Chemical phosphorus removal automatic control device and control method implemented by same

An automatic control device, chemical phosphorus removal technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of cost increase, difficulty in phosphorus removal, large floor area, etc., and is not easy to deform Effects of clogging, accelerated separation speed, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

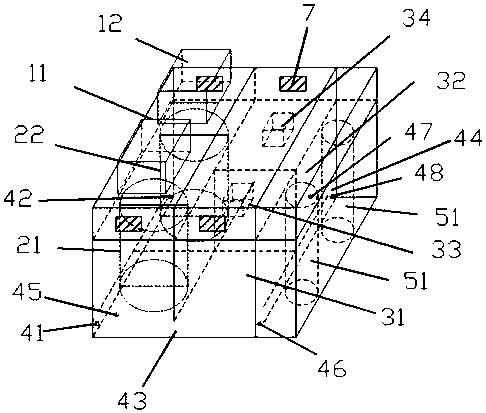

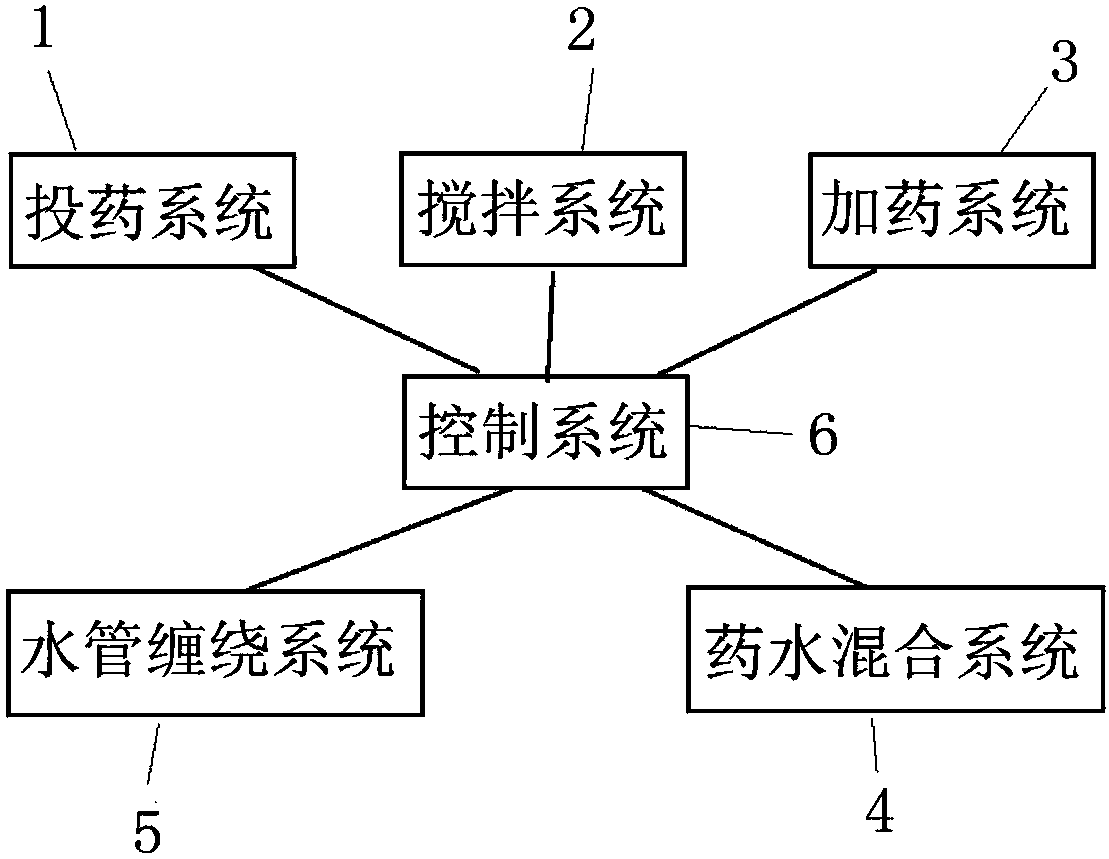

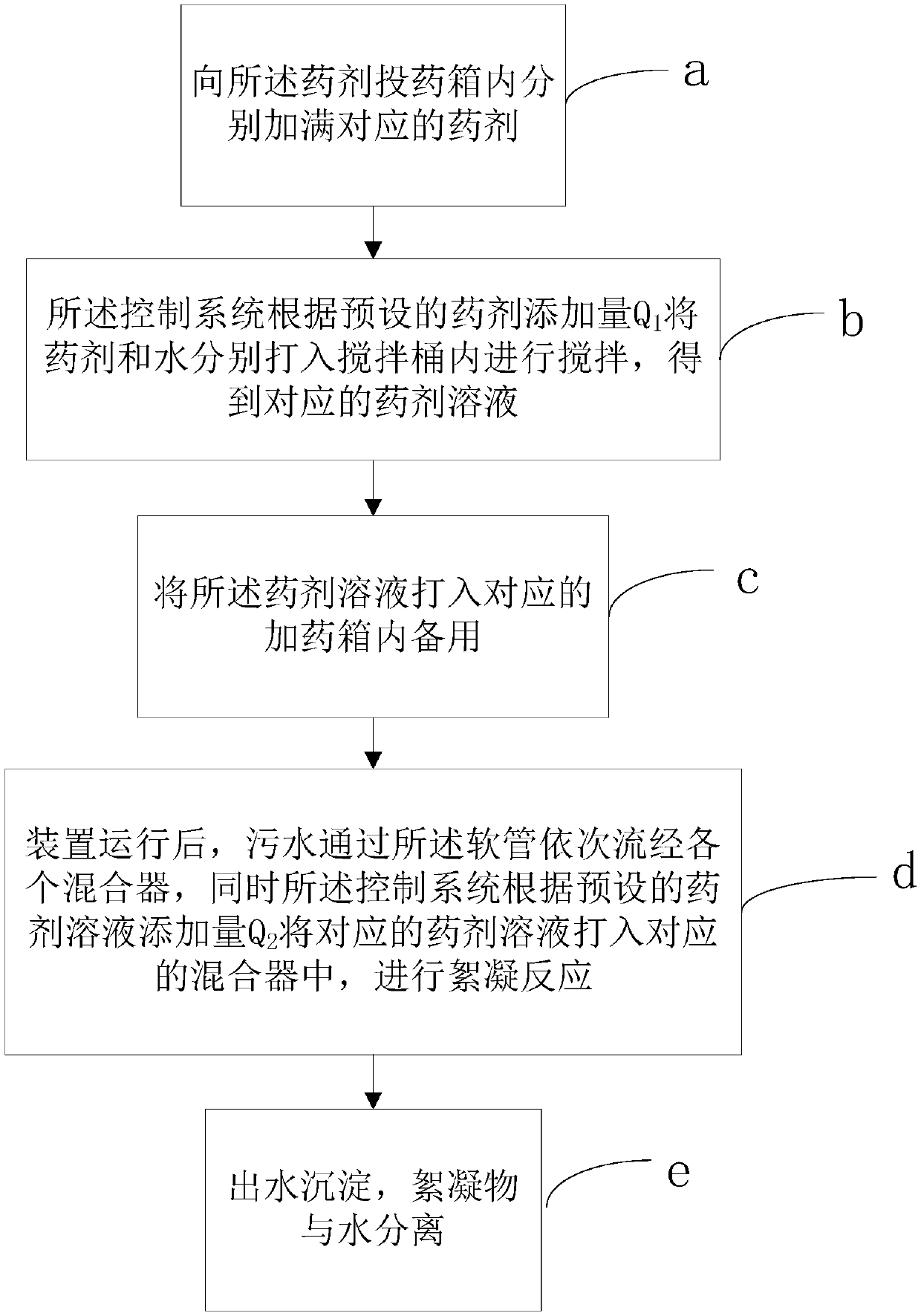

[0029] see Figure 1 to Figure 4 As shown, it is the control diagram of the automatic control device for chemical phosphorus removal of the present invention, the structural diagram of the automatic control device for chemical phosphorus removal in Embodiment 1, the flow chart of the control method of the automatic control device for chemical phosphorus removal, and the chemical phosphorus removal in Embodiment 1 Control flow chart of automatic control device.

[0030] combine figure 1 and figure 2 As shown, a chemical phosphorus removal automatic control device includes a box body and a dosing system 1, a stirring system 2, a dosing system 3, a medicine water mixing system 4, a water pipe winding system 5 and a control system 6 arranged in the box body The dosing system 1 includes several medicament dosing boxes, which are respectively used to place different medicaments, the medicament dosing box is provided with a medicament metering pump and a flow meter, and the medica...

Embodiment 2

