Production method and application of a discontinuous temperature-induced phase change gel fragrance-carrying filter stick

A production method and discontinuous technology are applied in the production field of discontinuous thermotropic phase-change gel fragrance-carrying filter rods, and can solve the problems of easy volatilization and loss of flavors and fragrances, less adsorption of fragrance substances, easy volatilization of fragrance substances, and the like. Achieve consistent taste and style, uniform release, and high aroma load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

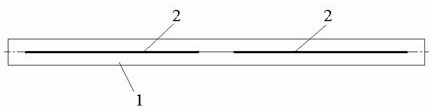

[0039] Example 1: Preparation of single discontinuous temperature-induced phase change gel fragrance-loaded filter stick with strawberry taste

[0040] Step (1), preparation of temperature-induced phase change fragrance-carrying composite colloid

[0041] Pour the fragrance-carrying substance prepared in proportion into water, and the fragrance-carrying substance consists of 7 kinds of polyethylene glycol, chitosan, sodium carboxymethylcellulose, starch, pectin, sodium alginate and β-cyclodextrin. Component composition, the ratio of each component is: 16:0.5:1:0.2:0.1:0.4:0.5. The weight ratio of fragrance carrier to water is 4:1, heat and stir at 55°C for 0.5h to fully melt and mix evenly to obtain a temperature-induced phase change composite colloid with a melting point of 45°C, then add strawberry essence, propylene glycol fat Ester and lycopene were added to the prepared composite colloid and stirred evenly. The weight of the added strawberry essence, propylene glycol fat...

Embodiment 2

[0045] Example 2: Preparation of discontinuous temperature-induced phase change gel fragrance-loaded filter stick with sweet orange taste

[0046] The preparation of the sweet orange taste discontinuous type temperature-induced phase change gel fragrance-carrying filter stick of the present embodiment is as follows:

[0047] In step (1), the fragrance-carrying substance is composed of seven components including polyethylene glycol, chitosan, sodium carboxymethylcellulose, starch, pectin, sodium alginate and β-cyclodextrin, and each component The ratio is 16:0.6:1:0.1:0.2:0.4:0.4, the weight ratio of fragrance carrier and water is 3:1, heat and stir at 60°C for 0.5h to fully melt, mix evenly, and obtain a mixture with a melting point of 50 ℃ temperature-induced phase change composite colloid, then sweet orange essence, propylene glycol fatty acid ester, and curcumin were added to the prepared composite colloid, and stirred evenly, the weights of the added sweet orange essence, ...

Embodiment 3

[0049] Example 3: Preparation of discontinuous temperature-induced phase change gel fragrance-loaded filter stick with coffee taste

[0050] The preparation of the coffee-taste discontinuous temperature-induced phase-change gel aroma-carrying filter stick of this embodiment is as follows:

[0051] In step (1), the fragrance-carrying substance is composed of polyethylene glycol, chitosan, sodium carboxymethylcellulose, starch, pectin, sodium alginate and β-cyclodextrin, and the ratio of each component is: 16: 0.4:1.1:0.05:0.2:0.45:0.5, heat and stir at 60°C for 1 hour to fully melt, mix evenly to obtain a temperature-induced phase change composite colloid with a melting point of 55°C, and then add coffee essence, propylene glycol fatty acid ester 1. Add the cocoa pigment to the prepared composite colloid, stir evenly, and the weight of the added coffee essence, propylene glycol fatty acid ester, and cocoa pigment accounts for 10%, 1.5% and 1% of the composite colloid weight res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com