Acid liquid thickener and preparation method thereof

An acid thickener and initiator technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high frictional resistance, high temperature resistance and poor shear resistance, etc., to reduce frictional resistance, The effect of good high temperature resistance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

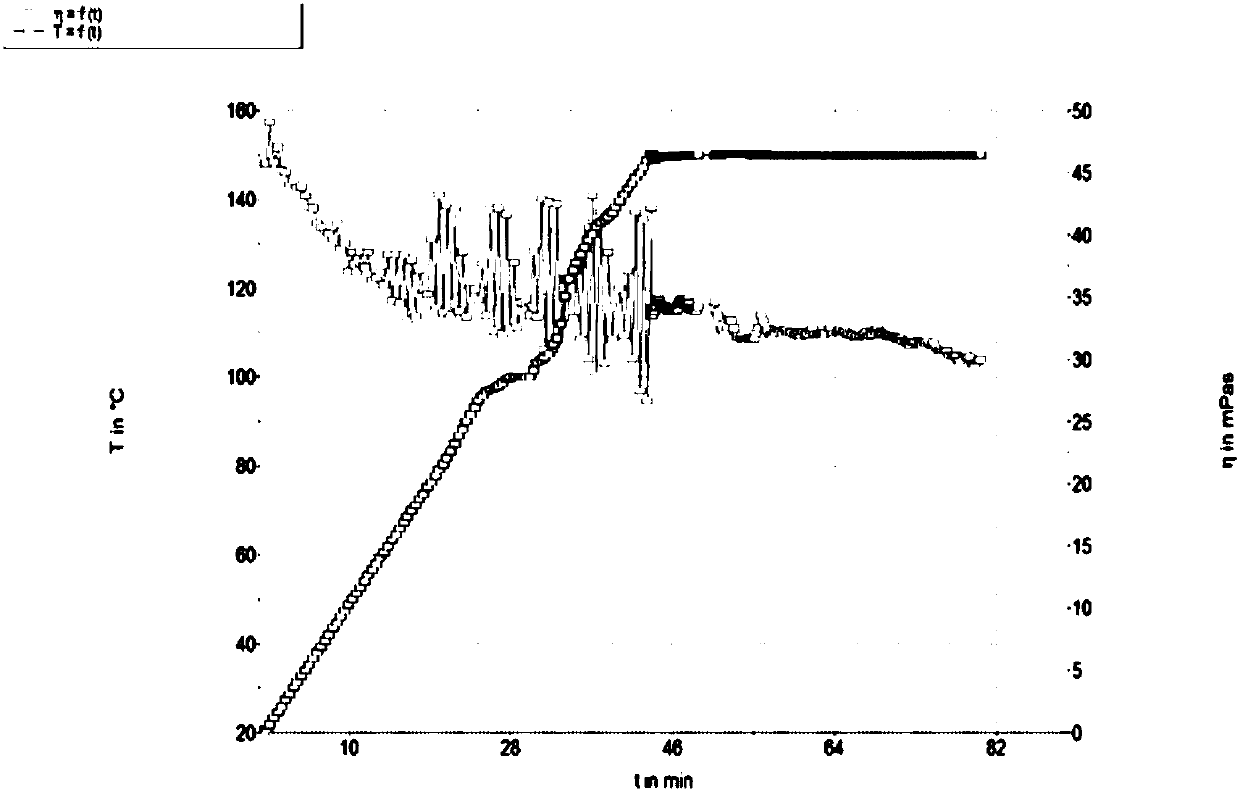

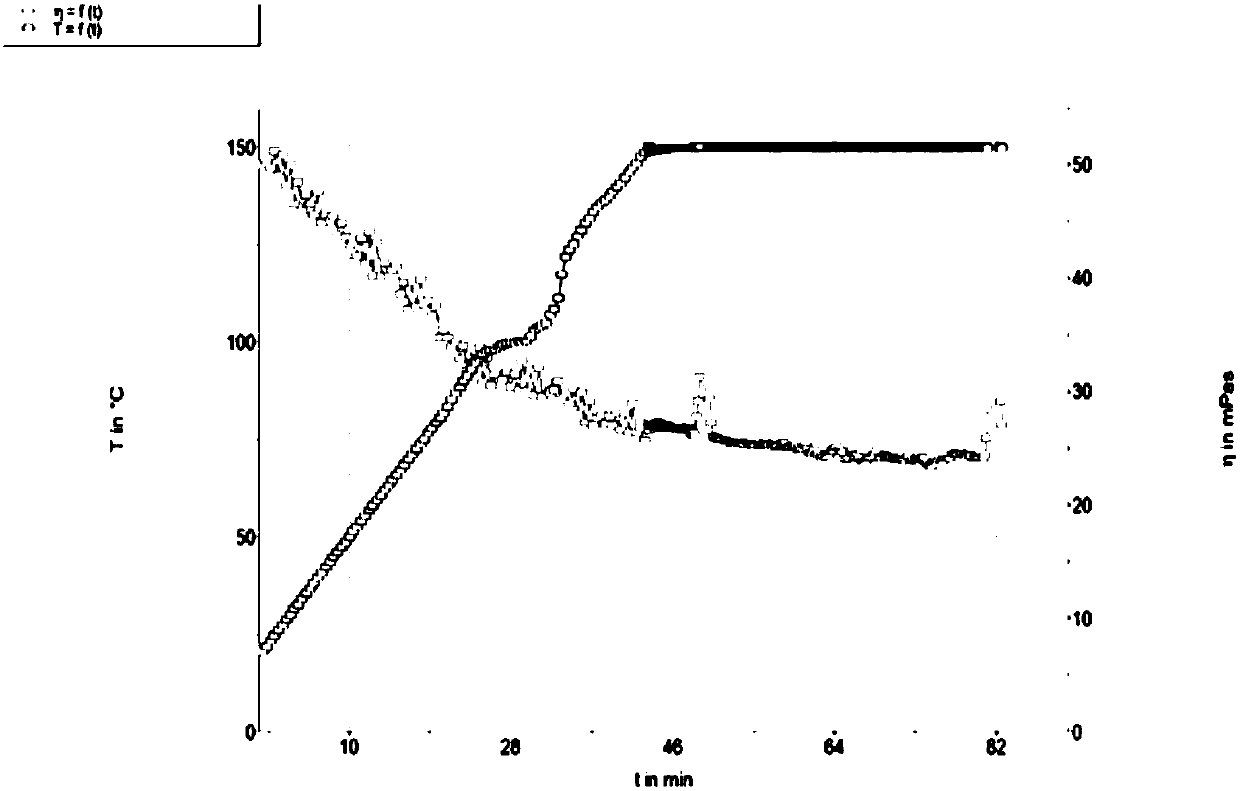

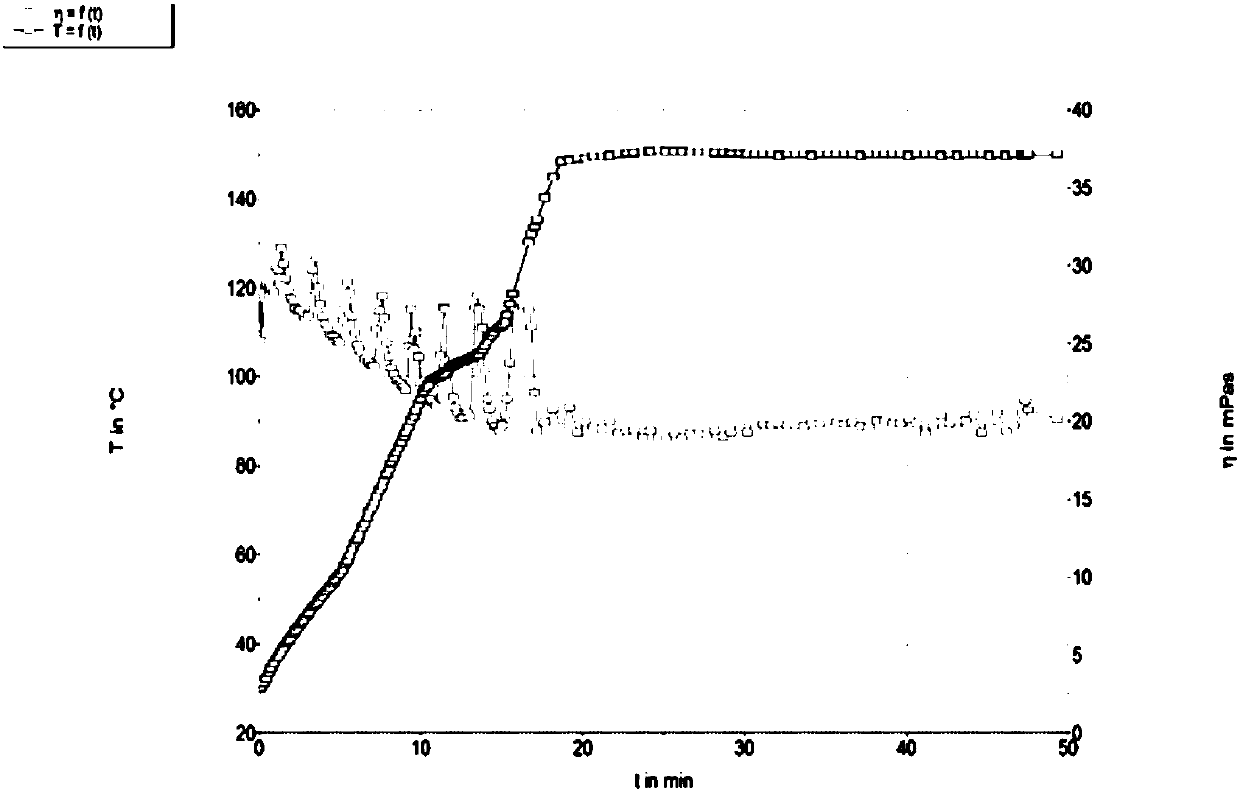

Image

Examples

preparation example Construction

[0035] In a second aspect, the embodiments of the present invention provide a method for preparing the above acid thickener, the method comprising the following steps:

[0036] Step 101, adding methacryloyloxyethyltrimethylammonium chloride, octadecyldimethylallylammonium chloride, and polyethylene glycol diacrylate into the reactor, and then adding deionized water, Prepare an aqueous solution with a mass concentration of 25%-40% of the total monomers, in which, methacryloyloxyethyltrimethylammonium chloride, octadecyldimethylallyl ammonium chloride, polyethylene glycol The mass ratio of alcohol diacrylate is 100:0.1-1:0.01-0.02.

