A Thin Film Doping Modification Method Based on Plasma Enhanced Atomic Layer Deposition

An atomic layer deposition and plasma technology, applied in the field of thin film doping, can solve the problems of unsatisfactory quality, poor optical and mechanical properties of thin films, etc., and achieve strong applicability, convenient operation and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

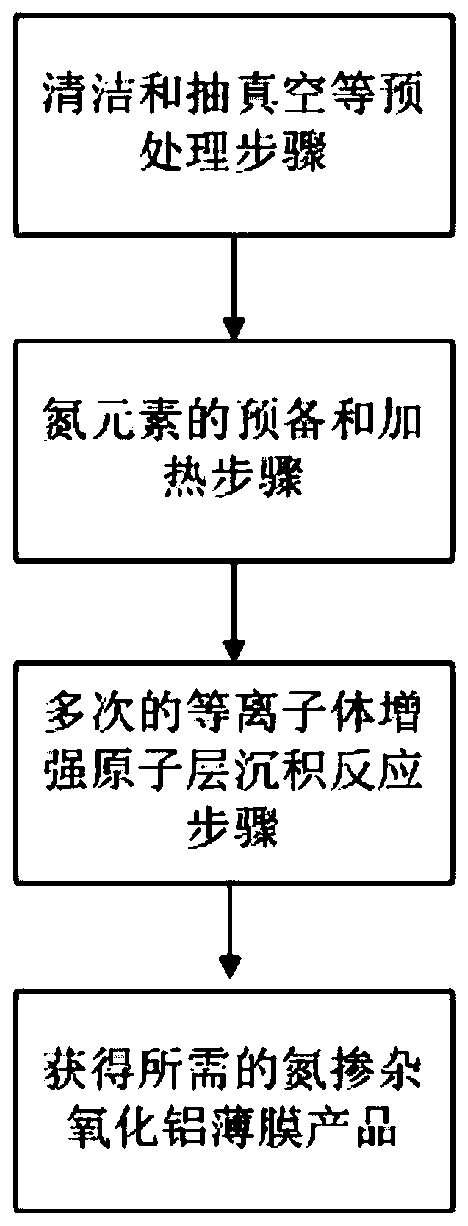

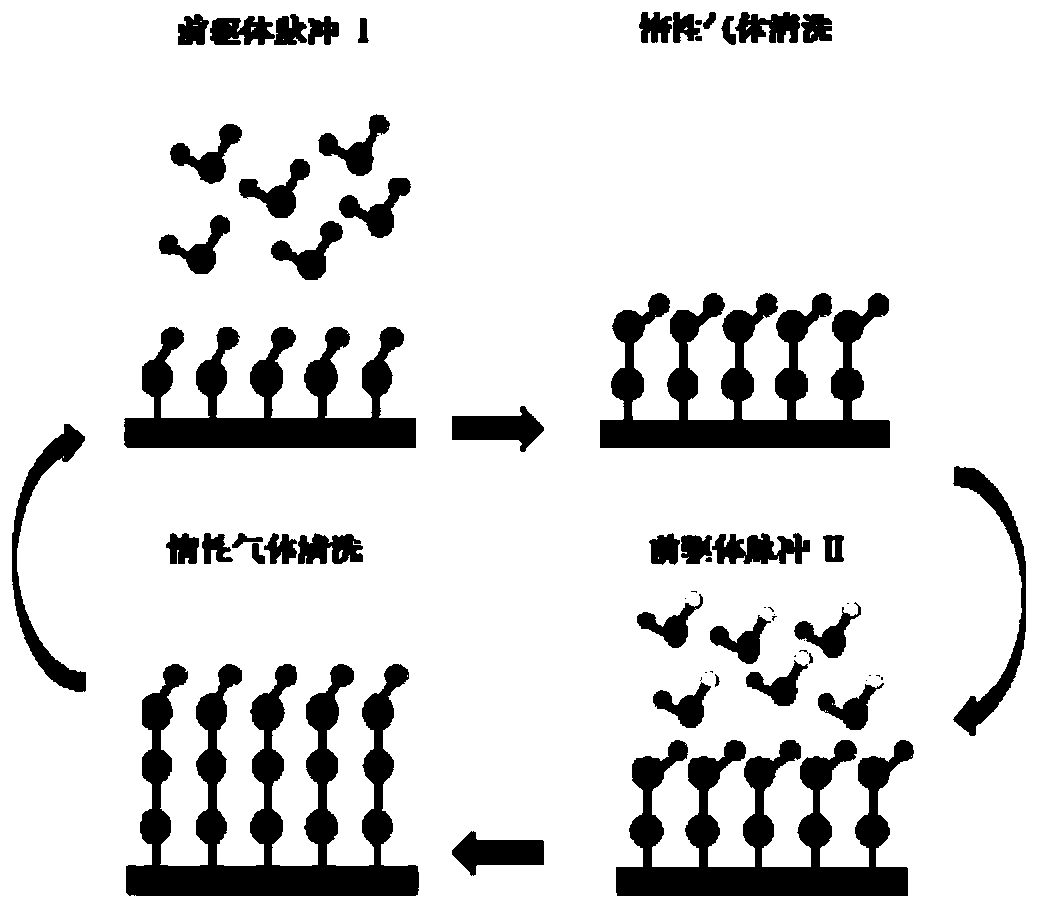

Method used

Image

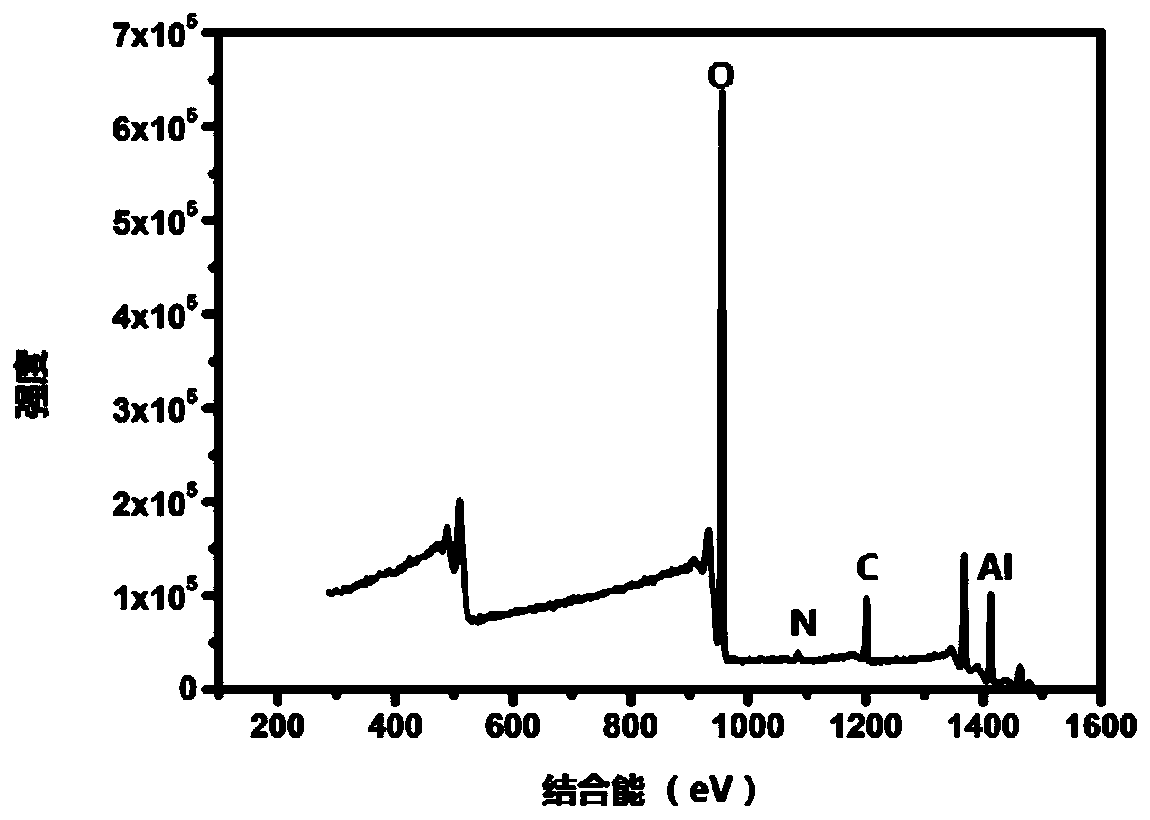

Examples

Embodiment 1

[0045] Using plasma-enhanced atomic layer deposition technology, 20 cycles of nitrogen-doped aluminum oxide were grown on the surface of the silicon wafer substrate. The method includes the following processes:

[0046] First, use high-pressure nitrogen to purge the substrate silicon wafer to be deposited, put the silicon wafer into the cavity of the plasma-enhanced atomic layer deposition reactor, cover the cavity, turn on the switch of the vacuum pump for vacuuming, and set the pressure at the outlet of the cavity 1 Pa;

[0047] One or more of high-purity nitrogen or high-purity ammonia is loaded at the gas inlet of the plasma equipment, and the plasma generation equipment is turned on when the deposition starts; the chamber is heated, and the temperature of the reaction chamber is set to 60°C. During the process, the inert gas argon is continuously fed into the cavity at 50 standard milliliters per minute as a cleaning gas to clean the cavity; the cavity outlet pressure is ...

Embodiment 2

[0054] A 20-period nitrogen-doped aluminum oxide was grown on the surface of a silicon wafer substrate by plasma-enhanced atomic layer deposition, and the method included the following processes:

[0055] Use high-pressure nitrogen to purge the substrate silicon wafer to be deposited, put the silicon wafer into the chamber of the plasma-enhanced atomic layer deposition reactor, cover the chamber, turn on the switch of the vacuum pump to vacuumize, and the outlet pressure of the chamber is 2Pa;

[0056] One or more of high-purity nitrogen or high-purity ammonia is loaded at the gas inlet of the plasma equipment, and the plasma generation equipment is turned on when the deposition starts; the chamber is heated, and the temperature of the reaction chamber is set to 100°C. During the process, the inert gas argon is continuously fed into the cavity at 50 standard milliliters per minute as a cleaning gas to clean the cavity; the cavity outlet pressure is 40Pa;

[0057] When the temp...

Embodiment 3

[0063] Using plasma-enhanced atomic layer deposition technology to grow 140 cycles of nitrogen-doped aluminum oxide on the surface of the silicon wafer substrate, the method includes the following processes:

[0064] Use high-pressure nitrogen to purge the substrate silicon wafer to be deposited, put the silicon wafer into the cavity of the plasma-enhanced atomic layer deposition reactor, cover the cavity, turn on the switch of the vacuum pump to vacuumize, and the outlet pressure of the cavity is 0.5Pa;

[0065] One or more of high-purity nitrogen or high-purity ammonia is loaded at the gas inlet of the plasma equipment, and the plasma generation equipment is turned on when the deposition starts; the chamber is heated, and the temperature of the reaction chamber is set to 25°C. During the process, the inert gas argon is continuously fed into the cavity at 50 standard milliliters per minute as a cleaning gas to clean the cavity; the cavity outlet pressure is 20Pa;

[0066] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com