Nano cerium dioxide and preparation method thereof

A nano-ceria, cerium nitrate technology, applied in chemical instruments and methods, nanotechnology, rare earth metal oxides/hydroxides, etc., can solve the problems of complex preparation methods of nano-ceria, and achieve good application prospects, The effect of avoiding agglomeration and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Dissolve 2.21g of KH550 in 45mL of distilled water, and add 4.34g of cerium nitrate under stirring until completely dissolved to obtain solution A. Then 4.24g of cerium nitrate was dissolved in 45ml of distilled water, and 2.21g of KH550 was added to obtain solution B with precipitation.

[0044] (2) The above solution A and solution B were transferred to a 60mL stainless steel hydrothermal reaction kettle with a Teflon lining and sealed, placed in an oven, heated to 140°C, and hydrothermally reacted for 24 hours.

[0045] (3) After the reaction is completed, after cooling to room temperature, the obtained pale yellow solid precipitate is centrifuged and washed three times with distilled water, washed twice with ethanol, and finally vacuum-dried at 45°C for 8 hours, and ground to obtain spherical nano-dioxide with ultra-small particle size. Cerium particles.

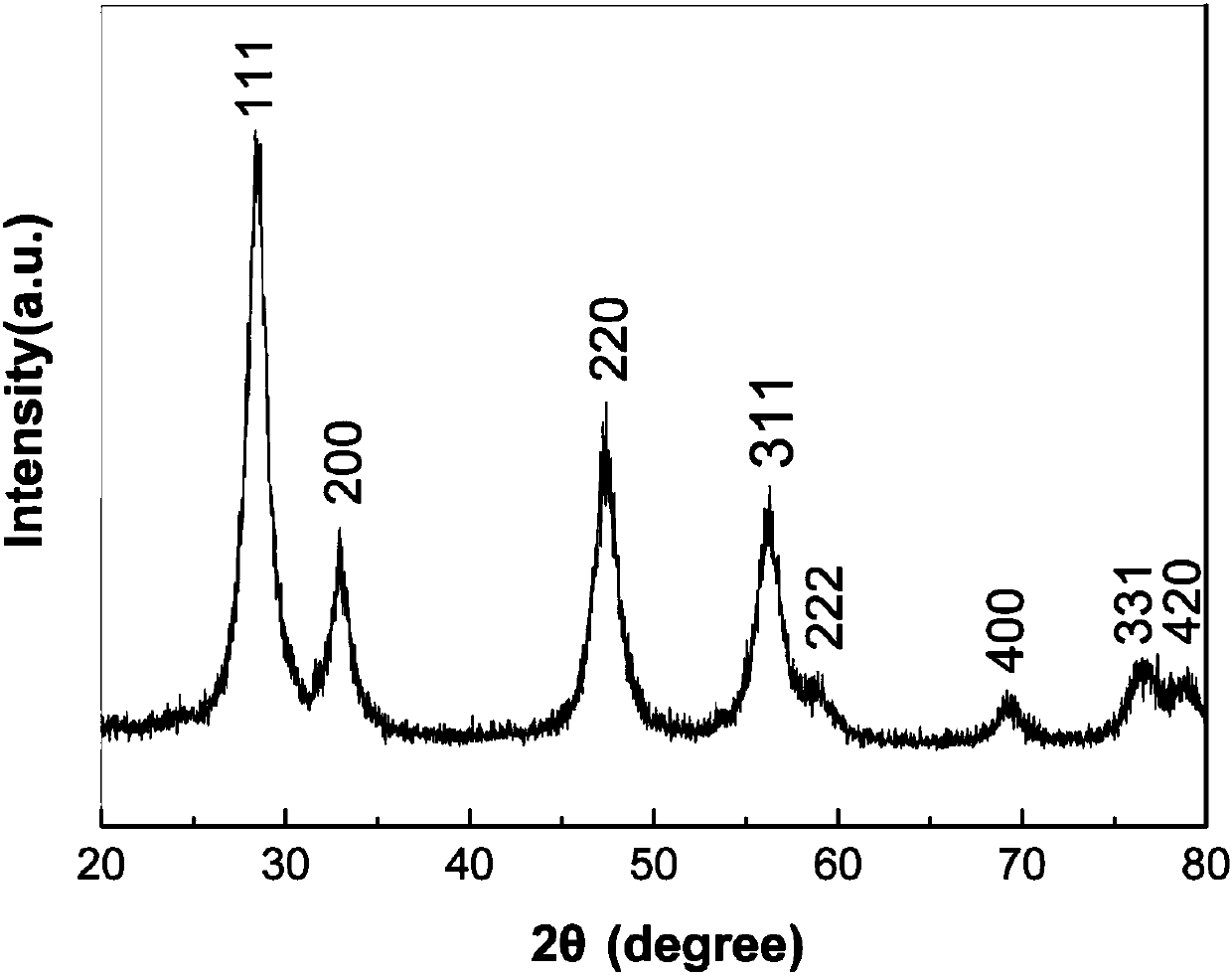

[0046] figure 1 For the XRD spectrum of the ceria nanoparticles prepared for this embodiment, the crystal...

Embodiment 2

[0050] (1) Dissolve 1.10g of KH550 in 45mL of distilled water, and add 2.17g of cerium nitrate under stirring until completely dissolved. Then 4.24g of cerium nitrate was dissolved in 45ml of distilled water, and 2.21g of KH550 was added to obtain solution B with precipitation.

[0051] (2) The above solution A and solution B were transferred to a 60mL stainless steel hydrothermal reaction kettle with a Teflon lining and sealed, placed in an oven, heated to 100°C, and hydrothermally reacted for 48 hours.

[0052] (3) After the reaction is completed, after cooling to room temperature, the obtained pale yellow solid precipitate is centrifuged and washed three times with distilled water, washed twice with ethanol, and finally vacuum-dried at 30°C for 18 hours, and ground to obtain spherical nano-dioxide with ultra-small particle size. Cerium particles.

[0053] image 3 The TEM image of the ceria nanoparticles prepared in this example, the particle size of the nanospheres is 3-...

Embodiment 3

[0057] (1) Dissolve 1.10g of KH550 in 45mL of distilled water, and add 4.34g of cerium nitrate under stirring until completely dissolved. Then 4.24g of cerium nitrate was dissolved in 45ml of distilled water, and 2.21g of KH550 was added to obtain solution B with precipitation.

[0058] (2) The above solution A and solution B were transferred to a 60mL stainless steel hydrothermal reaction kettle with a Teflon lining and sealed, placed in an oven, heated to 140°C, and hydrothermally reacted for 12 hours.

[0059] (3) After the reaction is completed, after cooling to room temperature, the obtained pale yellow solid precipitate is centrifuged and washed three times with distilled water, washed twice with ethanol, and finally vacuum-dried at 50°C for 5 hours, and ground to obtain spherical nano-dioxide with ultra-small particle size. Cerium particles.

[0060] Figure 5 The TEM image of the ceria nanoparticles prepared for this example shows that the nanospheres have a particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com