The equipment outlet bushing of this embodiment is used at a DC voltage level of 500kV. The inorganic filler powder particles of the pressure equalization layer 5 and the electrode extension layer 7 are respectively SiC powder and ZnO varistor ceramic powder, and high dielectric strength organic materials are all made of 100 parts of epoxy resin; wherein, the particle size of the SiC powder used in the equalizing layer 5 is 300-500nm, and the number of parts of the SiC powder is 40 parts; the ZnO pressure-sensitive ceramic powder particles used in the electrode extension layer 7 The size is 150-200 μm, and the number of parts of the ZnO pressure-sensitive ceramic powder is 200 parts.

Embodiment 3

[0036] The equipment outlet bushing of this embodiment is used under the AC voltage level of 330kV. The inorganic filler powder particles in the equalizing layer 5 adopt ZnO pressure-sensitive ceramic powder and SiC powder, and the inorganic filler powder particles in the electrode extension layer 7 adopt ZnO pressure-sensitive ceramic powder. Sensitive ceramic powder and CB powder, high dielectric strength organic materials are all made of 100 parts polypropylene; among them,

[0037] The particle sizes of the ZnO varistor ceramic powder and SiC powder used in the equalizing layer 5 are 30-50 μm and 600-800 nm respectively, and the parts of ZnO varistor ceramic powder and SiC powder are 50 parts and 20 parts respectively ;

[0038] The particle sizes of the ZnO varistor ceramic powder and CB powder used in the electrode extension layer 7 are 100-125 μm and 30 nm respectively, and the parts of ZnO varistor ceramic powder and CB powder are 100 parts and 20 parts respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com