Preparation method of ganoderma sinense culture medium

A culture medium and technology of Zizhi, applied in the preparation of organic fertilizers, botanical equipment and methods, cultivation and other directions, can solve the problems of many types of Ganoderma lucidum, high cost, and many raw material processing procedures, and achieve a simple production process and low production cost. , improve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

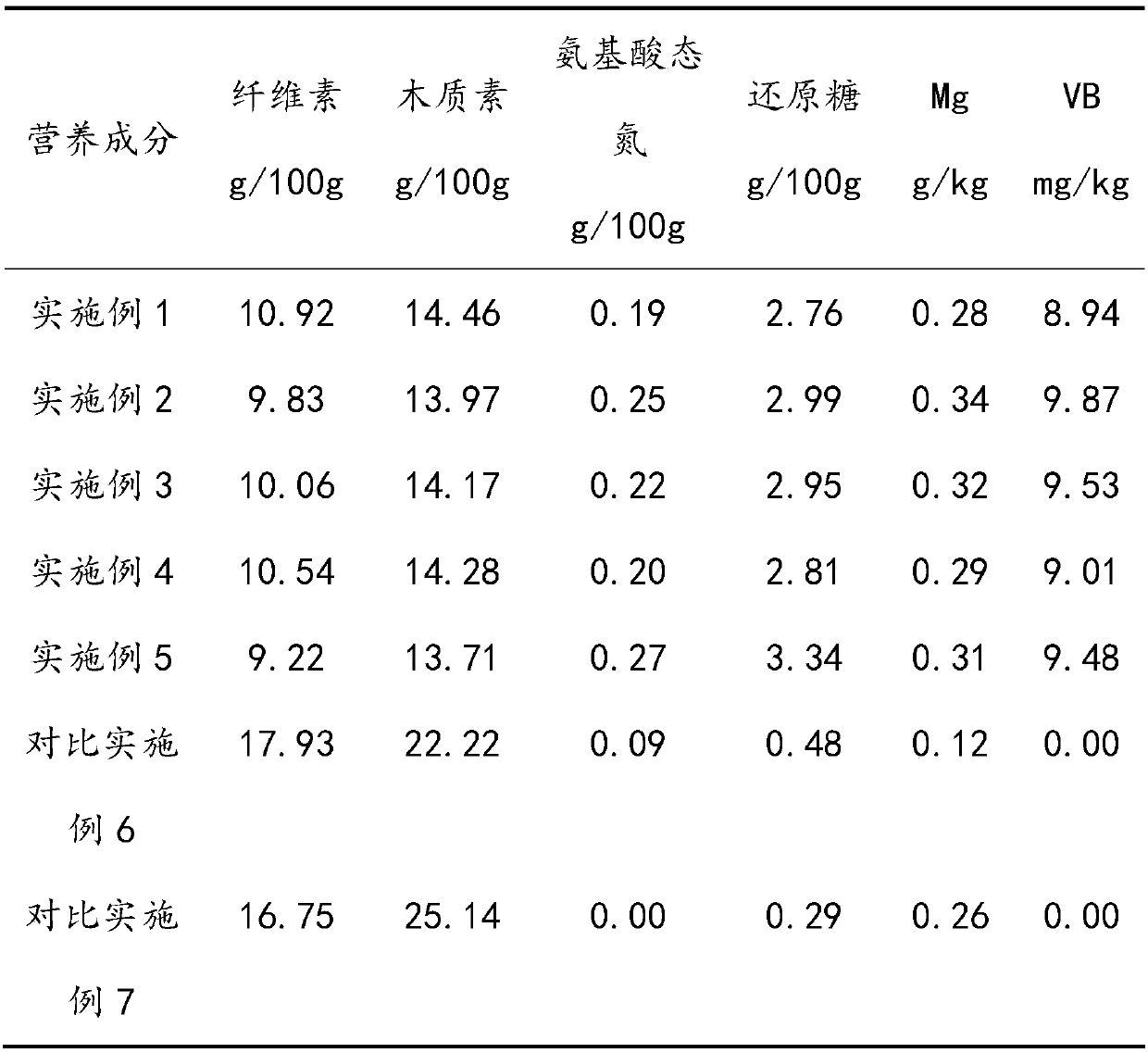

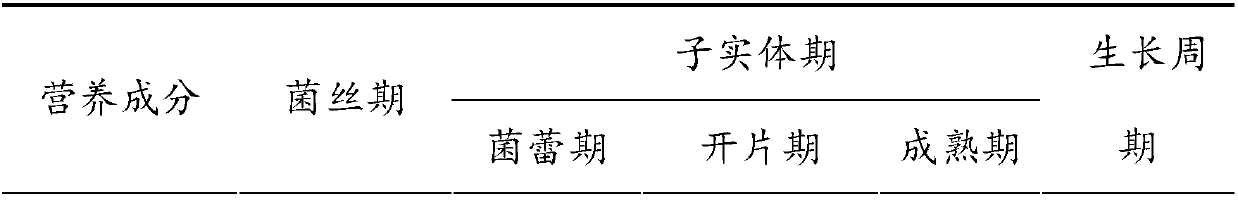

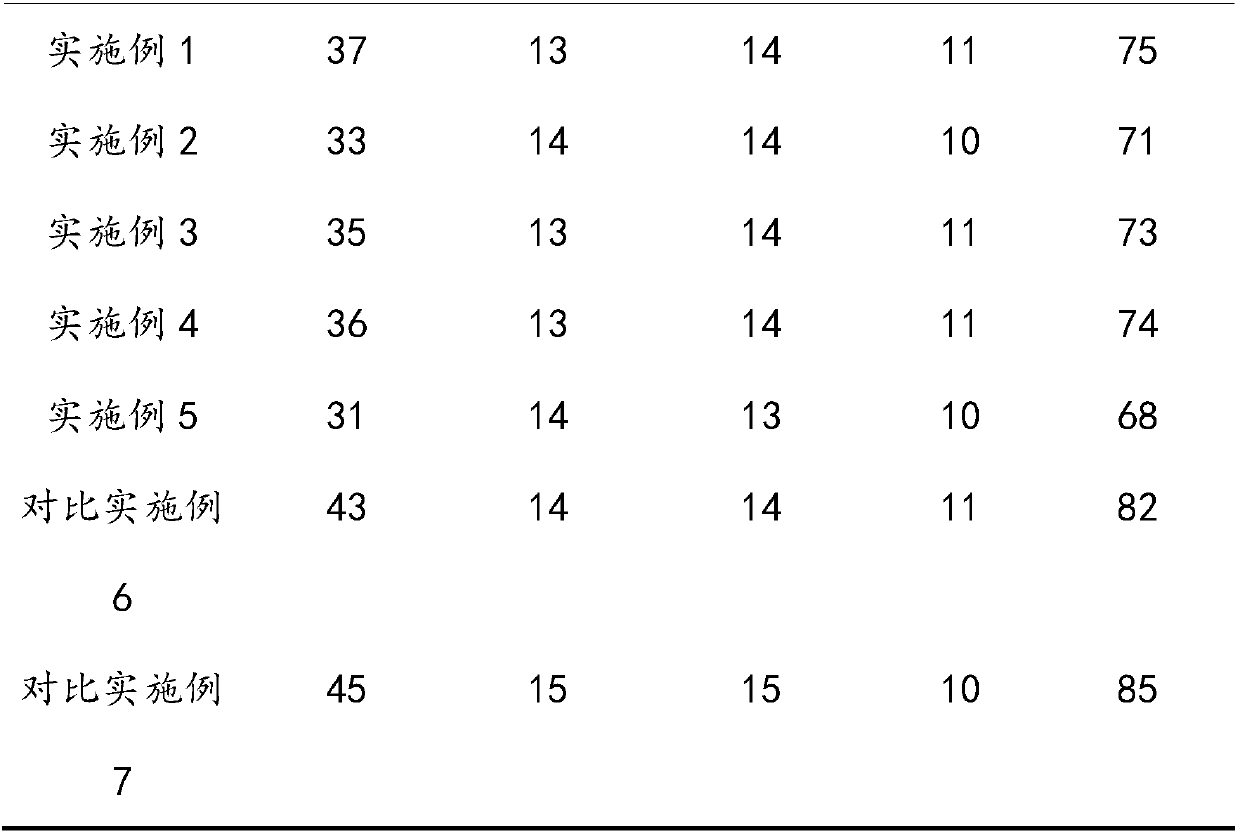

Examples

Embodiment 1

[0024] 1) Take 60kg of wood chips, 35kg of olive pomace obtained after olive fruit oil extraction, and 60kg of drinking water, mix well, let stand for moistening for 25min, move to a steamer and cook for 25min under normal pressure;

[0025] 2) Cool the mixed material cooked in step 1) to 35°C, add 6kg of Aspergillus oryzae bran koji, mix evenly, keep fermenting at 30°C for 38 hours, after the fermentation, add 40kg of drinking water at 50°C, and heat-preserve at 50°C for enzymatic hydrolysis 32h;

[0026] 3) The mixed material after step 2) enzymolysis is finished, bagged: 0.5kg per bag, bag diameter 10cm, bag height 15cm; steam sterilization at normal pressure for 20min, and the preparation of Zizhi culture medium can be directly inoculated with Zizhi. Used to cultivate Zizhi fruiting bodies.

Embodiment 2

[0027] Embodiment 2, with embodiment 1, difference is,