[0037] Step 102, blow nitrogen into the reactor, then add an initiator, react at 20-30°C for 2-4h, then raise the temperature to 50-60°C, and continue the reaction to obtain a gel-like product.

[0038] Step 103, cutting the gel-like product into pieces, drying and pulverizing to obtain an acid thickener.

[0039] The preparation method of the aci...

Embodiment 1

[0058] This embodiment provides an acid thickener, by adding 140g of deionized water into a 500mL flask, and then adding 59.85g of methacryloyloxyethyltrimethylammonium chloride, after it is completely dissolved Add 0.15g octadecyldimethylallyl ammonium chloride, and then add 0.005g polyethylene glycol diacrylate after it dissolves completely, be mixed with the mass concentration of total monomer and be the aqueous solution of 30%, then in Nitrogen gas was passed into the flask, and 0.012 g of initiator potassium persulfate, 0.008 g of sodium bisulfite, and 0.01 g of azobisisobutylamidine hydrochloride were added, and nitrogen gas was continuously passed into the flask, and the flask was then placed in a thermostat at 20°C. React for 3 hours, then raise the temperature of the thermostat to 60°C, and continue the reaction for 3 hours to obtain a gel-like product, cut the gel-like product into pieces, dry it at 70°C, and then crush it into 80 meshes to obtain this example Acid t...

Embodiment 2

[0061] This embodiment provides an acid thickener, by adding 140g of deionized water into a flask with a volume of 500mL, and then adding 60g of methacryloyloxyethyltrimethylammonium chloride, and adding it after it is completely dissolved. 0.12g octadecyl dimethyl allyl ammonium chloride, after it is completely dissolved, add 0.006g polyethylene glycol diacrylate to prepare an aqueous solution with a mass concentration of 30.04% of the total monomer, and then add Nitrogen was passed into the flask, 0.014 g of initiator potassium persulfate, 0.012 g of sodium bisulfite, and 0.014 g of azobisisobutylamidine hydrochloride were added, and nitrogen gas was continued to be passed into the flask, and then reacted in a thermostat at 24°C. After 3 hours, the incubator was heated to 55°C, and the reaction was continued for 3 hours to obtain a gel-like product. The gel-like product was cut into pieces, dried at 78°C, and then crushed into 90 meshes to obtain the product provided in this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com