Hot melt adhesive and production method thereof

An adhesive and hot-melt technology, applied in the directions of adhesives, adhesive additives, adhesive types, etc., can solve the problems of poor use effect and high production cost, and achieve simple production, low cost and good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

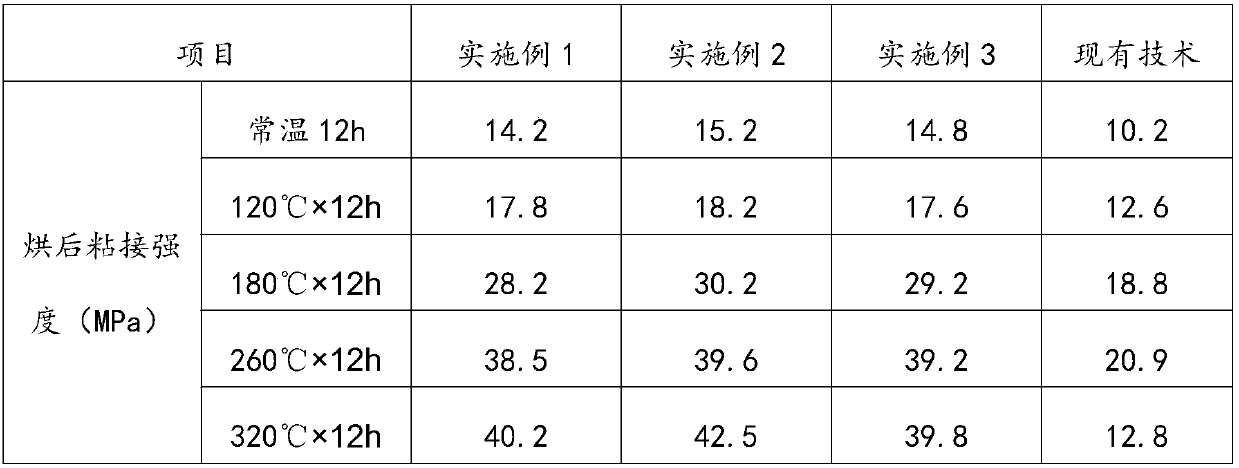

Examples

Embodiment 1

[0020] The hot-melt adhesive of this embodiment is composed of the following raw materials: 10 kg of dibutyl phthalate, 10 kg of triethanolamine, 4 kg of propylene oxide phenyl ether, 8 kg of benzisothiazolone, 2 kg of polyurethane resin, Propyl distarch phosphate 9kg, N-methylpyrrolidone 2kg, hydroxydicumyl peroxide 9kg, furfuryl alcohol resin 1kg, vitamin E oil 10kg and glyoxal 2kg.

[0021] The preparation method of above-mentioned hot-melt adhesive comprises the steps:

[0022] (1) Weigh the following raw materials: dibutyl phthalate 10kg, triethanolamine 10kg, propylene oxide phenyl ether 4kg, benzisothiazolone 8kg, polyurethane resin 2kg, hydroxypropyl distarch phosphate 9kg , N-methylpyrrolidone 2kg, hydroxydicumyl peroxide 9kg, furfuryl alcohol resin 1kg, add to the reaction kettle, gradually heat up, and stir slowly, start timing when the temperature rises to 95°C, keep warm for 10min, and carry out uniform stirring at the same time , until reaching the end of the re...

Embodiment 2

[0025] The hot-melt adhesive of this embodiment is made up of raw materials with the following weight: 15kg of dibutyl phthalate, 7kg of triethanolamine, 7kg of propylene oxide phenyl ether, 5kg of benzisothiazolone, 6kg of polyurethane resin, hydroxy Propyl distarch phosphate 7kg, N-methylpyrrolidone 6kg, hydroxydicumyl peroxide 6kg, furfuryl alcohol resin 3kg, vitamin E oil 7kg and glyoxal 4kg.

[0026] The preparation method of above-mentioned hot-melt adhesive comprises the steps:

[0027] (1) Weigh the following raw materials: dibutyl phthalate 15kg, triethanolamine 7kg, propylene oxide phenyl ether 7kg, benzisothiazolone 5kg, polyurethane resin 6kg, hydroxypropyl distarch phosphate 7kg , 6kg of N-methylpyrrolidone, 6kg of hydroxydicumyl peroxide, and 3kg of furfuryl alcohol resin were added to the reaction kettle, and the temperature was gradually raised, and stirred slowly. When the temperature rose to 95°C, the timing was started, and the temperature was kept for 20 mi...

Embodiment 3

[0030] The hot-melt adhesive of this embodiment is composed of the following raw materials: 20 kg of dibutyl phthalate, 5 kg of triethanolamine, 10 kg of propylene oxide phenyl ether, 2 kg of benzisothiazolone, 10 kg of polyurethane resin, Propyl distarch phosphate 5kg, N-methylpyrrolidone 10kg, hydroxydicumyl peroxide 3kg, furfuryl alcohol resin 5kg, antioxidant 4kg and crosslinking agent 6kg.

[0031] The preparation method of above-mentioned hot-melt adhesive comprises the steps:

[0032] (1) Weigh the following raw materials: dibutyl phthalate 20kg, triethanolamine 5kg, propylene oxide phenyl ether 10kg, benzisothiazolone 2kg, polyurethane resin 10kg, hydroxypropyl distarch phosphate 5kg , 10kg of N-methylpyrrolidone, 3kg of hydroxydicumyl peroxide, and 5kg of furfuryl alcohol resin were added to the reaction kettle, and the temperature was gradually raised, and stirred slowly. When the temperature rose to 95°C, the timing was started, and the temperature was kept for 30 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com