[0028] 1) The amount of drinking water is 75kg, let stand to moisten the water for 38 minutes, move it to a steamer and steam for 33 minutes under normal pressure;

[0029] 2) adding Aspergillus oryzae bran koji for 42 hours of heat preservation and fermentation, and 39 hours of heat preservation and enzymolysis at 54°C.

[0030] Compared with Example 1, the amount and time of wetting water have been increased, and the fermentation and enzymolysis time of Aspergillus oryzae have been prolonged, so that the content of small molecular substances, B vitamins and inorganic salts in the culture medium is greater.

Embodiment 3

[0032] 1) Take 90kg of wood chips, 60kg of olive pomace obtained after olive fruit oil extraction, and 80kg of drinking water, mix them uniformly, let stand to moisten the water for 40min, move to a steamer and cook for 35min under normal pressure;

[0033] 2) Cool the mixed material cooked in step 1) to 35°C, add 10kg of Aspergillus oryzae bran koji, mix evenly, keep fermenting at 33°C for 44 hours, after the fermentation, add 47kg of drinking water at 50°C, and heat-preserve at 55°C for enzymatic hydrolysis 40h;

[0034] 3) The mixed material after step 2) enzymatic hydrolysis is finished, packed into bags: 0.5 kg of material in each bag, with a bag diameter of 10 cm and a bag height of 15 cm; sterilized by atmospheric pressure steam for 20 minutes to prepare a Zizhi culture medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com