[0042] A chemical phosphorus removal automatic control device as described above, the difference of this embodiment is that, as figure 2 As shown, the box body is provided with a heat dissipation vent 7, which is used to discharge the heat in the box body, and the number of heat dissipation vents 7 in this embodiment is four, which are respectively arranged in the box The two sides of the top help to dissipate the heat generated by the suction pump, stirring motor and dosing pump and other equipment during the operation of the device, so as to improve the safety of the device and reduce the failure rate.

Embodiment 3

[0044] The above-mentioned automatic control device for chemical phosphorus removal, the difference between this embodiment and the first embodiment lies in that the preset amount of medicament added to each mixing tank Q 1 are not the same, the dosage Q of the medicament 1 The calculation formula is:

[0045] Q 1 =a×b%

[0046] Among them, Q 1 is the added amount of the medicament, a is the added amount of water, b% is the concentration ratio of the medicament and water, and the range of b% is 1%-2% or 0.5‰-1‰.

[0047] The preset addition amount Q of medicament solution added in each said mixer 2 are not the same, the addition amount of the medicament solution Q 2 The calculation formula is:

[0048] Q 2 =c×d%

[0049] Among them, Q 2 is the added amount of the chemical solution, c is the added amount of sewage, d% is the concentration ratio of the chemical solution and sewage, and the range of d% is 3‰~1%.

[0050] As mentioned above, the sewage is stably added wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com