Device for continuously rectifying and refining cyanoacetate and technology thereof

A technology of esterification and cyanoacetic acid, which is applied in the field of continuous rectification and refining of cyanoacetate and equipment for continuous rectification and purification of cyanoacetate, which can solve the problems of low purity, high energy consumption, and high cost of malonate problems, to achieve the effect of easy automatic operation, high yield and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

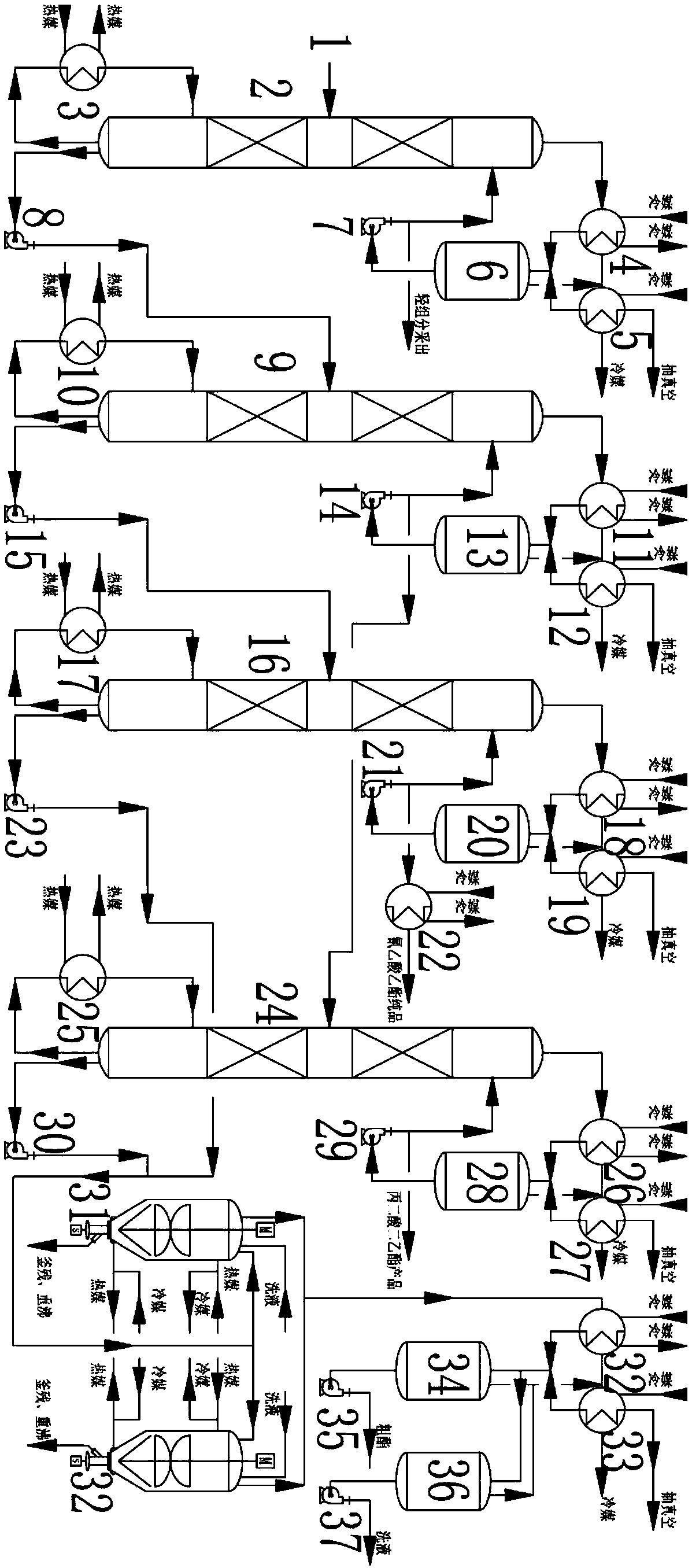

[0030] Such as figure 1 As shown, a continuous rectification and refining cyanoacetic acid esterification device includes a light removal tower 2, a malonate first-stage rectification tower 9, a cyanoacetic acid ester product tower 16, and a malonate The second stage rectification tower 24, the recovery tank 31, and the recovery tank condenser 32; the second stage of the light removal tower 2 is connected to the middle of the first stage rectification tower 9 of the malonate compound, and the top of the light reduction tower 2 is The top condenser 4 and the light removal tower top catcher 5 are connected with a light removal tower top reflux tank 6, and the bottom of the light removal tower top reflux tank 6 is connected to the light removal tower 2 via a light removal tower top reflux pump 7 The top of the tower; the malonate first-stage rectification tower 9 is connected to the middle of the cyanoacetic acid ester product tower 16, and the top of the malonate first-stage rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com