A kind of black composite silicon dioxide microsphere and preparation method thereof

A technology of composite silicon dioxide and silicon dioxide, which is applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems affecting the display effect of the display, and achieve the advantages of overcoming the defect of always displaying white, good insulation, and high black-and-white contrast Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1 (the addition of PVP is on the impact of black composite silica microsphere morphology)

[0063] 1) Backflow washing of silica microspheres:

[0064] First, weigh an appropriate amount of silica microspheres and add them into deionized water, and reflux at 110° C. for 2 hours. Then, after replacing the deionized water, the reflux was continued for 2 hours.

[0065] 2) Centrifugal washing of silica microspheres:

[0066] Add silica microspheres and an appropriate amount of deionized water into a centrifuge tube, and perform centrifugal washing by a centrifuge.

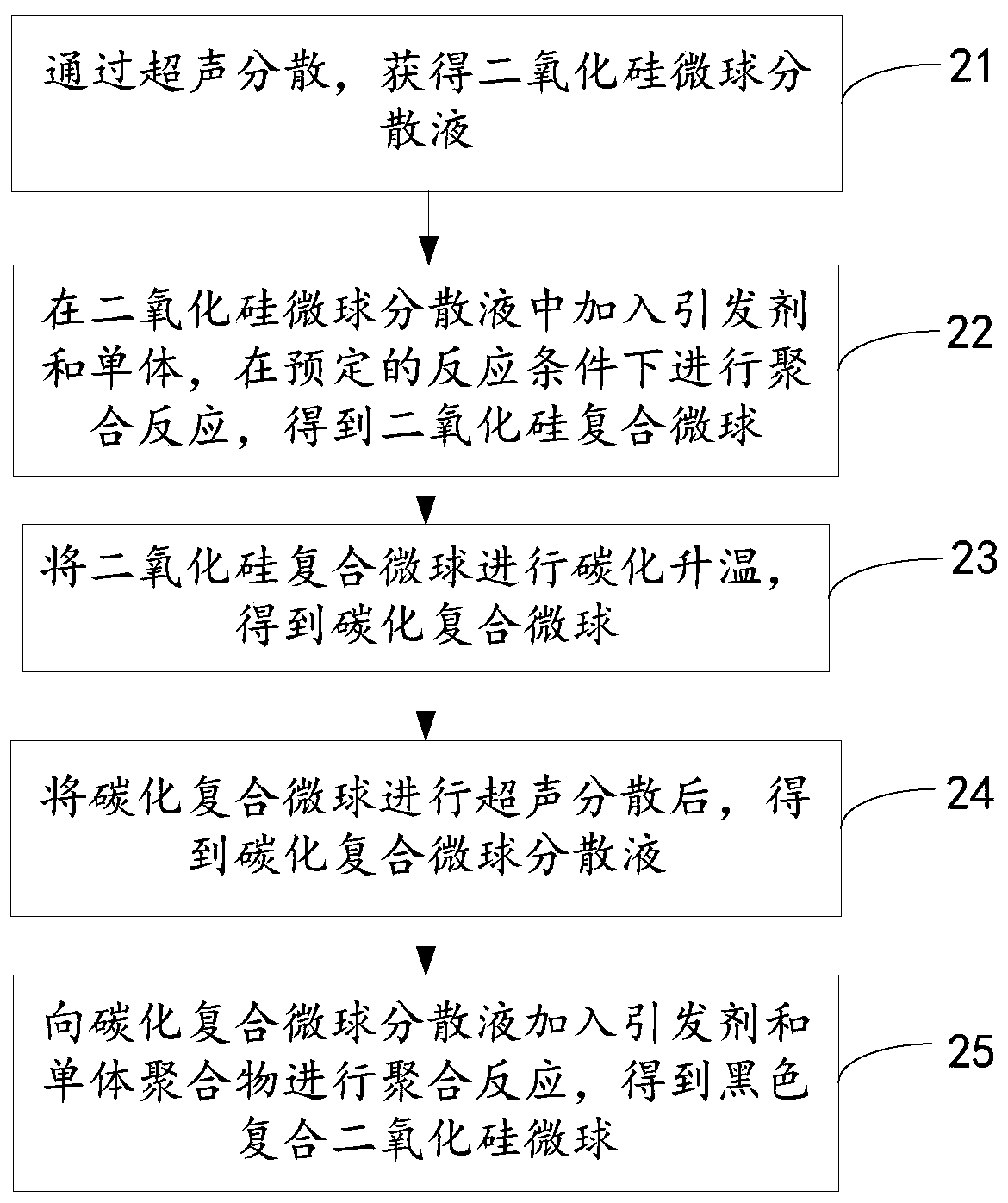

[0067] 3) Ultrasonic dispersion of silica microspheres:

[0068] First, add ethanol to the centrifugally washed centrifuge tube for preliminary ultrasonic dispersion. The volume ratio of ethanol to deionized water is 2:1. Then, add a mixed solution of ethanol and a specified amount of PVP, and continue to ultrasonically disperse for 30-40 minutes to obtain a silica microsphere dispersion.

[00...

Embodiment 2

[0090] Embodiment 2 (initiator and styrene, the impact of the addition amount of polystyrene on the black composite silica microsphere morphology)

[0091] 1) Backflow washing of silica microspheres:

[0092] First, weigh an appropriate amount of silica microspheres and add them into deionized water, and reflux at 110° C. for 2 hours. Then, after replacing the deionized water, the reflux was continued for 2 hours.

[0093] 2) Centrifugal washing of silica microspheres:

[0094] Add silica microspheres and an appropriate amount of deionized water into a centrifuge tube, and perform centrifugal washing by a centrifuge.

[0095] 3) Ultrasonic dispersion of silica microspheres:

[0096] First, preliminary ultrasonic dispersion is performed on the silica microspheres washed by centrifugation. Then, add the mixed solution of ethanol and PVP (the adding weight of PVP is 6% of described silica microsphere weight), continue ultrasonic dispersion 30-40 minute,

[0097] A dispersion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com