Method for synthesizing CsPbBr3 nanocrystal through centrifugal stirring

A technology of nano crystals and centrifuges, applied in the direction of nanotechnology, chemical instruments and methods, luminescent materials, etc., can solve the problems of hidden safety hazards for operators and users, and achieve the effects of convenient operation, industrial production, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A Centrifugal Stirring Synthesis of CsPbBr 3 The method for nanocrystals specifically comprises the following steps:

[0026] (1) CsBr and PbBr with a molar ratio of 1:1 2 (total weight 1 g) was dissolved in 2 ml of DMSO to obtain a mixed solution of 0.5 g / ml;

[0027] (2) Place the mixed solution obtained in step (1) in a high-speed centrifuge, centrifuge for 5 hours at a speed of 900rpm, and make the CsBr and PbBr in the mixed solution 2 Dissolve, let stand for 30 minutes after centrifugation, pour off the supernatant, then inject 0.5 ml of DMSO to wash once, and then introduce the washed solution into a conical funnel (covered with two layers of filter paper);

[0028] (3) The conical funnel in step (2) was placed in an oven, baked at 100°C, vacuumed at 1 MPa, baked for 10 h, and finally cooled to room temperature to obtain CsPbBr 3 Nanocrystalline powder.

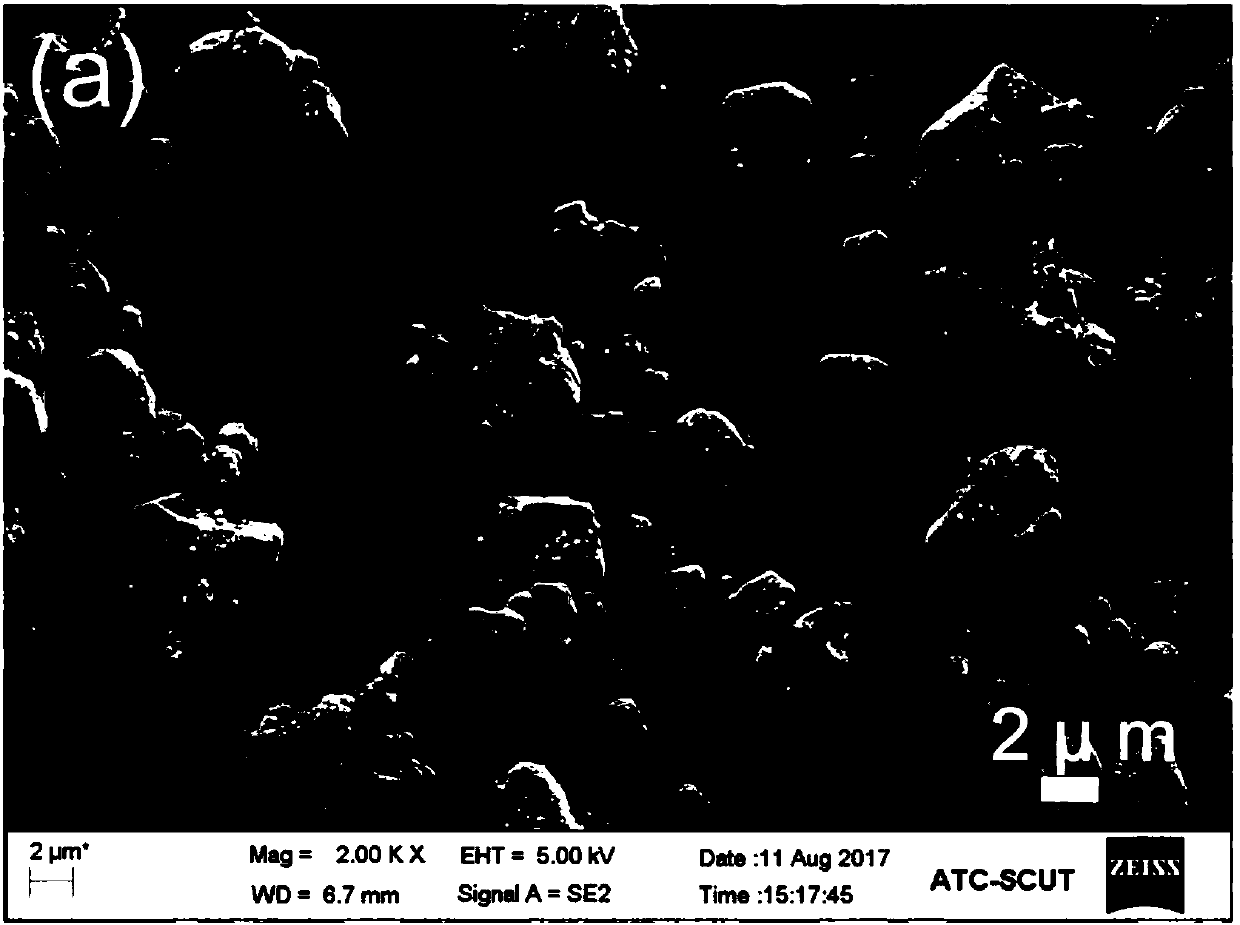

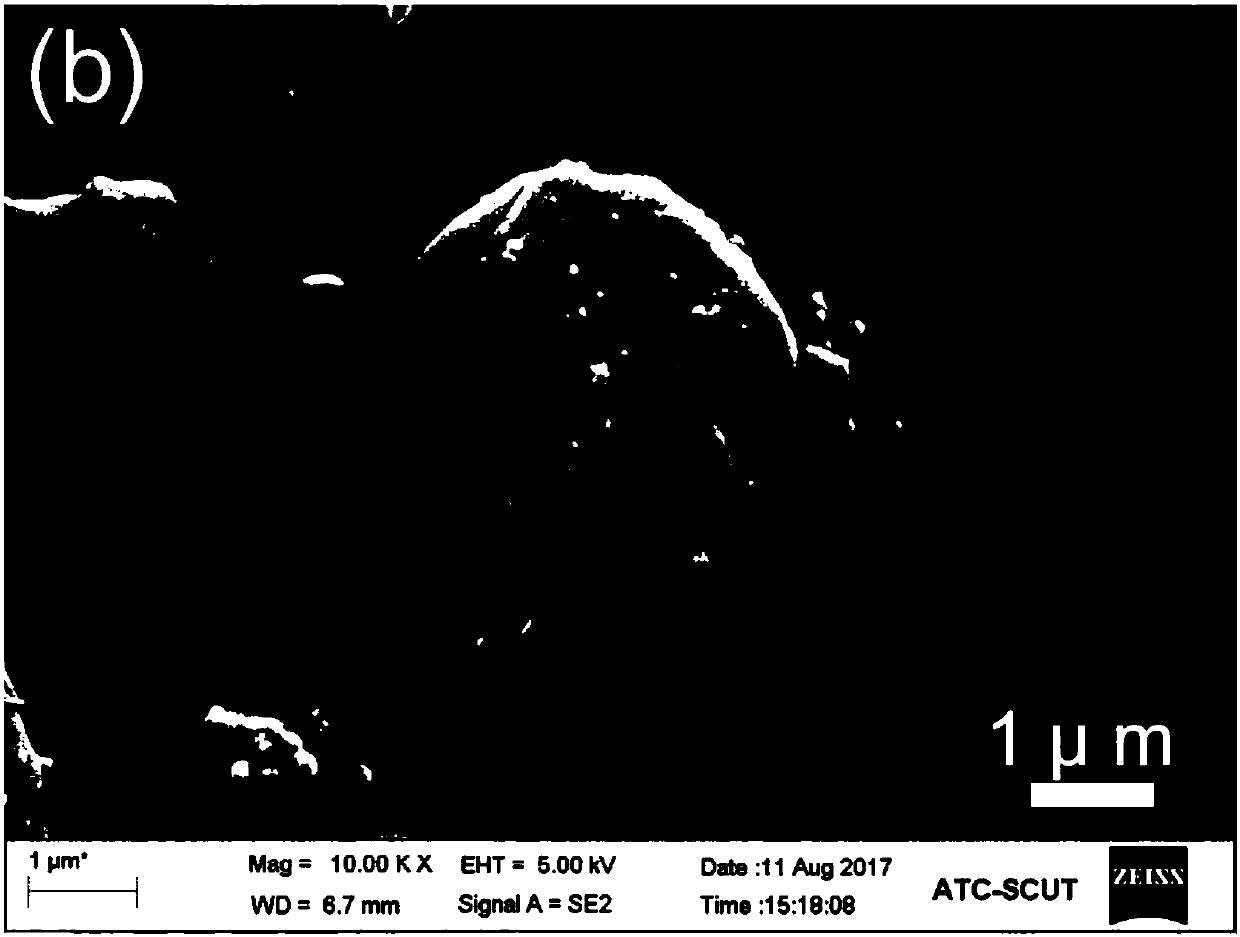

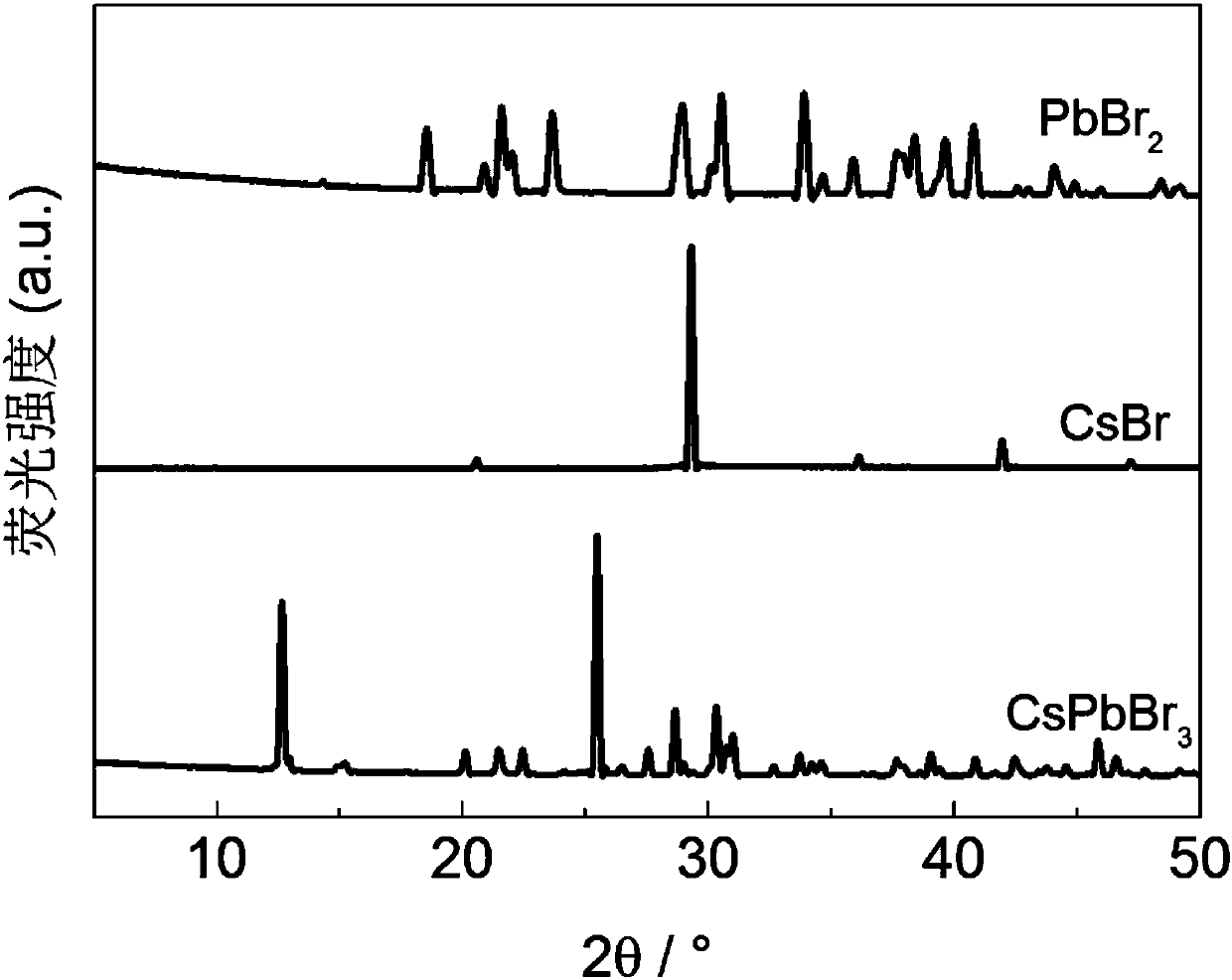

[0029] Synthetic-CsPbBr 3 Scanning electron microscope (SEM) images of nanocrystals at different magnific...

Embodiment 2

[0033] A Centrifugal Stirring Synthesis of CsPbBr 3 The method for nanocrystals specifically comprises the following steps:

[0034] (1) CsBr and PbBr with a molar ratio of 5:1 2 (total weight 2 g) was dissolved in 1 ml of DMSO to obtain a mixed solution of 2 g / ml;

[0035] (2) Place the mixed solution obtained in step (1) in a high-speed centrifuge and centrifuge for 3 hours at a speed of 2000 rpm to make the CsBr and PbBr in the mixed solution 2 Dissolve, let stand for 50 minutes after centrifugation, pour off the supernatant, then inject 1 ml of DMSO to wash 3 times, and then introduce the washed solution into a conical funnel (covered with two layers of filter paper);

[0036] (3) Put the conical funnel in step (2) into the oven, bake at 120°C, vacuum at 0.5MPa, bake for 5 hours, and finally cool to room temperature to obtain CsPbBr 3 Nanocrystalline powder.

[0037] The synthesized CsPbBr 3 Nanocrystals were mixed with PDMS to obtain a film with a diameter of 3 mm an...

Embodiment 3

[0039] A Centrifugal Stirring Synthesis of CsPbBr 3 The method for nanocrystals specifically comprises the following steps:

[0040] (1) CsBr and PbBr with a molar ratio of 10:1 2 (total weight 3 g) was dissolved in 1 ml of DMSO to obtain a mixed solution of 3 g / ml;

[0041] (2) Place the mixed solution obtained in step (1) in a high-speed centrifuge and centrifuge for 5 hours at a speed of 1000 rpm to make the CsBr and PbBr in the mixed solution 2 Dissolve, let stand for 60 minutes after centrifugation, pour off the supernatant, then inject 0.5 ml of DMSO to wash 5 times, and then introduce the washed solution into a conical funnel (spread with two layers of filter paper);

[0042](3) Put the conical funnel in step (2) into the oven, bake at 150°C, vacuum at 1 MPa, bake for 2 hours, and finally cool to room temperature to obtain CsPbBr 3 Nanocrystalline powder.

[0043] The synthesized CsPbBr 3 Nanocrystals were mixed with PDMS to obtain a film with a diameter of 3mm and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com