Preparation method of kapok-based hollow porous carbon microtubule or porous carbon microstrip

A porous carbon and kapok-based technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of underdeveloped gaps, low specific power, and poor rate performance of activated carbon electrodes, and achieve excellent capacitance performance and rate Improved performance, specific energy and rate performance, and better capacitance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

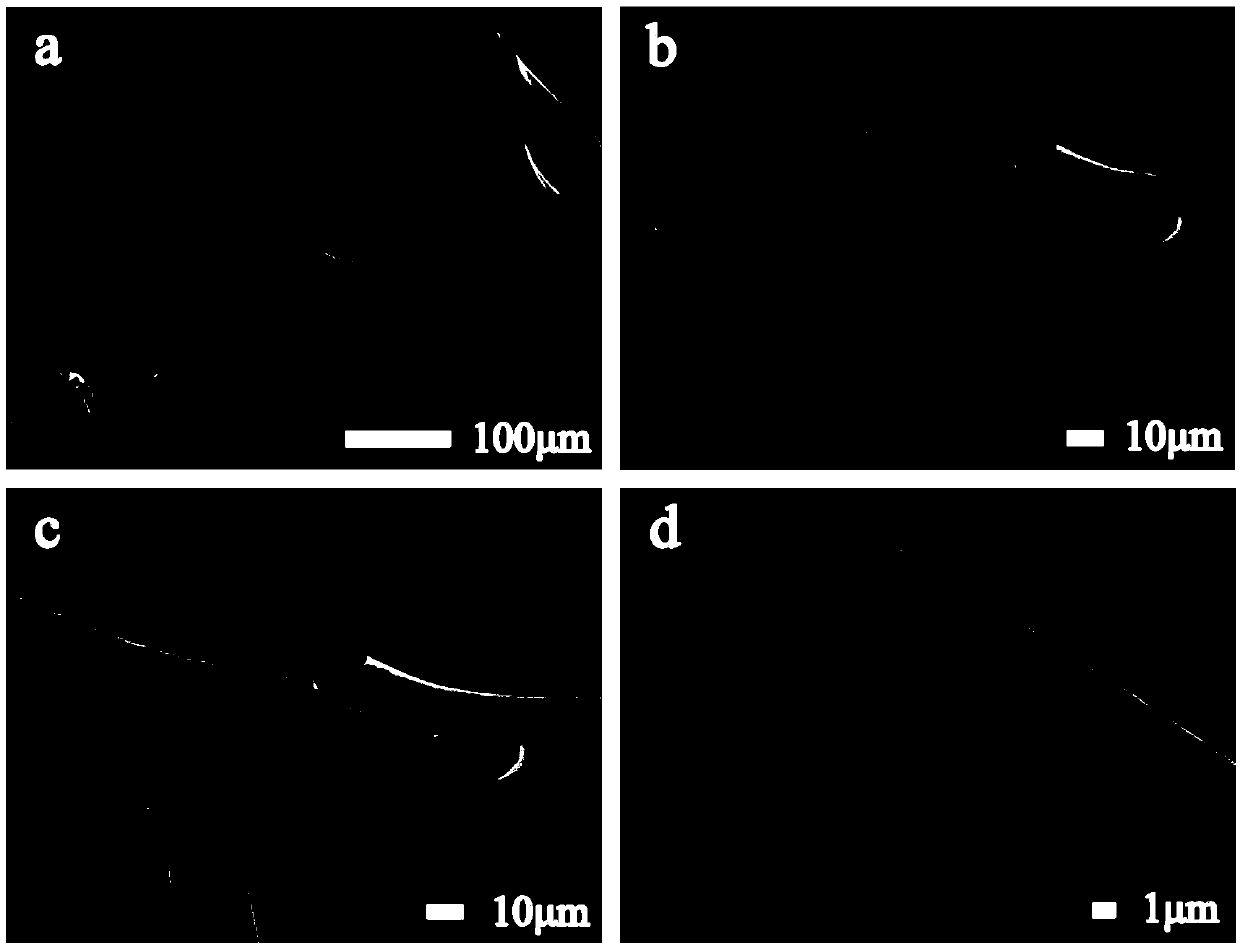

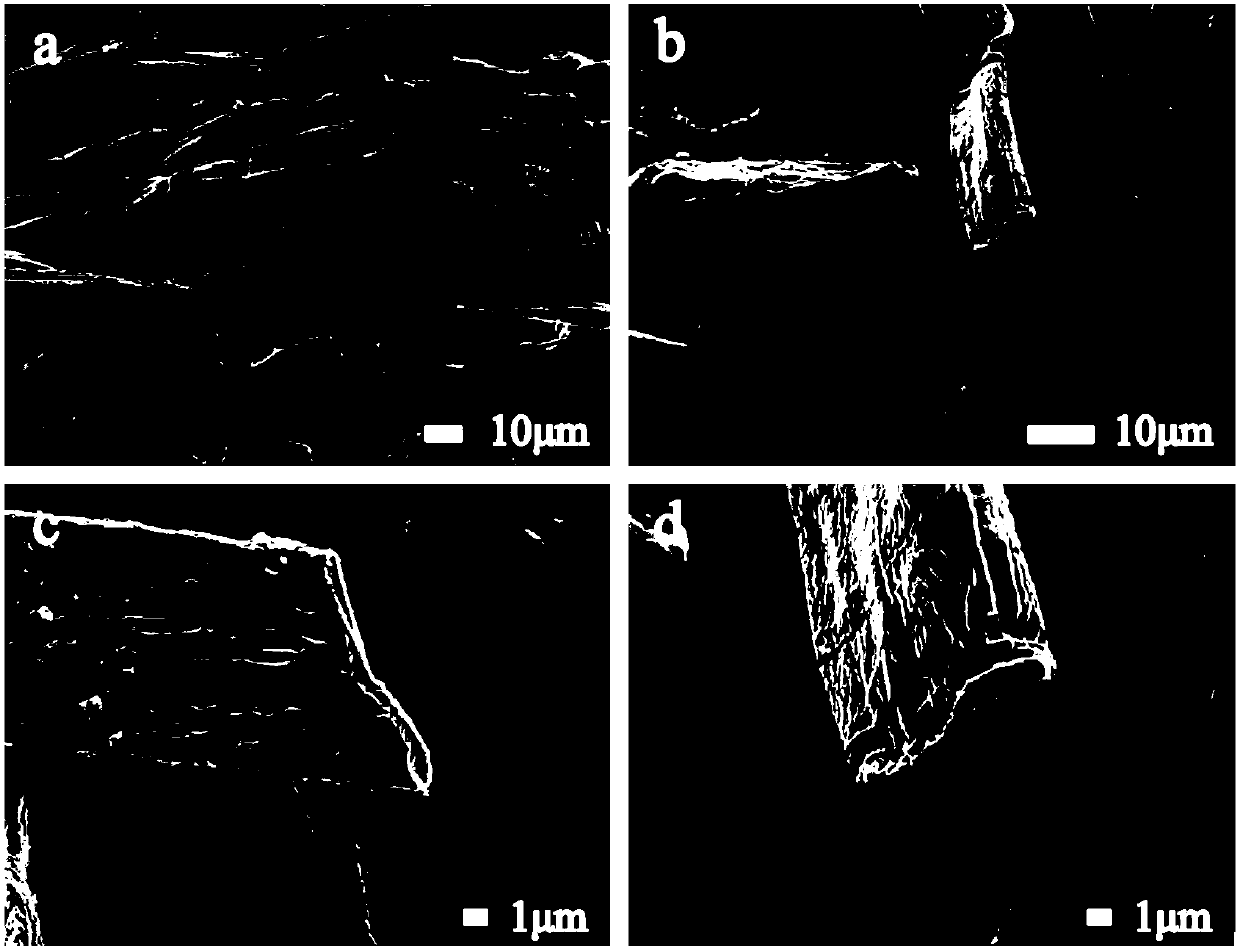

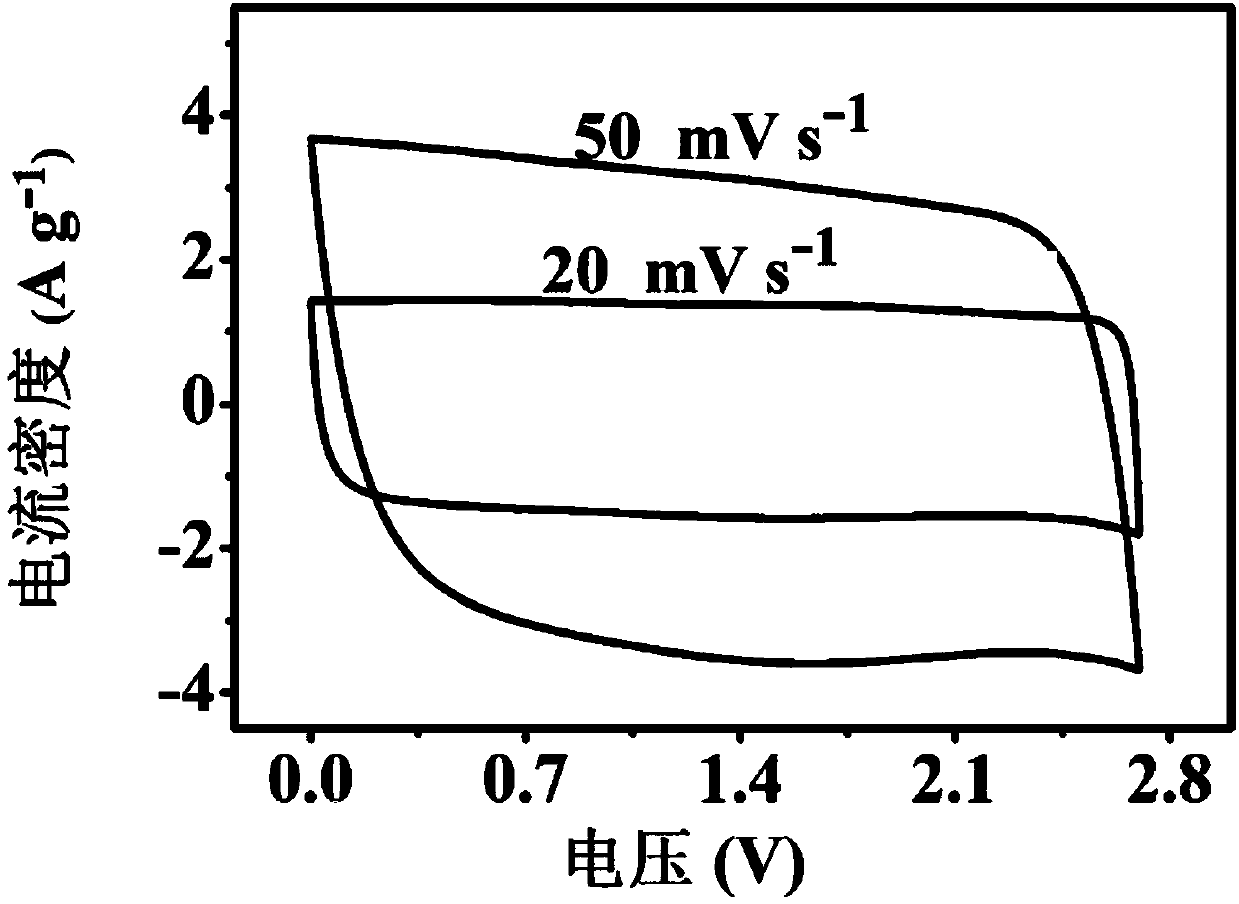

[0032] (1) Ultrasound (power 100W) disperse kapok in a mixed solution composed of ethanol and 1.0wt% sodium chlorite solution (volume ratio of ethanol to sodium chlorite solution 1:2), soak for 3h, and then Ionized water cleaning, filtration, vacuum drying (temperature 60℃, drying time 15h) to obtain clean tubular kapok; or using ultrasound (power 100W) to disperse the kapok in a sodium hydroxide solution with a concentration of 1.0wt% and soak for 2h, Then filter and vacuum dry (temperature 60℃, drying time 15h) to get clean ribbon kapok;

