A kind of immobilized compound algae microsphere and its application

A technology of compound algae microspheres and microspheres, applied in directions such as being fixed on or in an inorganic carrier, immobilizing on/in an organic carrier, microorganisms, etc. effect and other problems, to achieve the effect of simple and easy preparation process, improved removal capacity, and reasonable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

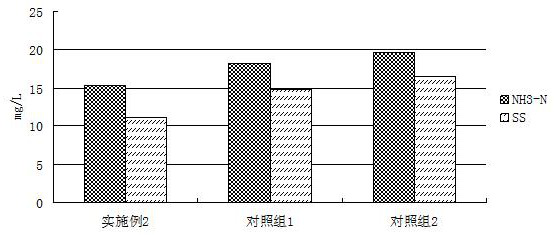

Examples

Embodiment 1

[0031] An immobilized compound algae microsphere, which is prepared according to the following process:

[0032] 1) Take the small Crescent algae in the logarithmic growth phase, centrifuge at 7000rpm for 15min, remove the supernatant, then add sterile water to adjust the density of algae cells to 3×10 7 cell / mL, to obtain the small Crescent algae concentrate;

[0033] 2) Take Scenedesmus obliquus in the logarithmic growth phase, centrifuge at 5000rpm for 15min, remove the supernatant, then add sterile water to adjust the density of algae cells to 2×10 7 cell / mL, to obtain Scenedesmus oblique concentrate;

[0034] 3) Take the Fusarium algae in logarithmic growth phase, centrifuge at 5000rpm for 10min, remove the supernatant, then add sterile water to adjust the density of algae cells to 0.5×10 7 cell / mL, obtain the concentrated solution of Fusarium algae;

[0035] 4) Mix the concentrated liquid of Crescent algae, concentrated liquid of Scenedesmus obliquus and concentrated ...

Embodiment 2

[0039] An immobilized compound algae microsphere, which is prepared according to the following process:

[0040] 1) Take the small Crescent algae in the logarithmic growth phase, centrifuge at 7000rpm for 15min, remove the supernatant, then add sterile water to adjust the density of algae cells to 4×10 7 cell / mL, to obtain the small Crescent algae concentrate;

[0041] 2) Take Scenedesmus obliquus in the logarithmic growth phase, centrifuge at 5000rpm for 15min, remove the supernatant, then add sterile water to adjust the density of algae cells to 3×10 7 cell / mL, to obtain Scenedesmus oblique concentrate;

[0042] 3) Take the Fusarium algae in logarithmic growth phase, centrifuge at 5000rpm for 10min, remove the supernatant, then add sterile water to adjust the density of algae cells to 0.8×10 7 cell / mL, obtain the concentrated solution of Fusarium algae;

[0043]4) Mix the concentrated liquid of Crescent algae, concentrated liquid of Scenedesmus obliquus and concentrated l...

Embodiment 3

[0047] An immobilized compound algae microsphere, which is prepared according to the following process:

[0048] 1) Take the small Crescent algae in the logarithmic growth phase, centrifuge at 7000rpm for 15min, remove the supernatant, then add sterile water to adjust the density of algae cells to 3×10 7 cell / mL, to obtain the small Crescent algae concentrate;

[0049] 2) Take Scenedesmus obliquus in the logarithmic growth phase, centrifuge at 5000rpm for 15min, remove the supernatant, then add sterile water to adjust the density of algae cells to 3×10 7 cell / mL, to obtain Scenedesmus oblique concentrate;

[0050] 3) Take the Fusarium algae in the logarithmic growth phase, centrifuge at 5000rpm for 10min, remove the supernatant, then add sterile water to adjust the density of algae cells to 0.5×10 7 cell / mL, obtain the concentrated solution of Fusarium algae;

[0051] 4) Mix the concentrated liquid of Crescent algae, concentrated liquid of Scenedesmus obliquus and concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com