[0033] (2) Vacuum immerse the above clean tubular kapok or ribbon kapok in a 3wt.% hydrogen phosphate diamine solution (relative vacuum degree of 0.7), and the mass ratio of kapok to hydrogen phosphate diamine is 1:1, followed by After immersing for 12 hours at 105℃ and drying at 105℃, the dried product obtained is pre-oxidized at low temperature under flowing air (to make the pre-oxidation more fully). The constant temperature is 200℃, and t...

Embodiment 2

[0037] (1) Ultrasonic (power 300W) disperse kapok in a mixed solution composed of ethanol and 1.3wt% sodium chlorite solution (volume ratio of ethanol to sodium chlorite solution 1:4), soak for 3h, and then Ionized water cleaning, filtration, vacuum drying (temperature 60℃, drying time 15h) to obtain clean tubular kapok; or using ultrasound (power 300W) to disperse the kapok in a sodium hydroxide solution with a concentration of 2.0wt% and soak for 2h, Then filter and vacuum dry (temperature 60℃, drying time 15h) to get clean ribbon kapok;

[0038] (2) Vacuum immerse the above clean tubular kapok or ribbon kapok in a 5wt.% hydrogen phosphate diamine solution (relative vacuum degree of 0.85), and the mass ratio of kapok to hydrogen phosphate diamine is 1:3. After immersing for 12 hours at 105℃ and drying at 105℃, the dried product obtained is pre-oxidized at low temperature under flowing air (to make the pre-oxidation more fully). The constant temperature is 250℃, and the heating ...

Embodiment 3

[0042] (1) Ultrasonic (power 500W) disperse kapok in a mixed solution composed of ethanol and 1.5wt% sodium chlorite solution (volume ratio of ethanol to sodium chlorite solution 1:6), soak for 3h, and then remove Ionized water cleaning, filtration, vacuum drying (temperature 60℃, drying time 15h) to obtain clean tubular kapok; or using ultrasound (power 500W) to disperse the kapok in a sodium hydroxide solution with a concentration of 2.0wt% and soak for 2h, Then filter and vacuum dry (temperature 60℃, drying time 15h) to get clean ribbon kapok;

[0043] (2) The above clean tubular kapok or ribbon kapok is vacuum immersed in a 7wt.% hydrogen phosphate diamine solution (relative vacuum degree 0.9), and the mass ratio of kapok to hydrogen phosphate diamine is 1:5. After immersing for 12 hours at 105℃ and drying at 105℃, the dried product obtained is pre-oxidized at low temperature under flowing air (to make the pre-oxidation more fully). The constant temperature is 250℃, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com